Method for inhibiting generation of lithium dendrite on surface of lithium metal

A lithium metal and lithium dendrite technology, applied in the field of electrode material processing, can solve problems such as irreversible loss of capacity, uneven deposition, battery short circuit, etc., and achieve the effects of improving volume utilization, prolonging battery life, and inhibiting lithium dendrites

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh the crystalline manganese nitrate-Mn(NO 3 ) 2 ·6H 2 O mass, and quickly transferred to a pre-dried weighing bottle. Above-mentioned weighing bottle is placed in glove box, in glove box, in above-mentioned weighing bottle, solution is added dropwise (solution is LiPF 6 Dissolved in an organic solvent, the organic solvent is EC / DEC (volume ratio = 1:1), and in the solution, LiPF 6 The concentration is 1M). After the manganese nitrate crystals are completely dissolved, molecular sieves are added to the weighing bottle to remove excess water to complete the configuration of the electrolyte, wherein the concentration of manganese ions is 0.05mol / L.

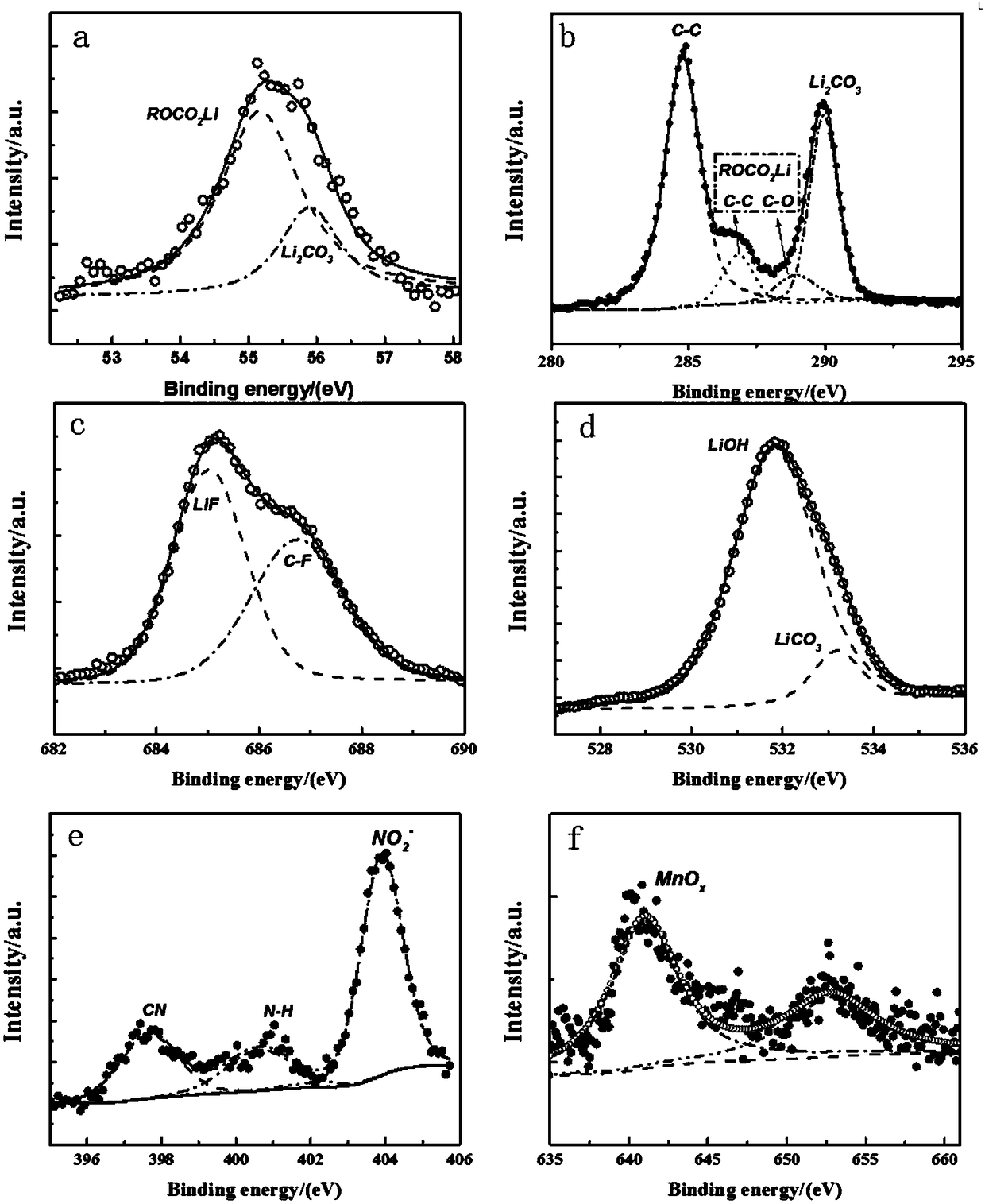

[0035] In the glove box, the lithium sheet is cut into a disc shape and compacted, and the lithium sheet with a smooth surface is immersed in the electrolyte of the above configuration. Wait for about 2 minutes, and after the surface of the lithium sheet is covered with a uniform black bright solid film, use DME solve...

Embodiment 2

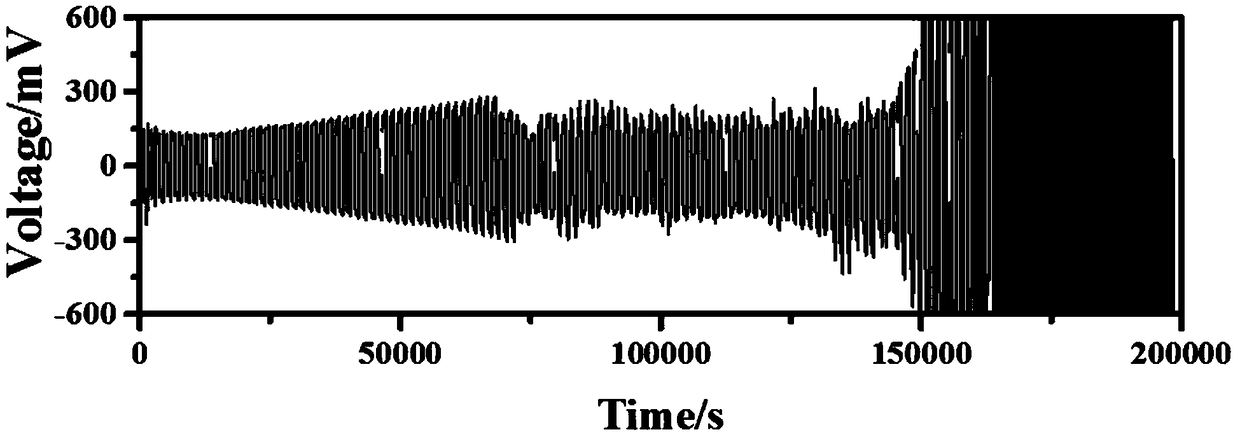

[0042] LiMn 2 o 4 , acetylene black, and PTFE are mixed and stirred evenly according to the mass ratio of 80:10:10, rolled evenly on a glass plate to form a film and cut into discs with a diameter of 12mm; ℃ in a vacuum drying oven and dried overnight to be the positive electrode material of the battery. The lithium metal was treated according to the method of Example 1, and the treated lithium sheet was used as the negative electrode of the battery. with LiPF 6 Solute dissolved in EC and DEC (volume ratio = 1:1) as electrolyte (1mol L -1 ), the glass fiber membrane was assembled into a half-cell as the separator, as the experimental group.

[0043] Using untreated lithium flakes as the negative electrode, the LiMn prepared by the above method 2 o 4 The electrode was positive and assembled into another half-cell as a control. The performance of the two sets of batteries was tested under the following test conditions: 2C current rate, 55°C, charge and discharge window 3....

Embodiment 3

[0047] Weigh the mass of crystalline manganese acetate on a balance and transfer quickly to a dry weighing bottle. Above-mentioned weighing bottle is placed in glove box, in glove box, in above-mentioned weighing bottle, solution is added dropwise (solution is LiPF 6 Dissolved in an organic solvent, the organic solvent is DMC / PC (volume ratio = 1:1), and in the solution, LiPF 6 The concentration is 1M). After the manganese acetate crystals are completely dissolved, molecular sieves are added to the weighing bottle to remove excess water to complete the configuration of the electrolyte, wherein the concentration of manganese ions is 0.01mol / L.

[0048] In the glove box, the lithium sheet is cut into a disc shape and compacted, and the lithium sheet with a smooth surface is immersed in the electrolyte of the above configuration. Wait for about 1 minute, and after the surface of the lithium sheet is covered with a uniform black bright solid film, use DME solvent to clean the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Current density | aaaaa | aaaaa |

| First cycle discharge capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com