Compound microbial liquid for treating anaerobic digested sludge and novel bioleaching method

A composite microbial bacteria and anaerobic digestion technology, which is applied in the field of processing anaerobic digested sludge composite microbial bacteria liquid and biological leaching, can solve the problems of rising and the deterioration of sludge dewatering effect, and achieves a simple process and reduces the actual operation operation. Difficulty, the effect of reducing the operating cost of bioleaching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] Bioleaching test of anaerobic digested sludge from a sewage treatment plant in Nanjing

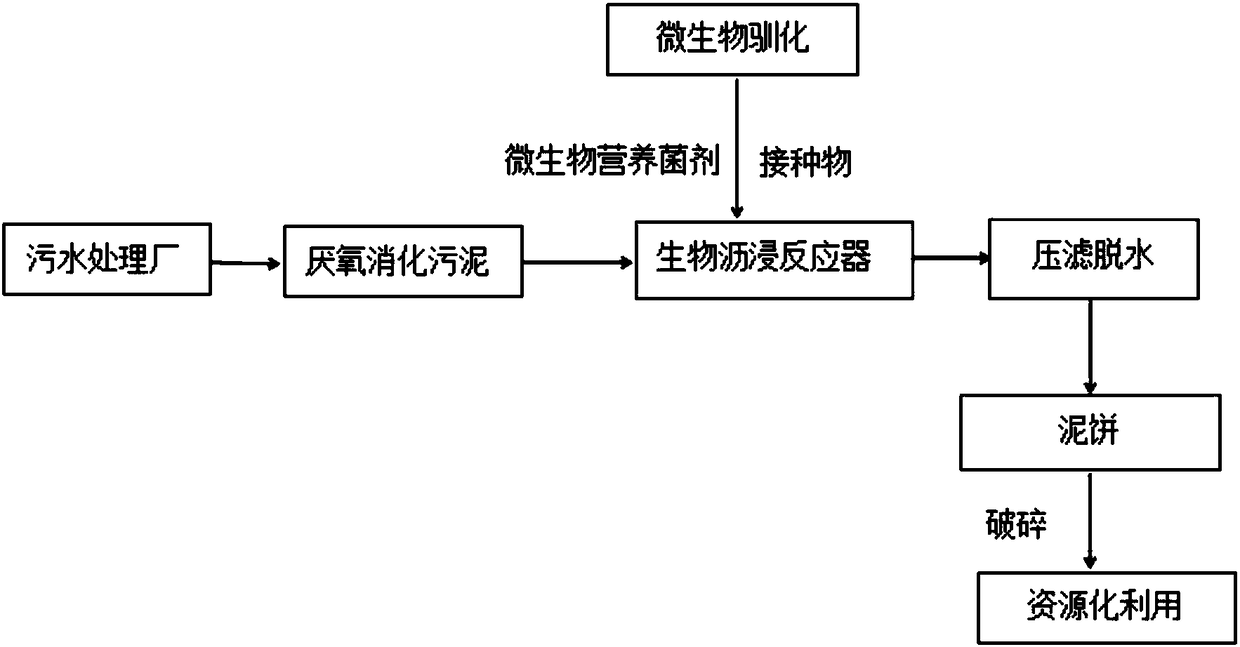

[0048] According to the technique mentioned in the present invention, according to flow process (see attached figure 1 ) to treat the anaerobic digestion sludge of the sewage treatment plant. Take about 20L of anaerobic digested sludge from the plant. The basic properties of the sludge are as follows: pH value is 7.10, solid content is 4.06%, organic matter is 48.9%, and sludge specific resistance is 6.8×10 13 m / kg, total nitrogen 35.1%, total phosphorus 27%.

[0049] (1) Using anaerobic digestion sludge to cultivate complex microbial flora

[0050] Thiobacillus ferrooxidans LX5 (A.ferrooxidans LX5, preservation number is CGMCC NO.0727), Thiobacillus thiooxidans TS6 (A.thiooxidans TS6, preservation number CGMCC NO.0759), Bordetella sp. ZW2 (Bordetella sp .preservation number CGMCC NO.3033), Pichia pastoris D13 (P.spartinae D13, preservation number CGMCC NO.3035) were inoculated i...

Embodiment 2

[0068] Bioleaching test of anaerobic digested sludge from a sewage treatment plant in Wuxi

[0069] According to the technique mentioned in the present invention, according to flow process (see attached figure 1 ) to treat the anaerobic digestion sludge of the sewage treatment plant. Take about 100L of anaerobic digested sludge from the plant. The basic properties of the sludge are as follows: pH value is 7.56, solid content is 3.0%, organic matter is 50.1%, and the specific resistance of sludge is 8.37×10 13 m / kg, total nitrogen 35.1%, total phosphorus 27%.

[0070] (1) Using anaerobic digestion sludge to cultivate complex microbial flora

[0071] Inoculate Thiobacillus ferrooxidans LX5, Thiobacillus thiooxidans TS6, Bordetella ZW2, and Pichia pastoris D13 into their respective culture media (Thiobacillus ferrooxidans LX5 medium g / L: (NH 4 ) 2 SO 4 3.5, KCl 0.119, K 2 HPO 4 0.58, Ca(NO 3 ) 2 4H 2 O 0.168, MgSO 4 ·7H 2 O 4.42 with 10N H 2 SO 4 Adjust pH to 2.5;...

Embodiment 3

[0077] Bioleaching test of anaerobic digested sludge from a sewage treatment plant in Zhengzhou

[0078] According to the technique mentioned in the present invention, according to flow process (see attached figure 1 ) to treat the anaerobic digestion sludge of the sewage treatment plant. About 500L of anaerobic digested sludge from the plant was taken, and the basic properties of the sludge were determined as follows: the pH value is 7.32, the solid content is 3.6%, the organic matter is 48.6%, and the specific resistance of the sludge is 6.37×10 13 m / kg, total nitrogen 33.1%, total phosphorus 25%.

[0079] (1) Using anaerobic digestion sludge to cultivate complex microbial flora

[0080] Inoculate Thiobacillus ferrooxidans LX5, Thiobacillus thiooxidans TS6, Bordetella ZW2, and Pichia pastoris D13 into their respective culture media (Thiobacillus ferrooxidans LX5 medium g / L: (NH 4 ) 2 SO 4 3.5, KCl 0.119, K 2 HPO 4 0.58, Ca(NO 3 ) 2 4H 2 O 0.168, MgSO 4 ·7H 2 O ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com