Preparation method of toughened antimicrobial mulberry fiber

A mulberry fiber and toughening technology, which is applied in the field of preparation of toughened antibacterial mulberry fiber, can solve the problems of poor antibacterial performance, damage to the structure of mulberry fiber, and poor fiber toughness, so as to reduce short fibers and improve fracture Energy, toughness improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

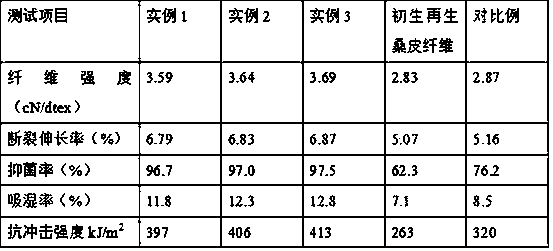

Examples

example 1

[0025] Take 100g of mulberry bark and soak it in 400mL sulfuric acid solution with a mass fraction of 30%. , heat up to 90°C, add 100mL sodium hydroxide solution with a mass fraction of 40%, 50mL sodium polyphosphate solution with a mass fraction of 4%, and 30mL sodium silicate solution with a mass fraction of 6% into the water bath. After cooking for 2 hours, filter and remove the filtrate to obtain alkali-boiled mulberry bark; soak the above-mentioned alkali-boiled mulberry bark with 150 mL of 10% hydrochloric acid for 8 minutes, take out the soaked mulberry bark and beat it with a wooden hammer for 30 minutes, and rinse it with water for 3 times Then put it into an oven, heat up to 100°C, and dry for 10 hours to obtain degummed mulberry fiber; prepare an aqueous solution of N-methylmorpholine with a mass fraction of 30%, and mix the aqueous solution of N-methylmorpholine and the degummed mulberry fiber by Mix at a mass ratio of 15:1 to obtain 230mL of mixed solution, put th...

example 2

[0027]Take 110g of mulberry bark and soak it in 425mL sulfuric acid solution with a mass fraction of 30%. In the pot, heat up to 95°C, add 110mL of sodium hydroxide solution with a mass fraction of 40%, 55mL of a sodium polyphosphate solution with a mass fraction of 4%, and 35mL of a sodium silicate solution with a mass fraction of 6% , after cooking for 2.5 hours, filter, remove the filtrate to obtain alkali-boiled mulberry bark; soak the above-mentioned alkali-boiled mulberry bark with 175 mL of 10% hydrochloric acid for 9 minutes, take out the soaked mulberry bark and beat it with a wooden hammer for 32 minutes, and rinse with water Put it into an oven after 4 times, heat up to 105°C, and dry for 11 hours to obtain degummed mulberry fiber; prepare an aqueous solution of N-methylmorpholine with a mass fraction of 30%, and mix the aqueous solution of N-methylmorpholine with degummed mulberry The fibers were mixed according to the mass ratio of 15:1 to obtain 240mL of the mixe...

example 3

[0029] Take 120g of mulberry bark and soak it in 450mL sulfuric acid solution with a mass fraction of 30%. , heat up to 100°C, add 120mL sodium hydroxide solution with a mass fraction of 40%, 60mL sodium polyphosphate solution with a mass fraction of 4%, and 40mL sodium silicate solution with a mass fraction of 6% into the water bath. After cooking for 3 hours, filter and remove the filtrate to obtain the alkali-boiled mulberry bark; soak the above-mentioned alkali-boiled mulberry bark with 180 mL of hydrochloric acid with a mass fraction of 10% for 10 minutes, take out the soaked mulberry bark and beat it with a wooden hammer for 35 minutes, and rinse it with water for 5 times Then put it into an oven, heat up to 110°C, and dry for 12 hours to obtain degummed mulberry fiber; prepare an aqueous solution of N-methylmorpholine with a mass fraction of 30%, and mix the aqueous solution of N-methylmorpholine and the degummed mulberry fiber by Mix at a mass ratio of 15:1 to obtain 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com