Piezoelectric composite component electrode manufacturing method

A technology of piezoelectric composites and components, applied in the manufacture/assembly of electrical components, piezoelectric/electrostrictive devices, piezoelectric/electrostrictive/magnetostrictive devices, etc., can solve polymer deformation and destroy piezoelectric Composite components, carbonization and other problems, to achieve the effect of strong weldability, high bonding strength and low electrode resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

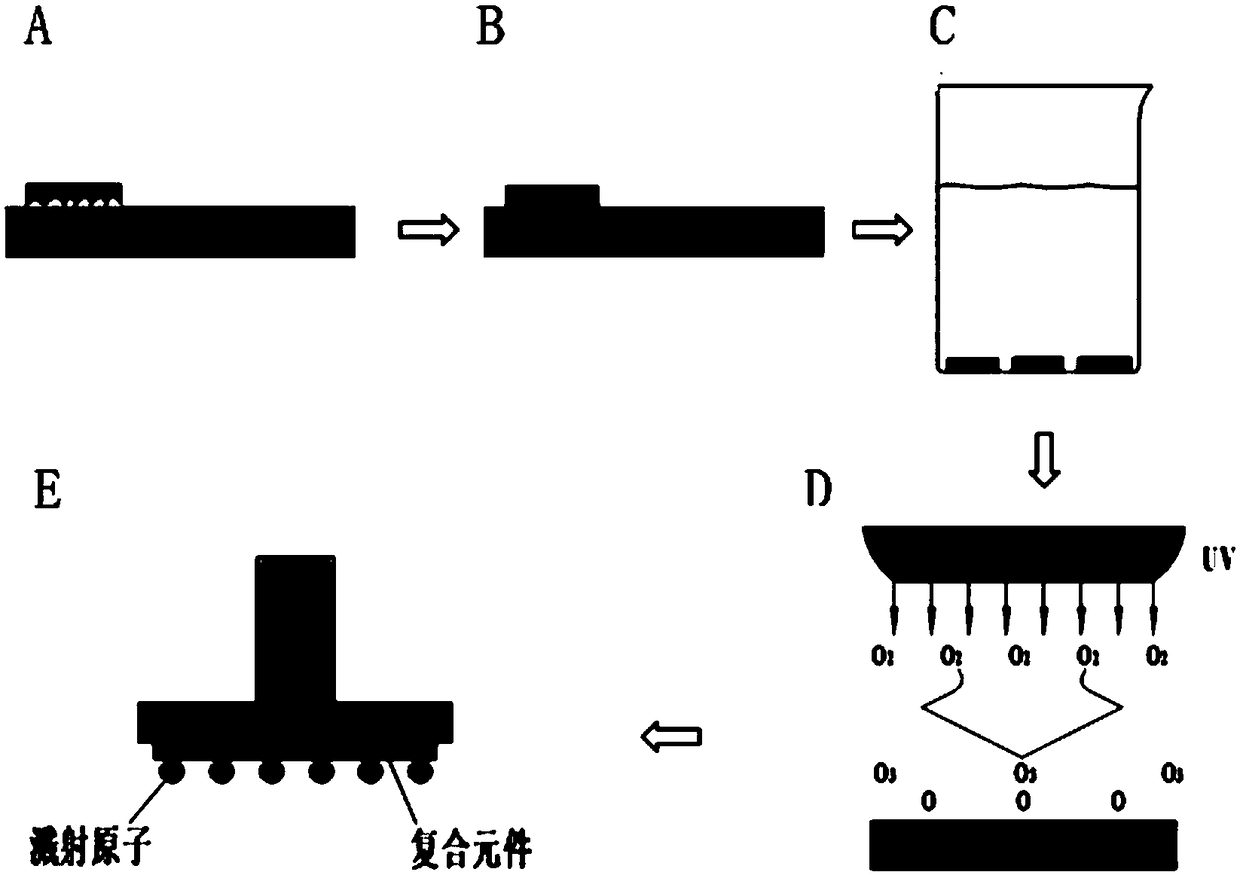

[0020] The specific implementation steps of embodiment 1 are as follows:

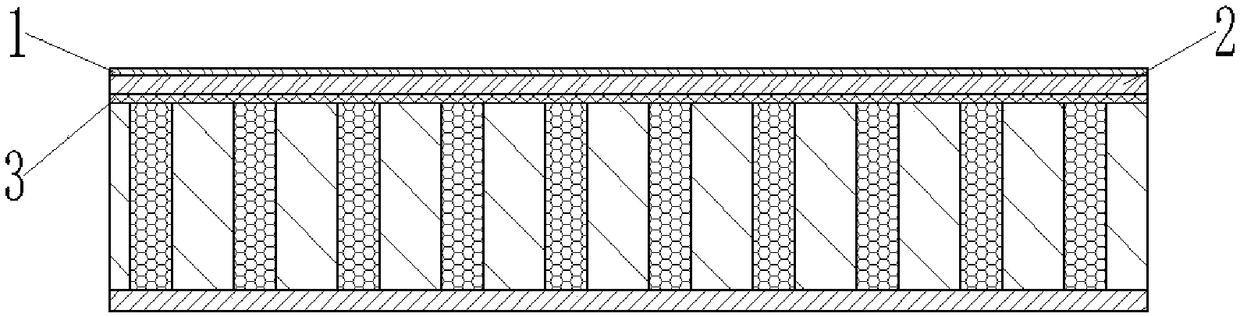

[0021] 1) Surface treatment of PZT piezoelectric composite components

[0022] The size of the PZT piezoelectric composite element in this embodiment is 10mm×10mm×3mm (length×width×thickness). Carry out in the following order: Grind it with an automatic pressure grinding and polishing machine, the rotation speed is 50rpm, and the grinding time is 40min, so that the surface flatness and roughness are lower than 1μm and 800nm respectively; PZT piezoelectric composite elements are put into Acetone, absolute ethanol, and deionized water were ultrasonically cleaned at room temperature for 20 minutes to remove dust and impurities attached to the surface; put in a degreasing solution at 40°C for 10 minutes to remove saponified oil and mineral oil on the surface; Dry in an oven at 60°C for 35 minutes;

[0023] 2) Surface modification of PZT piezoelectric composite elements

[0024] The surface of the PZT c...

Embodiment 2

[0027] In embodiment 2, the output power to the surface modification of PZT composite element in step 2) is 12mW / cm2, the ultraviolet irradiation time 5min; Step 3) in the sputtering Ti electrode layer time is 12min, sputtering Cu electrode layer time 40min, and the time for sputtering the Ag electrode layer was 15min; other conditions were the same as in Example 1.

Embodiment 3

[0028] In embodiment 3, the output power to the surface modification of PZT composite element in step 2) is 16mW / cm , the ultraviolet irradiation time 3min; Step 3) in the sputtering Ti electrode layer time is 15min, sputtering Cu electrode layer time 45min, and the time for sputtering the Ag electrode layer was 18min; other conditions were the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com