Porous chitosan microcarrier as well as preparation method and application thereof

A technology of porous chitosan and microcarriers, applied in the direction of microcarriers, general culture methods, biochemical equipment and methods, etc., can solve the problem of inability to form cell-cell connections, inability to support a large number of cell growth, unfavorable cell adhesion and growth To achieve good biocompatibility, uniform size, maintain vitality and function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

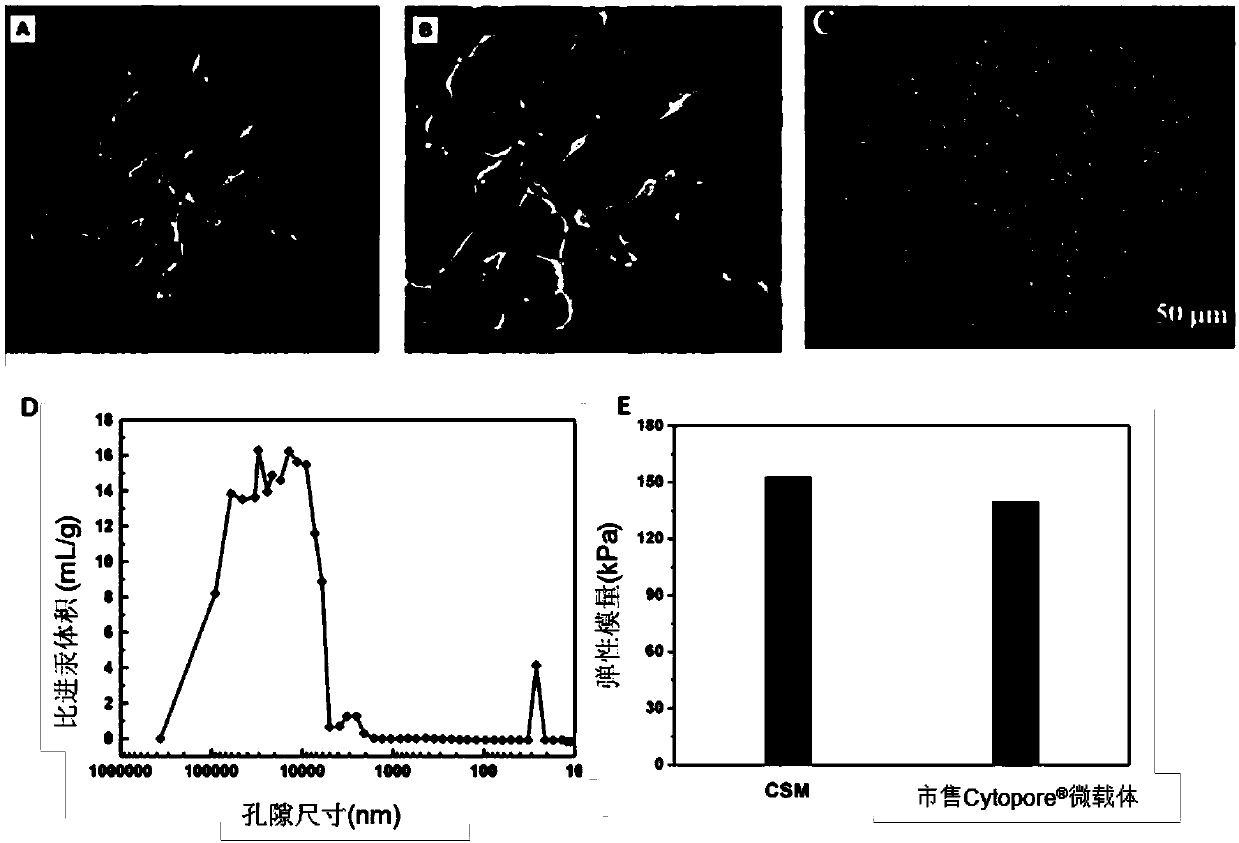

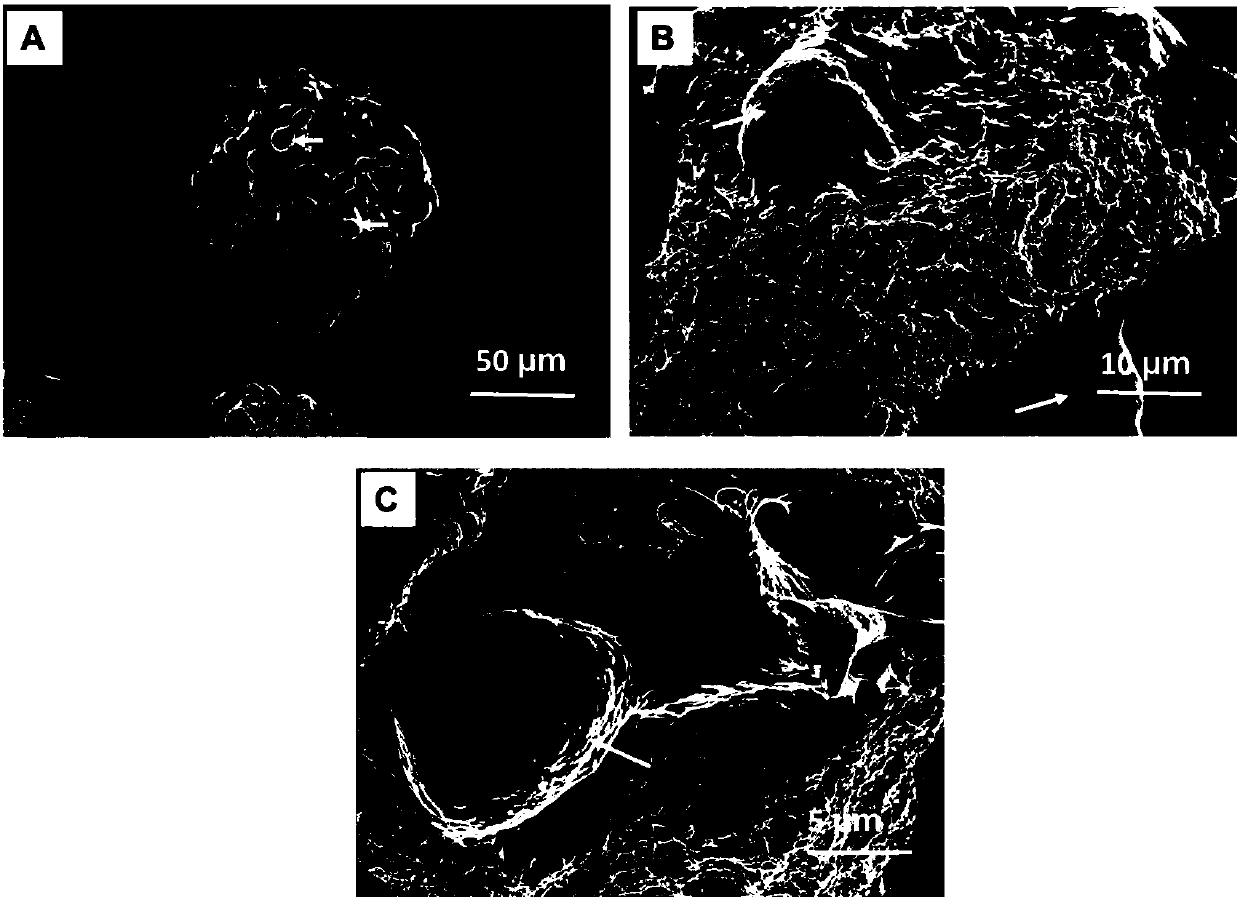

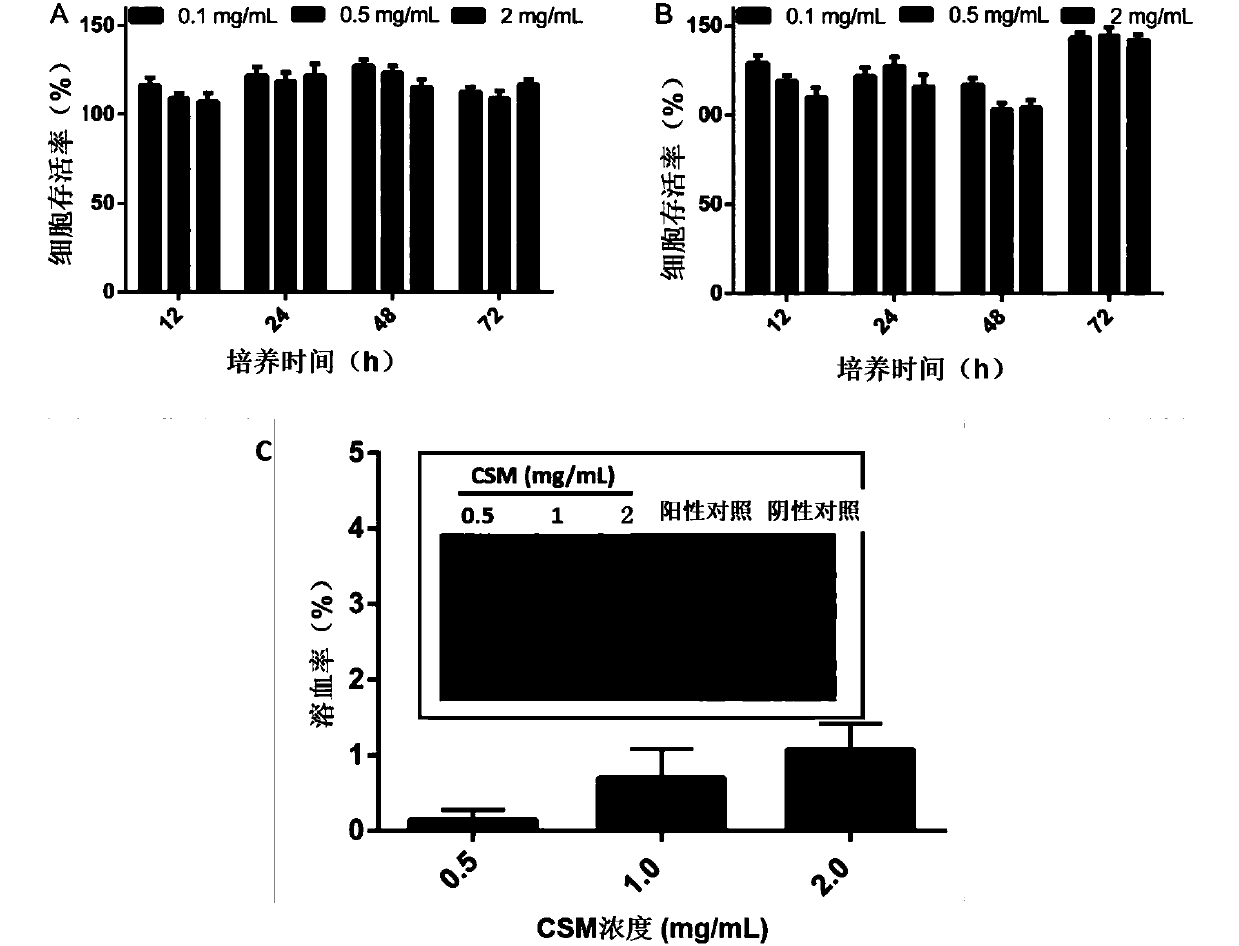

[0046] The preparation of embodiment 1 porous chitosan microcarrier

[0047] 1, prepare 1% (w / v) chitosan deacetylation degree 95%, viscosity-average molecular weight 100,000 (supplier is ) of acetic acid aqueous solution as the dispersed phase, wherein the acetic acid content is 1% (w / v); the petroleum ether solution of the preparation 5% (w / v) emulsifier is used as the continuous phase, wherein the emulsifier is composed of Span 80 and Tween 60 according to 20:1 (w / w) mixed composition; prepare 1% (w / v) ethanol / water solution of sodium hydroxide as a phase transition solution, wherein the ratio of ethanol to water is 14:1 (v / v).

[0048] 2. Slowly add 10 mL of the above dispersed phase solution into 50 mL of the continuous phase solution, and emulsify at 40°C for 4 hours under stirring at 1000 r / min to obtain a W / O emulsion.

[0049] 3. The resulting W / O emulsion was quenched at -20°C for 4 hours to conduct thermally induced phase separation.

[0050] 4. Pour 100mL of the...

Embodiment 2

[0052] The preparation of embodiment 2 porous chitosan microcarriers

[0053] 1, the acetic acid aqueous solution of preparation 1% (w / v) chitosan (deacetylation degree 95%, viscosity-average molecular weight 100,000) is as dispersed phase, wherein acetic acid content 1% (w / v); Preparation 7% (w / v) / v) Petroleum ether solution of emulsifier as continuous phase, wherein emulsifier is composed of Span 80 and Tween 60 mixed in 24:1 (w / w); prepare 1.5% (w / v) ethanol / water solution of sodium hydroxide as Phase change liquid, wherein the ratio of ethanol to water is 20:1 (v / v).

[0054] 2. Slowly add 10 mL of the above dispersed phase solution into 30 mL of the continuous phase solution, and emulsify at 30°C for 4 hours under stirring at 1000 r / min to obtain a W / O emulsion.

[0055] 3. The resulting W / O emulsion was quenched at -50°C for 2 hours to conduct thermally induced phase separation.

[0056] 4. Pour 80mL of the above-mentioned phase transition liquid into the above-mentio...

Embodiment 3

[0058] The preparation of embodiment 3 porous chitosan microcarriers

[0059] 1, prepare 3% (w / v) chitosan (deacetylation degree is greater than 80%, viscosity-average molecular weight 150,000, supplier is ) of acetic acid aqueous solution as the dispersed phase, wherein the acetic acid content is 3% (w / v); the petroleum ether solution of the preparation 7% (w / v) emulsifier is used as the continuous phase, wherein the emulsifier is composed of Span 80 and Tween 60 according to 24:5 (w / w) mixed composition; 3% (w / v) sodium hydroxide ethanol / water solution was prepared as a phase transition solution, wherein the ratio of ethanol to water was 20:5 (v / v).

[0060] 2. Slowly add 10 mL of the above dispersed phase solution into 100 mL of the continuous phase solution, and emulsify at 50°C and 1500 r / min for 2 hours to obtain a W / O emulsion.

[0061] 3. The resulting W / O emulsion was quenched at -5°C for 6 hours to conduct thermally induced phase separation.

[0062] 4. Pour 110mL...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com