Nano additive as well as preparation method and application thereof

A nano-additive, functional group technology, applied in adhesive additives, polymer adhesive additives, transportation and packaging, etc., can solve problems such as excess, high hysteresis loss, and deterioration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] A preparation method of nano-additive, comprising the following steps:

[0045] (1) Take short-chain carboxylic acid with functional group and alkali and place it in a polar solvent, react by heating until the solution is completely transparent, and obtain solution A of short-chain carboxylate product with functional group;

[0046] (2) Take the polymer with carboxylic acid and alkali and place it in a polar solvent, heat the reaction until the solution is completely transparent, and obtain the solution B of the polymer salt with carboxylic acid;

[0047] (3) The mixed solution of solution A and solution B is used as reaction solution C, and under stirring conditions, metal M salt solution is poured into solution C, and the reaction obtains a solid product, which is filtered, washed, and dried to obtain the target product nano-additive ;

[0048] The structural formula of the short-chain carboxylic acid with a functional group is HOOC-F;

[0049] The short-chain carbo...

Embodiment 1

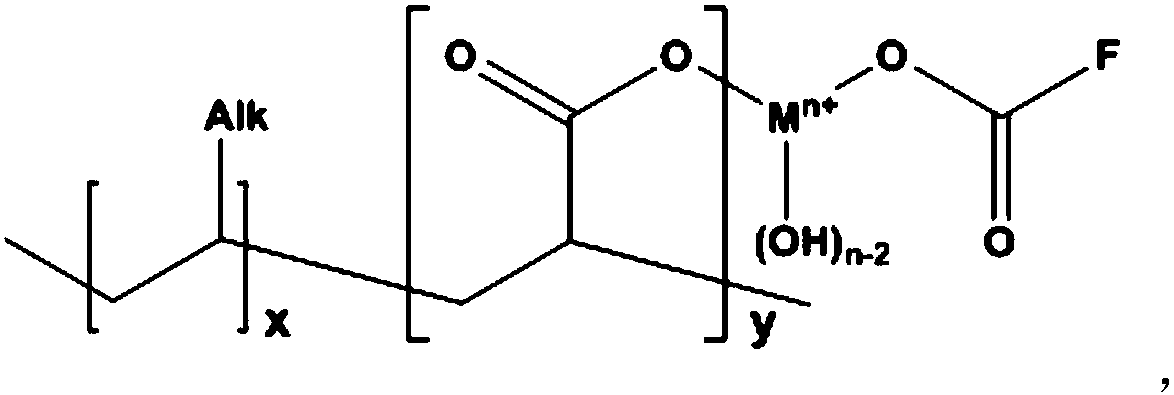

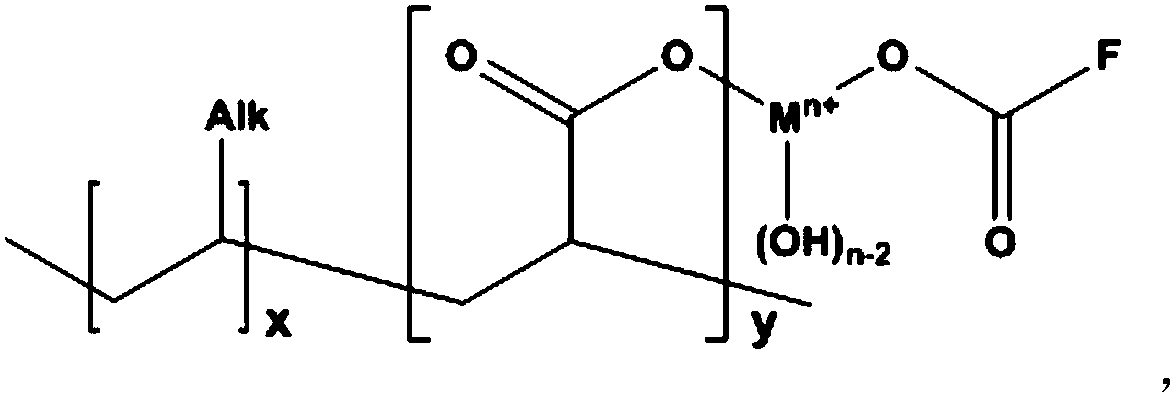

[0073] A kind of nano-additive, its chemical structural formula is:

[0074]

[0075] The preparation method of above-mentioned additive comprises the following steps:

[0076] (1) Add 1 L of distilled water and 5.69 g of solid sodium hydroxide (purity ≥ 97%, purchased from Aladdin) in a 2 L beaker. After the sodium hydroxide was completely dissolved, 28.05 g of levodopa (purity=99%, purchased from Aladdin) was added. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution A)

[0077] (2) Add 1 L of distilled water and 5.69 g of solid sodium hydroxide (purity>98.0% (GC) (T), purchased from TCI) into a 4 L beaker. After the sodium hydroxide was completely dissolved, 50 g of ethylene acrylic resin (Dow PRIMACOR 5980I, mass fraction of acrylic acid monomer 20.5%) was added. The above mixture was heated to 90 °C and stirred vigorously for 2 hours until the solution was completely transparent. (Solutio...

Embodiment 2

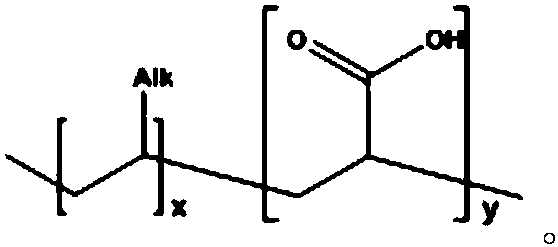

[0081] A kind of nano-additive, its chemical structural formula is:

[0082]

[0083] The preparation method of above-mentioned additive comprises the following steps:

[0084] (1) Add 1 L of distilled water and 5.69 g of solid sodium hydroxide (purity ≥ 97%, purchased from Aladdin) in a 2 L beaker. After the sodium hydroxide was completely dissolved, 42.74 g of 12-hydroxystearic acid (purity ≥ 80%, purchased from TCI) was added. The above mixture was heated to 90 °C and stirred vigorously for 1 hour until the solution was completely transparent. (Solution A)

[0085] (2) Add 1 L of distilled water and 5.69 g of solid sodium hydroxide (purity>98.0% (GC) (T), purchased from TCI) into a 4 L beaker. After the sodium hydroxide was completely dissolved, 50 g of ethylene acrylic resin (Dow PRIMACOR 5980I, mass fraction of acrylic acid monomer 20.5%) was added. The above mixture was heated to 90 °C and stirred vigorously for 2 hours until the solution was completely transparen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com