Boehmite covered graphite composite negative electrode material as well as preparation method and application thereof

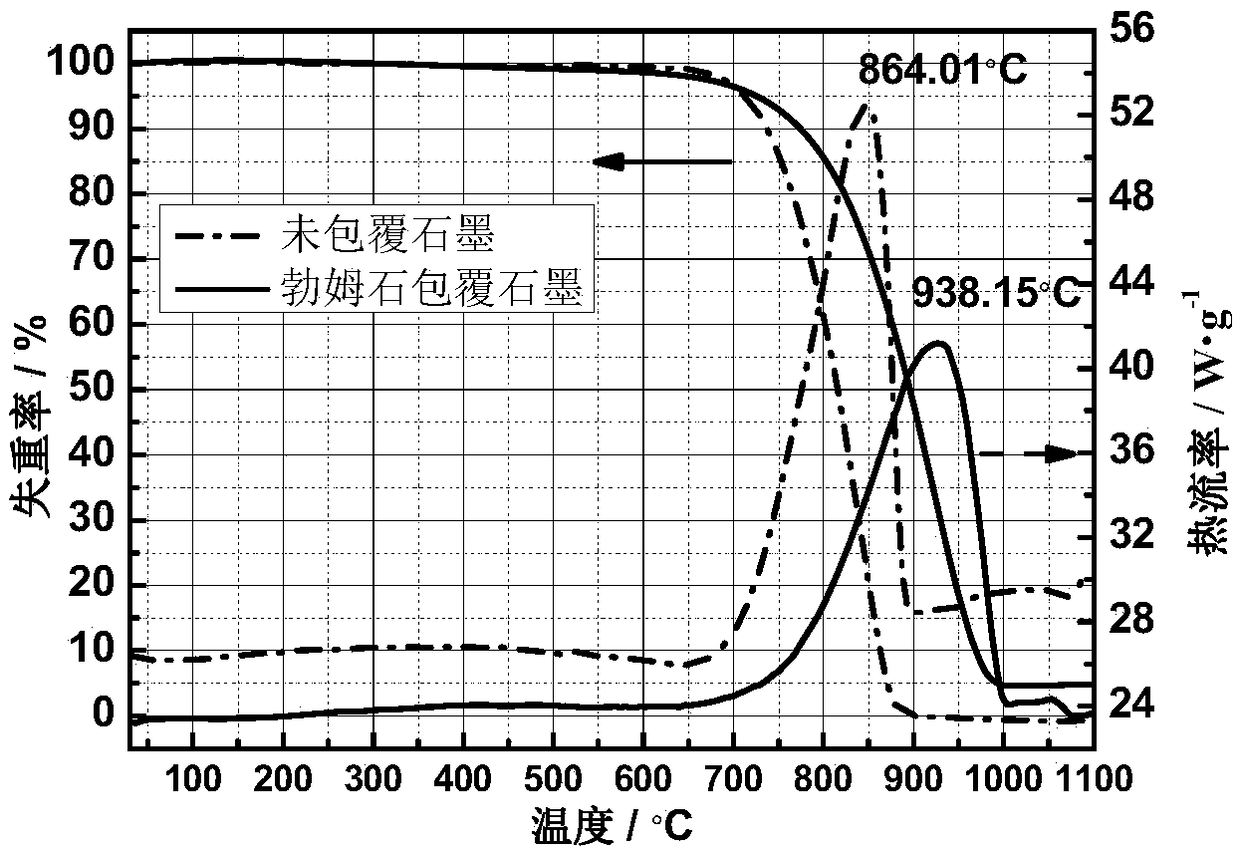

A negative electrode material, boehmite technology, applied in the field of boehmite-coated graphite composite negative electrode materials, can solve the problems of low contact resistance, poor thermal stability, fire or explosion of the negative electrode sheet, and achieve low rebound rate of the electrode sheet, Improved thermal stability, high vibration and compacted density effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0076](1) Take graphite and boehmite solution respectively according to the mass ratio of boehmite solute in graphite and boehmite solution 98:2 (in the boehmite solution, the mass percentage of boehmite solute is 5% ), get the above-mentioned quantitative boehmite solution and add it to a certain proportion of deionized water, mix evenly and then add graphite according to the mass ratio to form a suspension, the solid content of the suspension is 30%.

[0077] (2) After that, centrifugal spray drying is carried out under the condition that the outlet temperature is 110°C. The dried sample is directly sieved to obtain the boehmite-coated graphite composite negative electrode material.

Embodiment 2

[0079] (1) According to the mass ratio of boehmite solute and CMC in graphite and boehmite solution to 98:2:(0.1-2), weigh graphite and boehmite solution respectively (in boehmite solution, boehmite solute The mass percent content is 15%) and CMC, take the above-mentioned quantitative CMC powder and add it to a certain proportion of deionized water and stir, and then add the boehmite solution according to the mass ratio after completely dissolving and continue stirring for a period of time. After stirring evenly, press The mass ratio is made by adding graphite to form a suspension, and the solid content of the suspension is 40%.

[0080] (2) After that, centrifugal spray drying is carried out under the condition that the outlet temperature is 110°C.

[0081] (3) Put the dried sample into a tunnel kiln at 900°C for high-temperature treatment, take out the processed sample, and pass through a 250-mesh screen to obtain a boehmite-coated graphite composite negative electrode mater...

Embodiment 3

[0083] (1) Take graphite and boehmite solution respectively according to the mass ratio of boehmite solute and CMC in graphite and boehmite solution (in boehmite solution, The mass percent composition of boehmite solute is 25%) and CMC, get the above-mentioned quantitative CMC powder and join in a certain proportion of deionized water and stir, after dissolving completely, add boehmite solution by mass ratio and continue to stir for a period of time, After uniform stirring, graphite is added according to the mass ratio to form a suspension, and the solid content of the suspension is 45%.

[0084] (2) Spray drying is carried out under the condition that the outlet temperature is 110° C. in the two-fluid spray drying tower. The dried sample was directly sieved to obtain boehmite-coated graphite A.

[0085] (3) Repeat the above steps (1) and (2) to obtain boehmite-coated graphite B with a coating amount of 2%.

[0086] (4) Put the boehmite-coated graphite B into a box-type carb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com