Preparation method of high-elasticity and easy-to-stick polyurethane-urea fibers

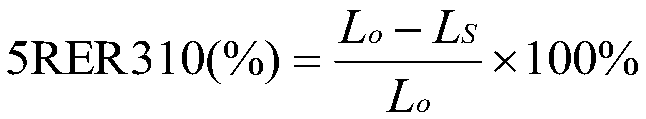

A polyurethane urea and easy-adhesive technology, which is applied in the preparation of highly elastic and easy-adhesive polyurethane urea fibers and the manufacture of new functionalized spandex, can solve the problems of being unable to have both high adhesiveness and high resilience, and achieve good Resilience performance, increased affinity, and excellent resilience effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

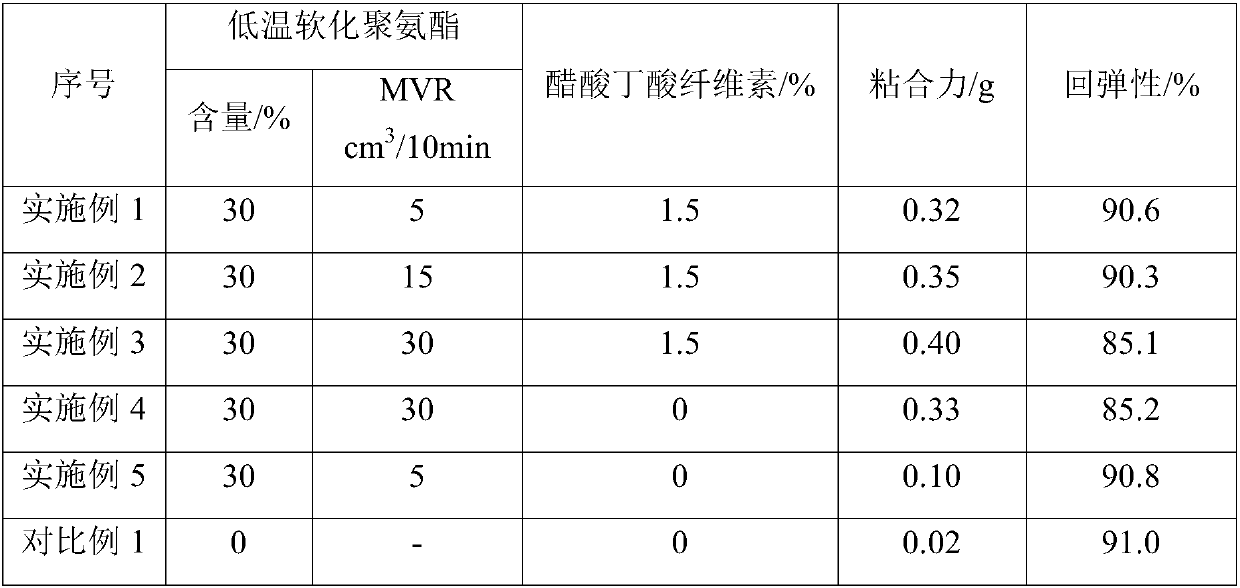

Embodiment 1

[0050] 1) Add polytetramethylene ether glycol with a number average molecular weight of 1810, 4,4'-diphenylmethane diisocyanate and N,N-dimethylacetamide into the reactor to form a 69% mass fraction of solution, and reacted at 45°C for 120 minutes to prepare a prepolymer. After the prepolymer is cooled to 8°C, chain extension reaction is carried out with a mixed amine solution of ethylenediamine and diethylamine having a mass fraction of 5.5%, wherein the molar ratio of ethylenediamine to diethylamine is 20 :1. According to the solid content of polyurethane urea elastic fiber, 0.5wt% of 2-(2'-hydroxyl-3', 5'-di-tert-butylphenyl)-benzotriazole), 0.5wt% of bis(N, Add N-dimethylhydrazideamino4-phenyl)methane, 0.18wt% magnesium stearate, and 0.3wt% titanium dioxide into the stock solution, and stir thoroughly to obtain polyurethaneurea stock solution A with a solid content of 35%.

[0051] 2) set the melt flow rate to 5cm 3 / 10min of low-temperature softening polyurethane, cell...

Embodiment 2

[0054] Spandex fiber is prepared according to the same method described in Example 1, the difference is that the low-temperature softening polyurethane melt flow rate is 15cm 3 / 10min.

Embodiment 3

[0056] Spandex fiber is prepared according to the same method described in Example 1, the difference is that the low-temperature softening polyurethane melt flow rate is 30cm 3 / 10min.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| elastic recovery rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com