Method for preparing carbon material with uniform pore sizes by block polymer as template

A technology of block polymers and carbon materials, which is applied in the preparation/purification of carbon compounds and carbon, chemical instruments and methods, etc., can solve the problems of uncontrollable morphological pore size, etc., achieve good electrochemical activity, and is suitable for large-scale industry. The effect of chemical production and uniform aperture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Weigh 750 mg of graphene oxide solid in a beaker, add 150 ml of deionized water, and prepare a 5 mg / ml graphene oxide dispersion, which is evenly dispersed by ultrasonic;

[0038] (2) Weigh 750 mg of block copolymer P123 solid in a beaker, add 150 ml of deionized water to prepare a 5 mg / ml aqueous solution of P123, and ultrasonically disperse it evenly;

[0039] (3) Mix the solution in step (1) and step (2) according to the mass ratio of graphene oxide and P123 (molecular weight 7000-12000) at 1:1 and ultrasonically disperse evenly;

[0040](4) Transfer the solution obtained in step (3) to a straight cylinder reaction tube with a filling height of 0.7, put it in a polytetrafluoroethylene-lined hydrothermal kettle, and react for 12 hours at a temperature of 180° C. The temperature should not exceed 160-220°C, and the reaction time should be controlled within 8-24h;

[0041] (5) vacuum-dry the black hydrogel obtained in step (4) at 60°C for 12 hours (drying temperatu...

Embodiment 2

[0052] [Differential weight gain method] After the cylindrical carbon is prepared with the mass ratio of P123 and GO as 1:1, weigh its mass as m 1 , then completely immerse the cylindrical carbon in the organic solvent, let it stand for 5 minutes, take it out, remove the residual organic solvent on the surface of the cylindrical carbon with clean filter paper, and weigh its mass as m 2 . The adsorption capacity is calculated according to the following formula:

[0053]

[0054] The cylindrical carbon prepared with the mass ratio of P123 and GO as 1:1, the adsorption capacity of toluene is 66.4g / g; the cylindrical carbon prepared with the mass ratio of P123 and GO as 1:4, the adsorption capacity of toluene 187.5g / g;

Embodiment 3

[0056] [UV Spectroscopy] After the mass ratio of P123 and GO is 1:1, the cylindrical carbon prepared is ground into powder, and 10 mg of sample powder is added to 50 ml of 200 mg / L methylene blue solution, stirred for 1 hour and then left to stand. Take the supernatant, and then detect it by UV spectrum to obtain the absorbance at 664nm, and obtain the concentration C after adsorption according to the standard curve obtained by the standard Lambert-Beer's law. 0 . The adsorption capacity is calculated according to the following formula:

[0057] M=(200-C 0 )×0.05

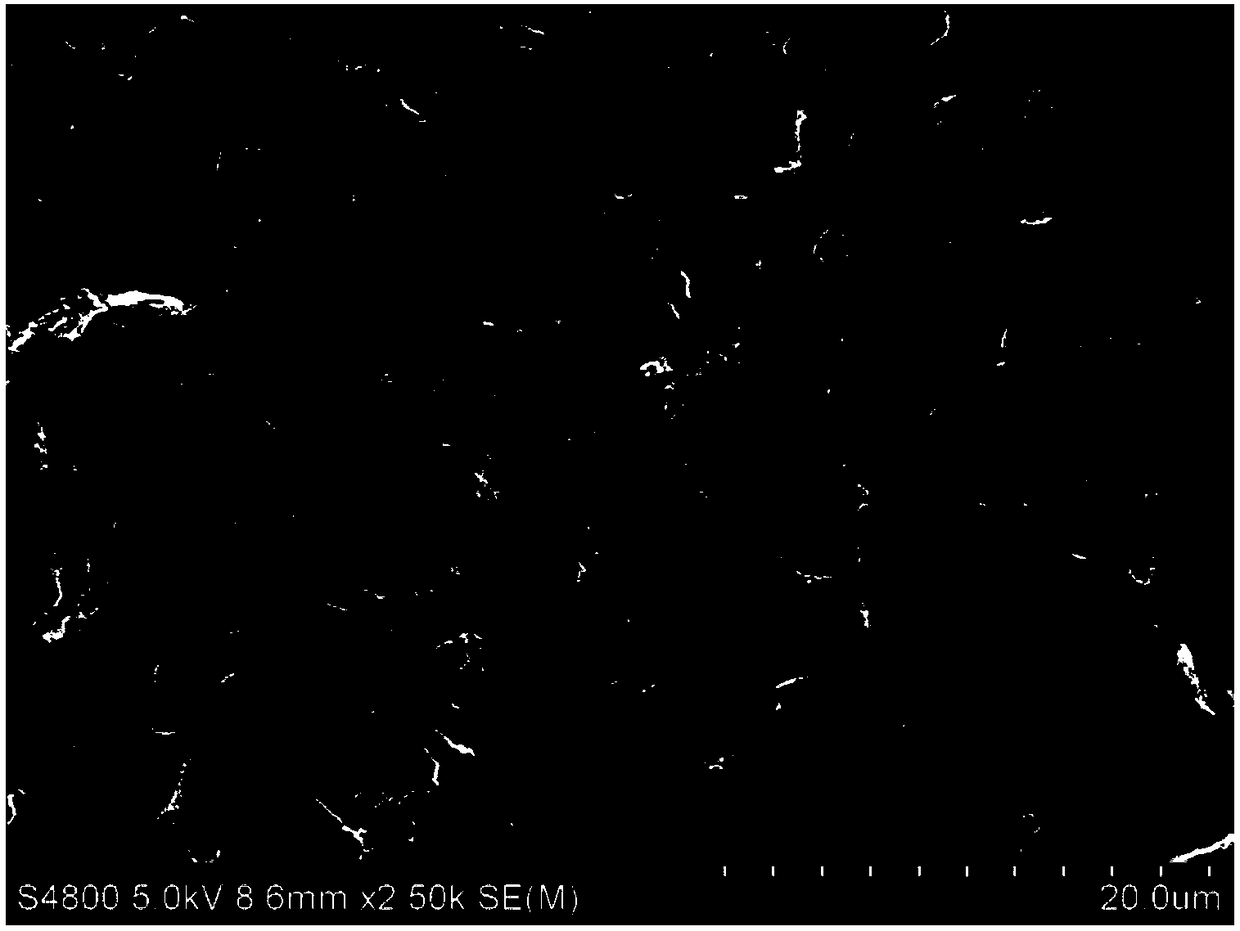

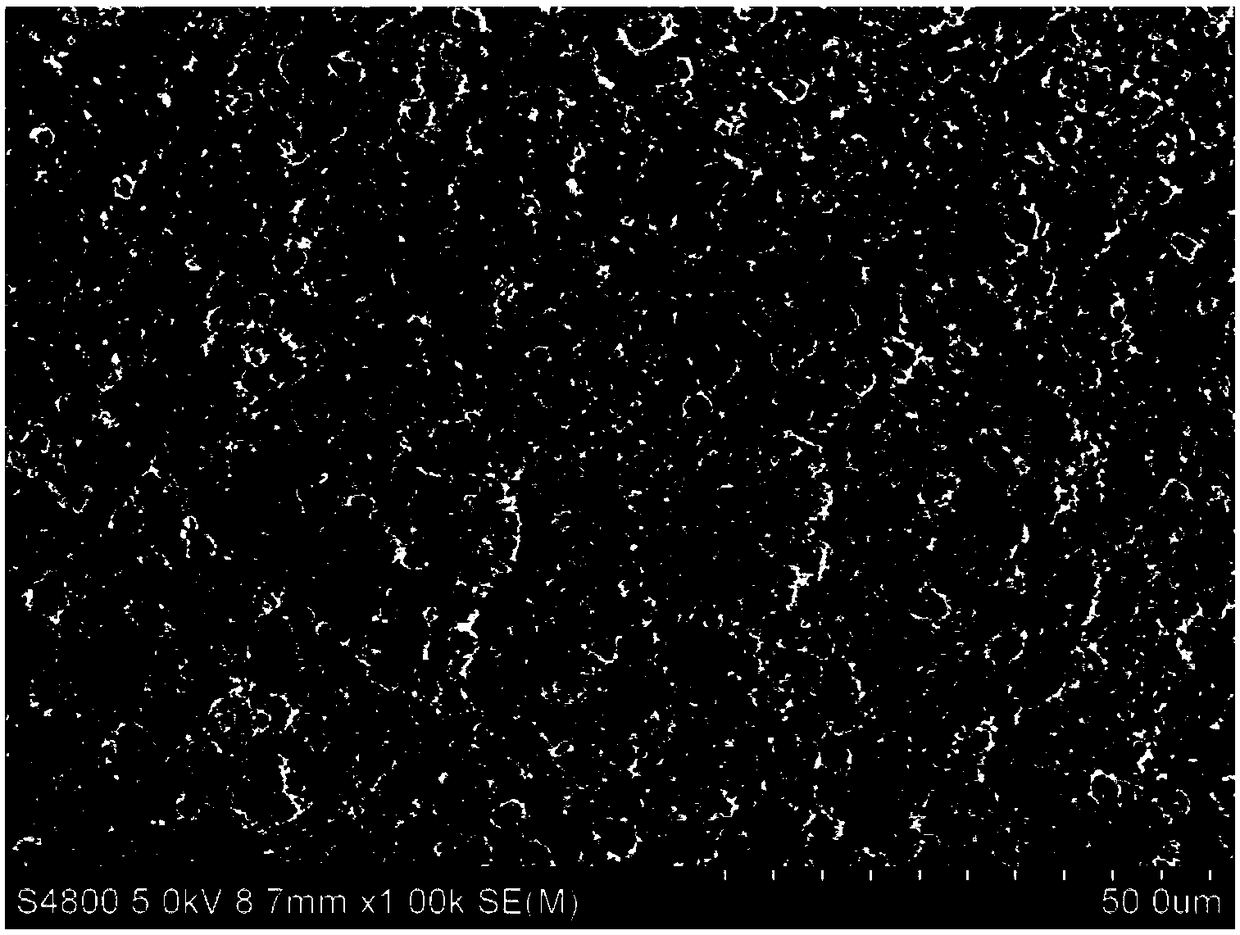

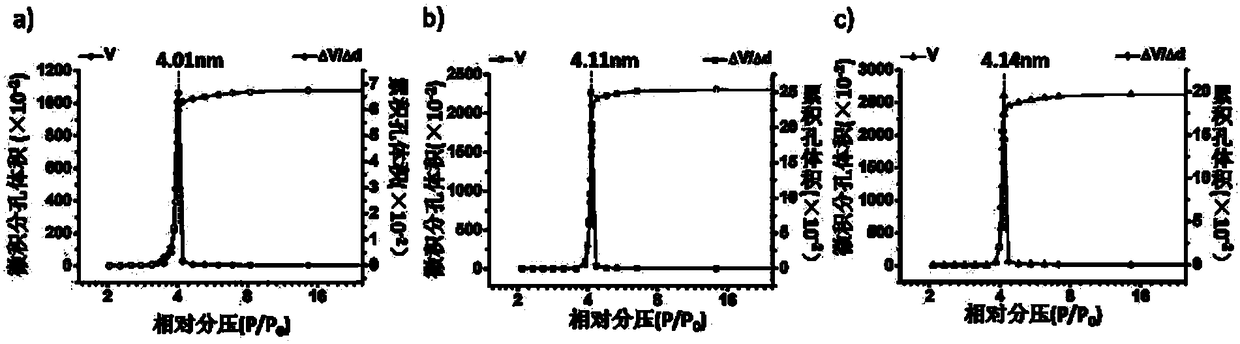

[0058] According to the above example, a porous carbon material with uniform pores can be prepared. Through the synergistic effect of the template effect of the soft template and the water removal effect of closed vacuum heating, the composite of polymer and graphene can be realized. By choosing different drying methods, dense carbon materials can be prepared. Graphene airgel, and the graphene composite disc obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com