Method for preparing porous carbon material by utilizing water hyacinth, and application

A technology of porous carbon materials and water hyacinth, applied in chemical instruments and methods, carbon compounds, water/sewage treatment, etc., can solve the problems of water body anaerobic environment, low value-added utilization, high salvage cost, etc., and achieve large specific surface area , the effect of rich pore structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] A kind of method utilizing water hyacinth to prepare porous carbon material, comprises the following steps:

[0030] (1) Pretreatment of water hyacinth: take the stem of water hyacinth, wash it, and air-dry it naturally for 5-6 days, then dry it in an oven at 105°C for 24 hours, then crush the dried stem of water hyacinth with a pulverizer, and dry it for 40 Mesh sieve;

[0031] (2) Hydrothermal treatment: Weigh 6.0 g of water hyacinth powder in step (1), add 60 mL of deionized water into a hydrothermal reaction kettle, and mix well; then place the reaction kettle at a temperature of 200° C. After the reaction, filter and dry to obtain lignite-like biomass hydrothermal carbon;

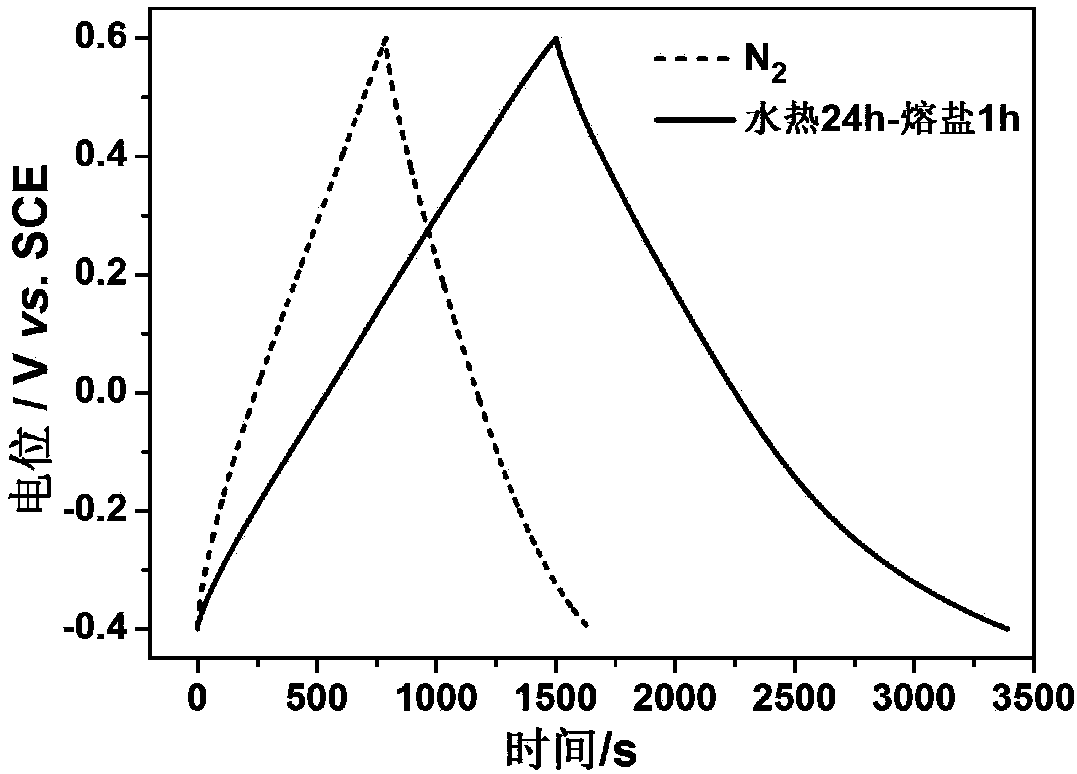

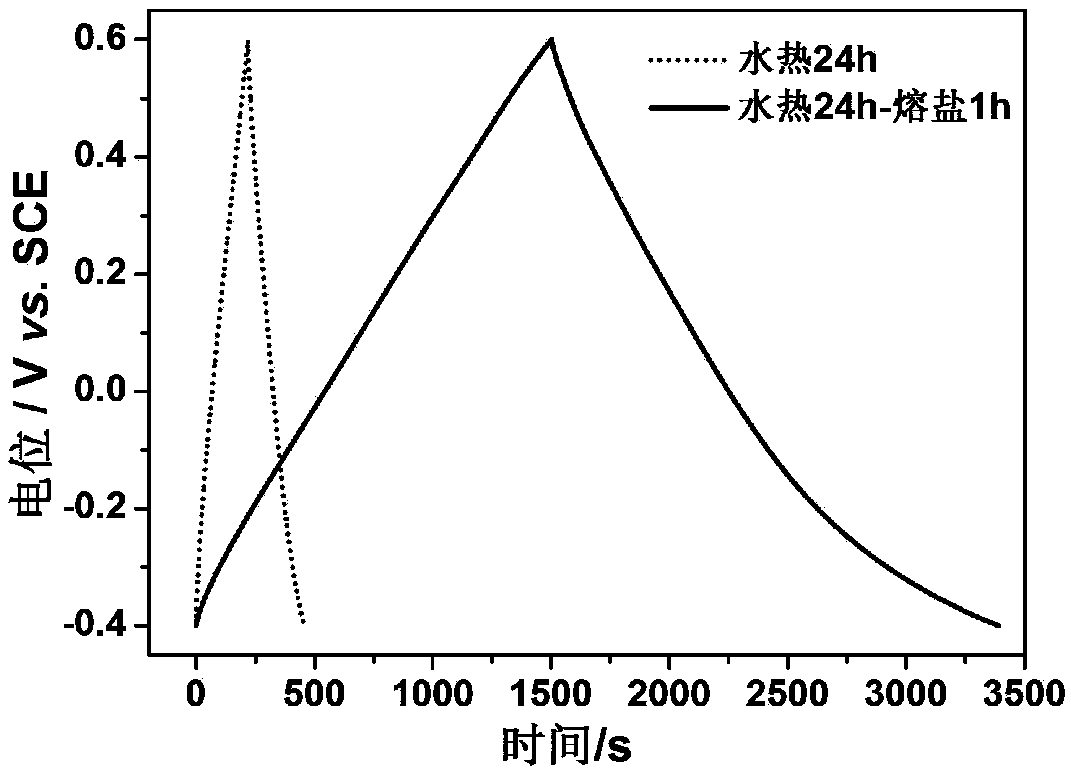

[0032] (3) Molten salt activation treatment: take 2.0g of hydrothermal carbon obtained in step (2), add 8.0gNa 2 CO 3 -K 2 CO 3 Mix the salt, put it in a corundum porcelain boat after mixing evenly, put it in a tube furnace, and put it in the N 2 Under the protection of gas, calcined at 85...

Embodiment 2

[0035] A kind of method utilizing water hyacinth to prepare porous carbon material, comprises the following steps:

[0036] (1) Pretreatment of water hyacinth: take the stem of water hyacinth, wash it, and air-dry it naturally for 5-6 days, then dry it in an oven at 105°C for 24 hours, then crush the dried stem of water hyacinth with a pulverizer, and dry it for 40 Mesh sieve;

[0037] (2) Hydrothermal treatment: Weigh 6.0g of water hyacinth powder in step (1), add 30mL of deionized water into the hydrothermal reaction kettle, mix well; then place the reaction kettle at 200°C for hydrothermal reaction for 24h , filter and dry after the reaction to obtain lignite-like biomass hydrothermal carbon;

[0038] (3) Molten salt activation treatment: take 2.0g of hydrothermal carbon obtained in step (2), add 8.0gNa 2 CO 3 -K 2 CO 3 Mix the salt, put it in a corundum porcelain boat after mixing evenly, put it in a tube furnace, and put it in the N 2 Under the protection of gas, ca...

Embodiment 3

[0041] A kind of method utilizing water hyacinth to prepare porous carbon material, comprises the following steps:

[0042] (1) Pretreatment of water hyacinth: take the stem of water hyacinth, wash it, and air-dry it naturally for 5-6 days, then dry it in an oven at 105°C for 24 hours, then crush the dried stem of water hyacinth with a pulverizer, and dry it for 40 Mesh sieve;

[0043] (2) Hydrothermal treatment: Weigh 6.0g of water hyacinth powder in step (1), add 60mL of deionized water into the hydrothermal reaction kettle, mix well; then place the reaction kettle at 180°C for hydrothermal reaction for 24h , filter and dry after the reaction to obtain lignite-like biomass hydrothermal carbon;

[0044] (3) Molten salt activation treatment: take 2.0g of hydrothermal carbon obtained in step (2), add 8.0gNa 2 CO 3 -K 2 CO 3 Mix the salt, put it in a corundum porcelain boat after mixing evenly, put it in a tube furnace, and put it in the N 2 Under the protection of gas, ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

| Specific capacitance value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com