Method for separating dimension of graphene oxide

A graphene, size technology, applied in chemical instruments and methods, inorganic chemistry, carbon compounds, etc., can solve problems such as can not be effectively avoided

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] Preparation of Graphene Oxide

[0061] 1. Pre-oxidized graphite

[0062] Weigh 2.5g of phosphorus pentoxide and 2.5g of potassium persulfate, and add them into a 250mL Erlenmeyer flask. Add 20mL of concentrated sulfuric acid under constant stirring, heat to 80°C, slowly add 3g of graphite powder to the solution, keep the temperature of the solution at 80°C for 4.5h, then cool to room temperature. Then slowly add deionized water. During this process, ensure that the temperature of the solution does not exceed 80°C. The mixture is allowed to stand overnight, filtered to remove excess concentrated sulfuric acid, and dried at 60°C.

[0063] 2. Preparation of Graphite Oxide

[0064] Add the dried pre-oxidized graphite into 120mL of concentrated sulfuric acid, and slowly add 15g of potassium permanganate while stirring continuously. This process is carried out in an ice bath, and the temperature of the whole process is guaranteed to be below 80°C, and the stirring is contin...

Embodiment 2

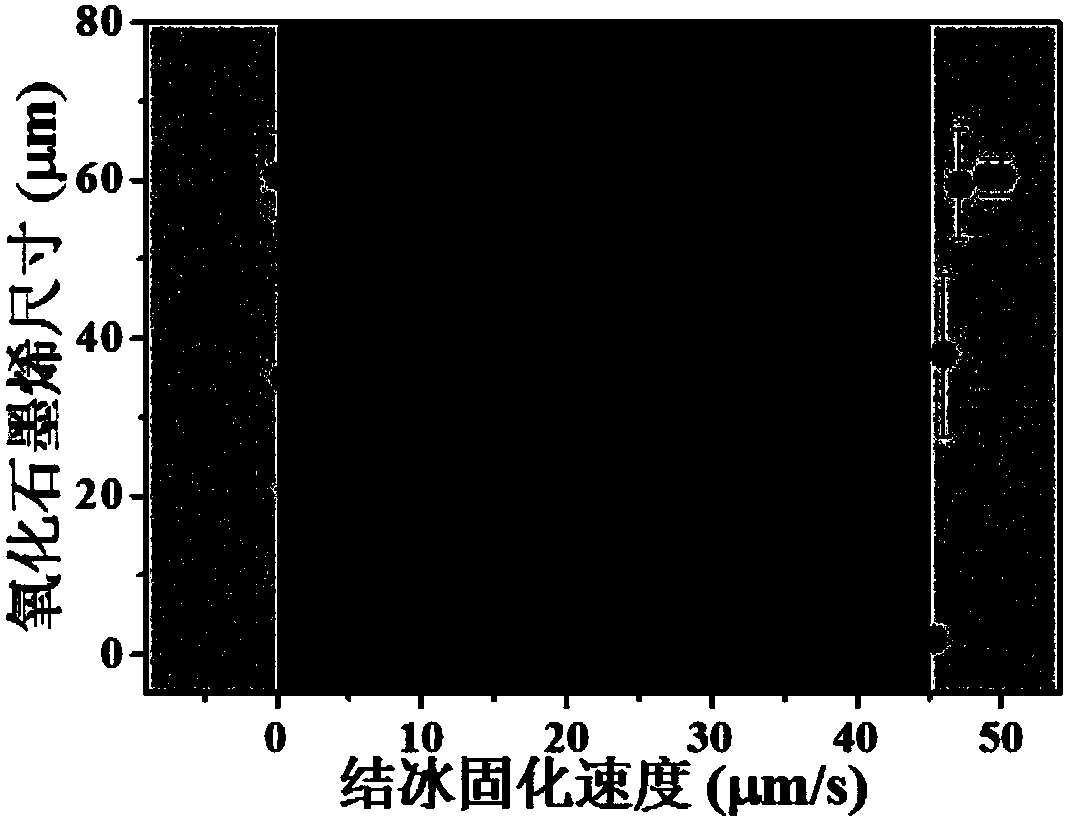

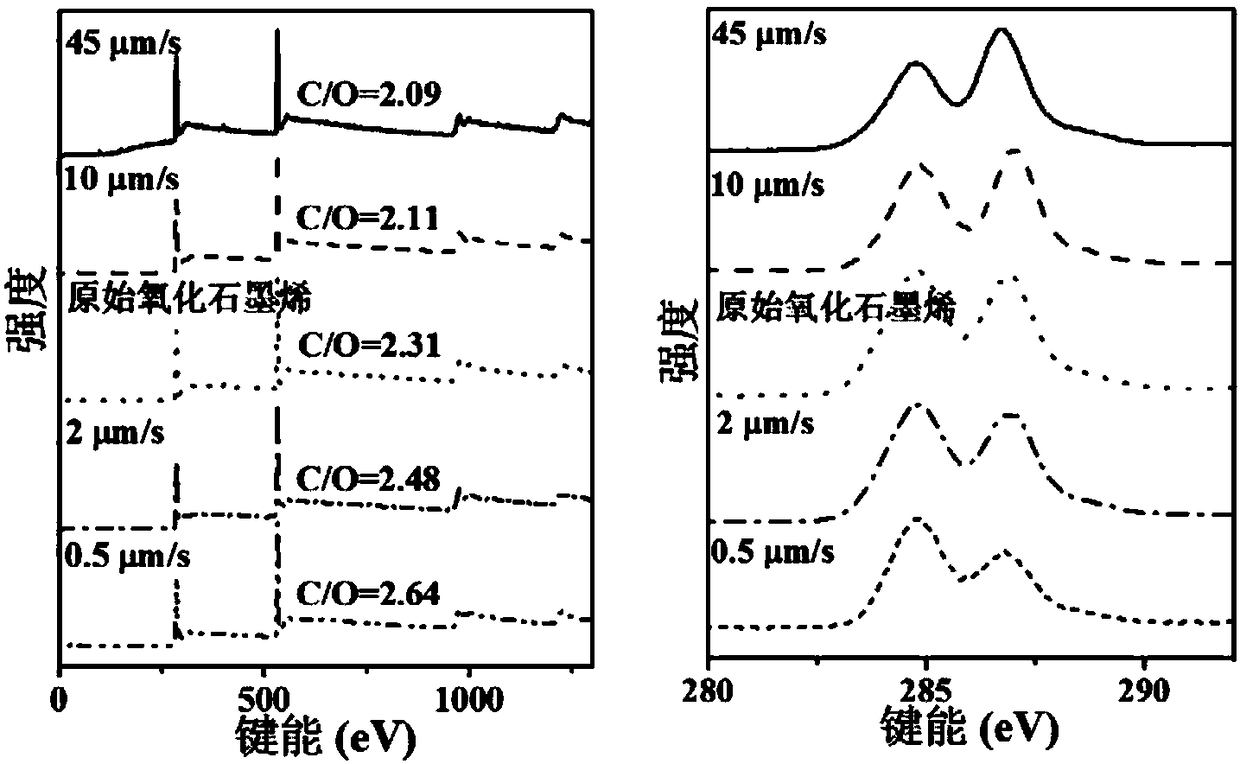

[0070] Size separation of graphene oxide

[0071] 1. Stir and disperse the graphene oxide prepared in Example 1 into deionized water to obtain a uniform and stable 0.1 mg / ml graphene oxide aqueous dispersion.

[0072] 2. Transfer the above-mentioned uniform and stable graphene oxide aqueous dispersion into a sealed plastic tube, and the liquid surface of the graphene oxide aqueous dispersion is at a certain distance from the mouth of the tube. The plastic centrifuge tube is 4cm long and 2cm in diameter.

[0073] 3. Equilibrate the above aqueous dispersion of graphene oxide that needs to be separated at 25° C. for 30 minutes.

[0074] 4. Fill liquid nitrogen into a plastic petri dish with a diameter of 10 cm, and place the plastic petri dish containing liquid nitrogen above the plastic tube containing the graphene oxide aqueous dispersion.

[0075] 5. Control the freezing and solidification speed of the graphene oxide aqueous dispersion by adjusting the distance between the g...

Embodiment 3

[0080] Printing preparation of graphene conductive wires

[0081] The graphene oxide dry powders in various size ranges after freeze-drying in Example 2 were dispersed into deionized water to prepare dispersions with a concentration of 20 mg / ml.

[0082] 1. Put these high-viscosity graphene oxide aqueous dispersions into the dispenser syringe (3cm 3 ), sealed with a needle with an inner diameter of 200 μm.

[0083]2. Use an air pressure pump (Ultimus Ⅰ, EFD, Inc) to provide a suitable pressure to pump out the water-based graphene oxide ink, and form regular and orderly lines according to the preset procedure.

[0084] 3. Place the printed graphene oxide wire in a dry environment and dry it at 60°C for 12 hours.

[0085] 4. Transfer the dried graphene oxide thread to a closed glass bottle, and add 3-5 drops of HI (40%) aqueous solution to the glass bottle, and let it stand for 12 hours under dark conditions.

[0086] 5. Take out the graphene oxide conductive wire after chemi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com