Nanosized ferrite composite material with double-shell structure and preparation method of nanosized ferrite composite material

A nano-ferrite and composite material technology is applied in the field of nano-ferrite composite material and its preparation, and can solve the problems of low specific surface area, poor chemical stability of spinel-type ferrite nanoparticles, easy agglomeration and the like , to achieve the effect of increasing specific surface area, improving chemical stability and avoiding agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

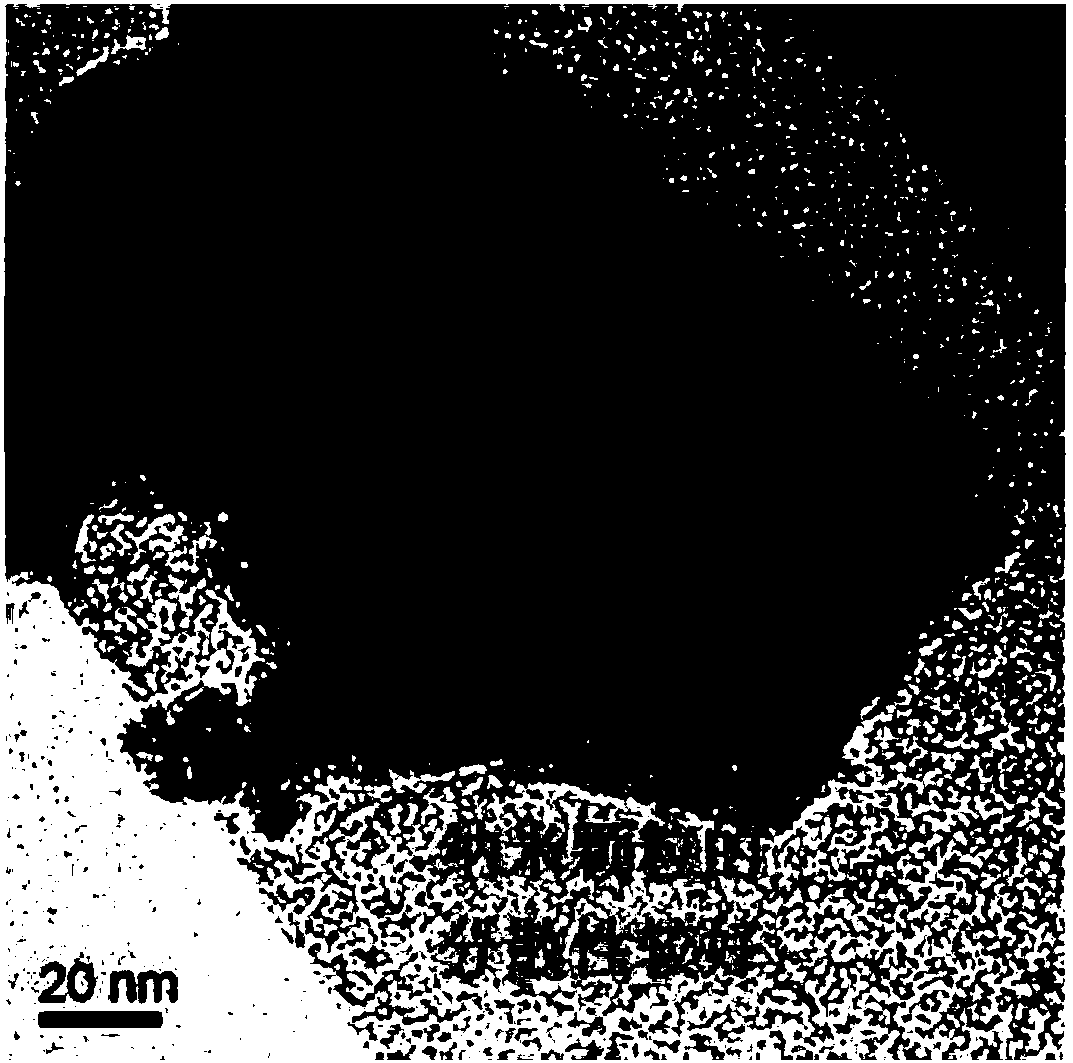

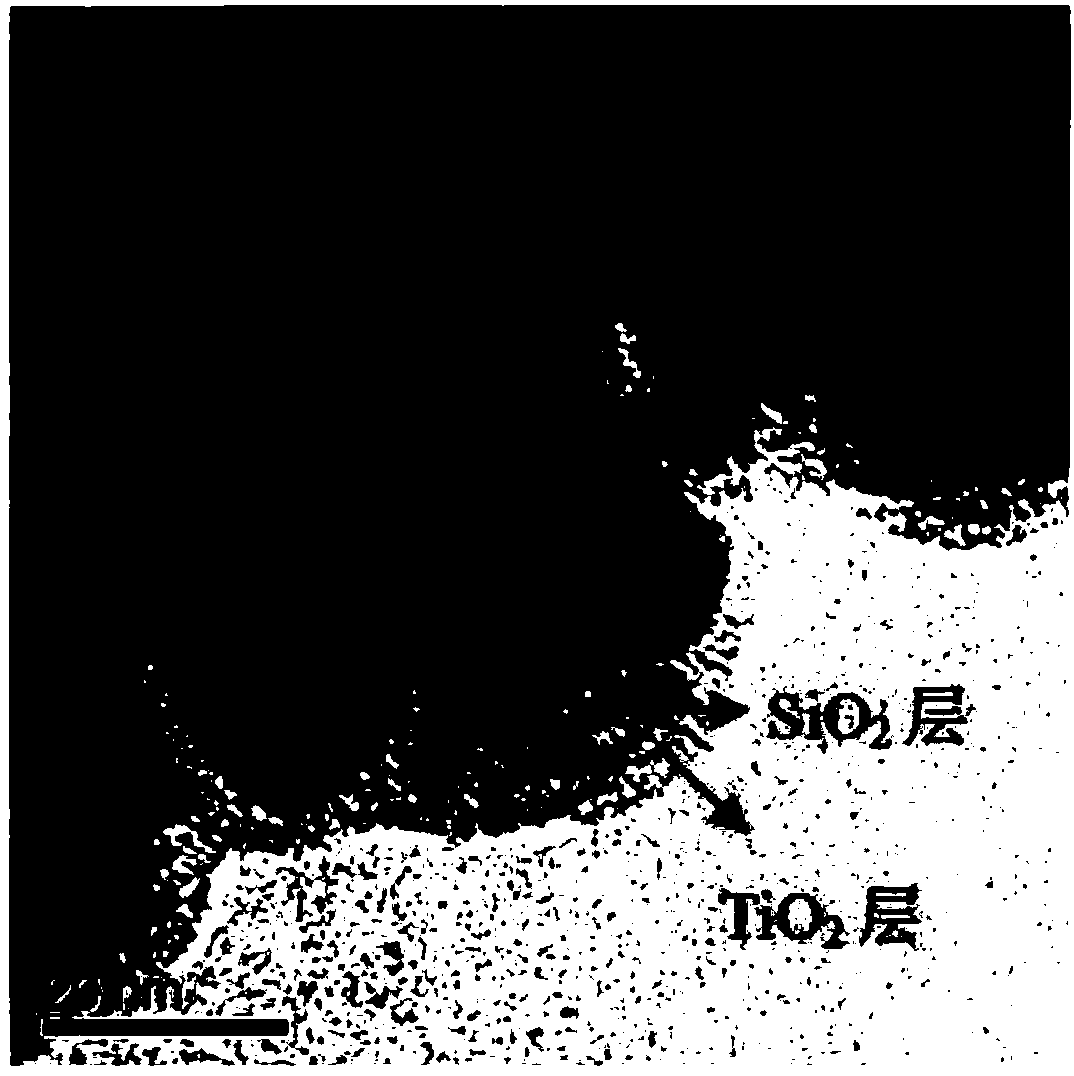

[0061] Described a kind of double-shell structure nano-ferrite composite material (using NiFe 2 o 4 The preparation method for nucleus) comprises the steps:

[0062] (1) 10.4992g Fe(NO 3 ) 3 9H 2 O and 3.7980gNi(NO 3 ) 2 ·6H 2 O was dissolved in 250ml ethanol and stirred for 2-3h to obtain a transparent solution; 8.0689g citric acid was dissolved in 250ml ethanol and stirred for 2-3h to obtain a transparent solution. Under vigorous stirring, the citric acid-ethanol solution is added to the mixed metal nitrate-ethanol solution under stirring, and the stirring is continued for 4 hours to obtain a complex metal nitrate-citric acid ethanol solution;

[0063] (2) Under vigorous stirring, the pH value of the complex metal nitrate-citric acid ethanol solution obtained in step (1) is adjusted to 4.0 with a concentration of 1.5mol / L ammonia, and the stirring is continued for 24h to form a complex transition metal hydrogen oxide suspension;

[0064] (3) Add about 40 g of absorb...

Embodiment 2

[0074] Described a kind of double-shell structure nano-ferrite composite material (with Ni 0.6 Zn 0.4 Fe 2 o 4 The preparation method for nucleus) comprises the steps:

[0075] (1) 10.3808g Fe(NO 3 ) 3 9H 2 O and 2.2531g Ni(NO 3 ) 2 ·6H 2 O, 1.5210g Zn(NO 3 ) 2 ·6H 2 O was dissolved in 250ml ethanol and stirred for 2-3h to obtain a transparent solution; 7.9774g citric acid was dissolved in 250ml ethanol and stirred for 2-3h to obtain a transparent solution. Under vigorous stirring, the citric acid-ethanol solution is added to the mixed metal nitrate-ethanol solution under stirring, and the stirring is continued for 4 hours to obtain a complex metal nitrate-citric acid ethanol solution;

[0076] (2) Under vigorous stirring, adjust the pH value of the complex metal nitrate-citric acid ethanol solution obtained in step (1) to 4.0 with a concentration of 0.5mol / L ammonia, and continue to stir for 24h to form complex transition metal hydrogen oxide suspension;

[0077...

Embodiment 3

[0087] Described a kind of double-shell structure nano-ferrite composite material (with CoFe 2 o 4 The preparation method for nucleus) comprises the steps:

[0088] (1) 10.4885g Fe(NO 3 ) 3 9H 2 O and 3.7587g Co(NO 3 ) 2 ·6H 2 O was dissolved in 250mL ethanol and stirred for 2-3h to obtain a transparent solution; 8.0606g citric acid was dissolved in 250mL ethanol and stirred for 2-3h to obtain a transparent solution. Under vigorous stirring, the citric acid-ethanol solution is added to the mixed metal nitrate-ethanol solution under stirring, and the stirring is continued for 4 hours to obtain a complex metal nitrate-citric acid ethanol solution;

[0089] (2) Under vigorous stirring, the pH value of the complex metal nitrate-citric acid ethanol solution obtained in step (1) is adjusted to 5.0 with a concentration of 1.0mol / L ammonia, and the stirring is continued for 24h to form a complex transition metal hydrogen oxide suspension;

[0090] (3) Add about 40 g of absorb...

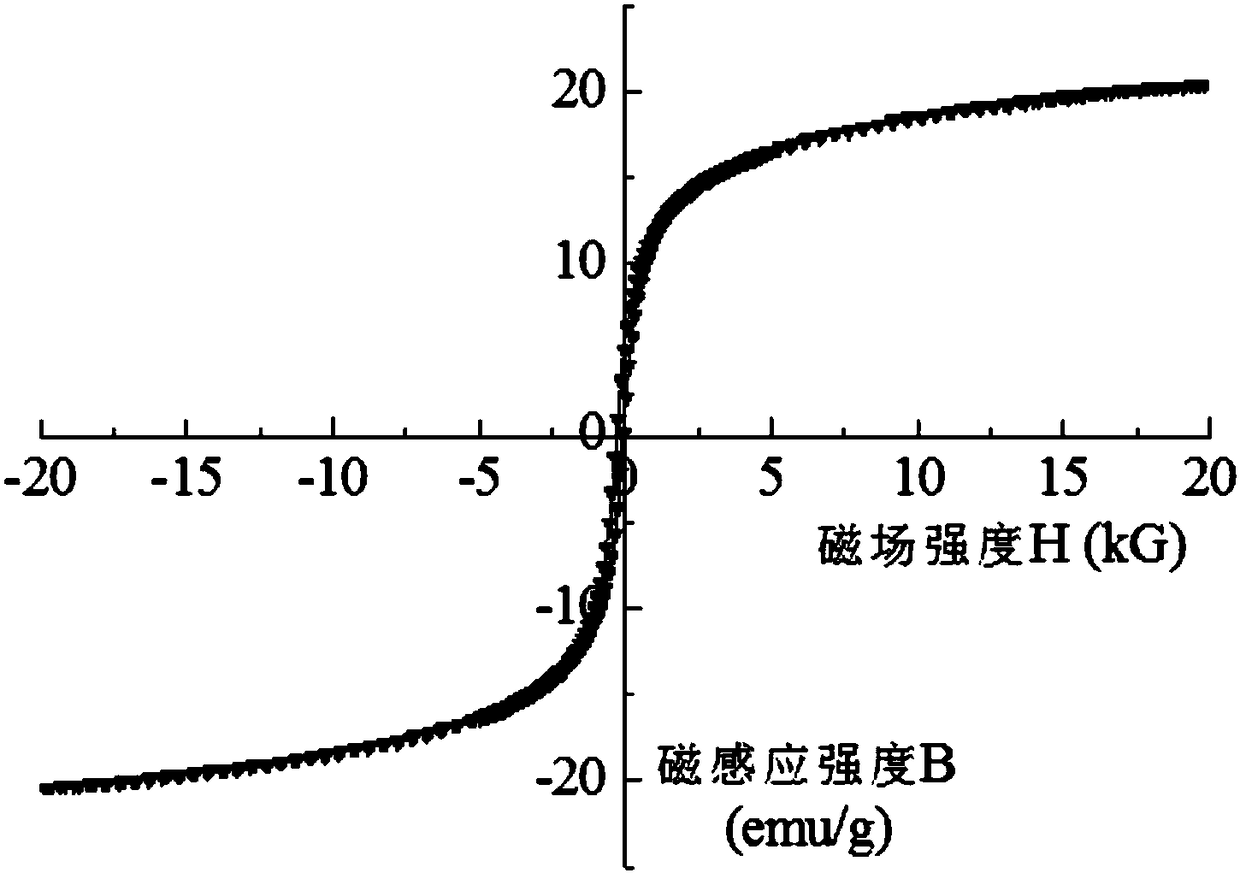

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Saturation magnetization | aaaaa | aaaaa |

| Coercivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com