Waterproof coating for metal roof and preparation and using method of coating

A waterproof coating and metal roofing technology, applied in the field of coating chemistry, can solve the problems of insufficient adhesion and mechanical properties, inability to effectively protect the building surface for a long time, water seepage and other problems, and achieve good waterproof effect, simple operability, The effect of good elasticity and fatigue resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

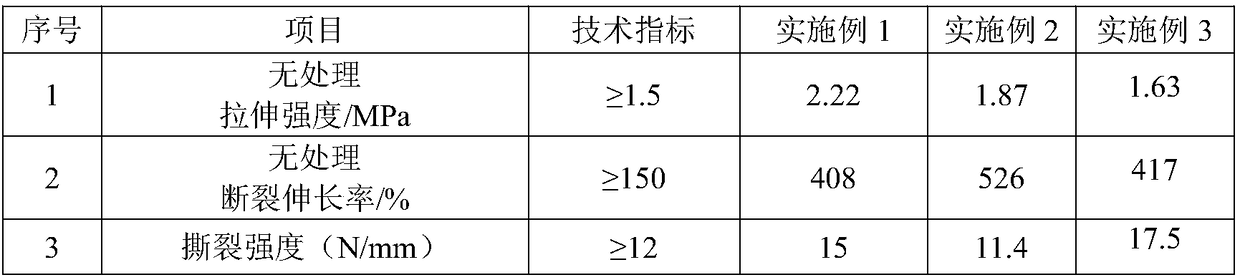

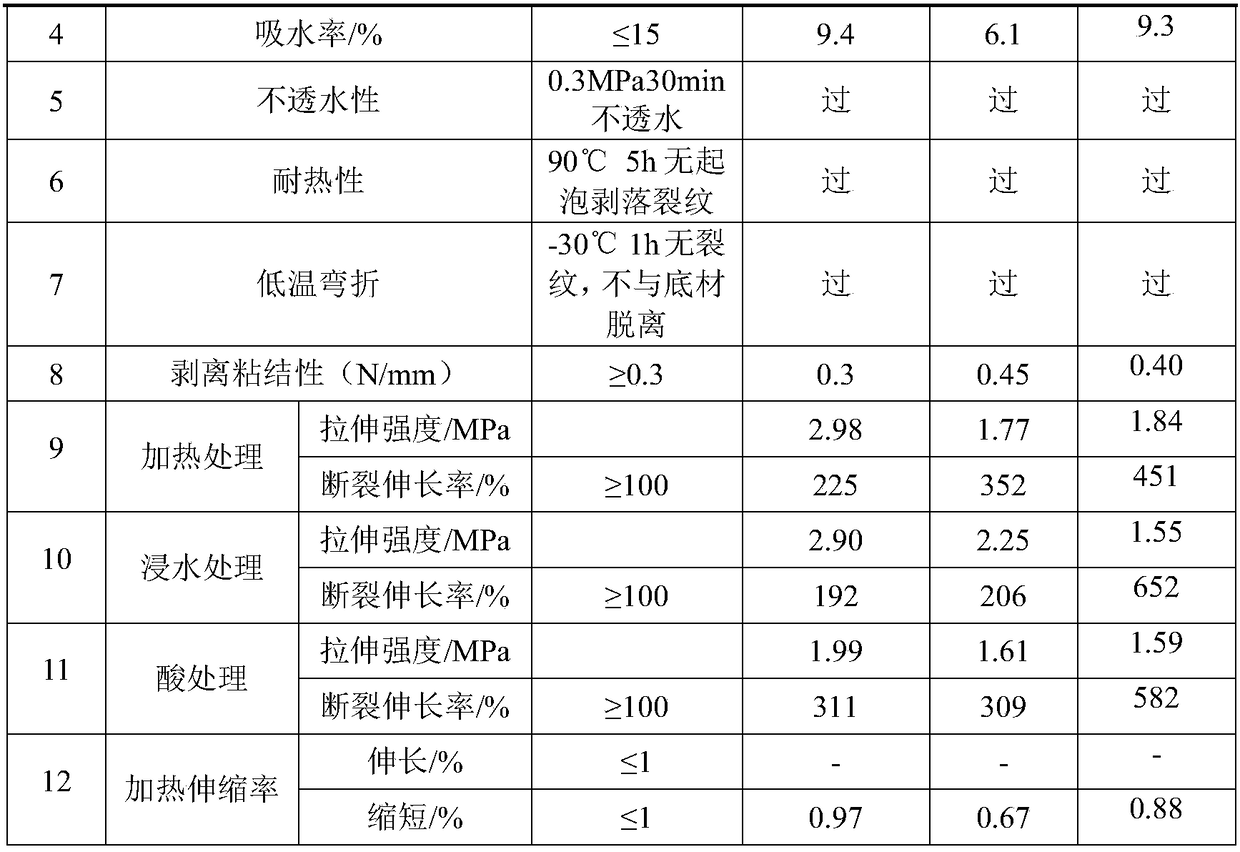

Examples

Embodiment 1

[0023] A kind of waterproof coating for metal roof, including deionized water 145kg, hydroxyethyl cellulose 0.5kg, defoamer 4kg, 2-amino-2-methyl-1-propanol 1kg, ammonium salt 6kg, nonionic Surfactant 1.5kg, titanium dioxide 470kg, water-based acrylic emulsion 350kg, potassium tripolyphosphate 1kg, propylene glycol 8kg, plasticizer 6kg, fungicide 1.8kg, polyurethane thickener 8kg, alkali swelling thickener 75kg, of which, alkali The solid content of the swelling thickener is 50%.

[0024] A preparation method for a waterproof coating for metal roofs, comprising the steps of:

[0025] (1) Add deionized water, hydroxyethyl cellulose and 2kg of defoamer into the dispersion kettle, and mix well;

[0026] (2) Add 2-amino-2-methyl-1-propanol, ammonium salt, non-ionic surfactant, titanium dioxide and mix evenly, then disperse at high speed for 20-50 minutes;

[0027] (3) Add water-based acrylic emulsion, potassium tripolyphosphate, propylene glycol, plasticizer, bactericide and the...

Embodiment 2

[0030] A kind of waterproof paint for metal roof, including deionized water 148kg, hydroxyethyl cellulose 0.3kg, defoamer 4kg, 2-amino-2-methyl-1-propanol 1kg, ammonium salt 7kg, nonionic Surfactant 1.8kg, titanium dioxide 270kg, barium sulfate 210kg, water-based acrylic emulsion 320kg, potassium tripolyphosphate 1kg, propylene glycol 6kg, plasticizer 4kg, fungicide 1.5kg, polyurethane thickener 6.6kg, alkali swelling thickener 70kg, wherein the solid content of the alkali-swellable thickener is 45%.

[0031] A preparation method for a waterproof coating for metal roofs, comprising the steps of:

[0032] (1) Add deionized water, hydroxyethyl cellulose and 2kg of defoamer into the dispersion kettle, and mix well;

[0033] (2) Add 2-amino-2-methyl-1-propanol, ammonium salt dispersant, non-ionic surfactant, titanium dioxide, barium sulfate and mix well, then disperse at high speed for 20-50 minutes;

[0034] (3) Add water-based acrylic emulsion, potassium tripolyphosphate, prop...

Embodiment 3

[0037] A kind of waterproof paint for metal roof, including deionized water 160kg, hydroxyethyl cellulose 1.0kg, defoamer 6kg, 2-amino-2-methyl-1-propanol 1.5kg, ammonium salt 6kg, alkane Base polyoxyethylene ether 1.5kg, nonionic surfactant 3kg, titanium dioxide 50kg, calcium carbonate 405kg, water-based acrylic emulsion 450kg, potassium tripolyphosphate 1.5kg, propylene glycol 10kg, plasticizer 8kg, fungicide 2.5kg, polyurethane Thickener 7.5kg, alkali-swellable thickener 96kg, wherein, the mesh number of calcium carbonate is 800 mesh, and the solid content of alkali-swellable thickener is 55%.

[0038] A preparation method for a waterproof coating for metal roofs, comprising the steps of:

[0039] (1) Add deionized water, hydroxyethyl cellulose and 3kg defoamer into the dispersion kettle, and mix well;

[0040] (2) Add 2-amino-2-methyl-1-propanol, ammonium salt, alkyl polyoxyethylene ether, nonionic surfactant, titanium dioxide, calcium carbonate and mix well, then dispers...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com