A method for the enrichment and separation of glycopeptides based on two-dimensional porous crystalline nitrogen-doped carbon materials

A technology of nitrogen-doped carbon and crystals, which is applied in the fields of material analytical chemistry and post-translational modification proteomics, can solve the problems of cumbersome hydrazide chemical method, low glycopeptide ionization efficiency, and only targeting specific glycoforms. Achieve the effect of simple and controllable operation, high enrichment selectivity and high selectivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

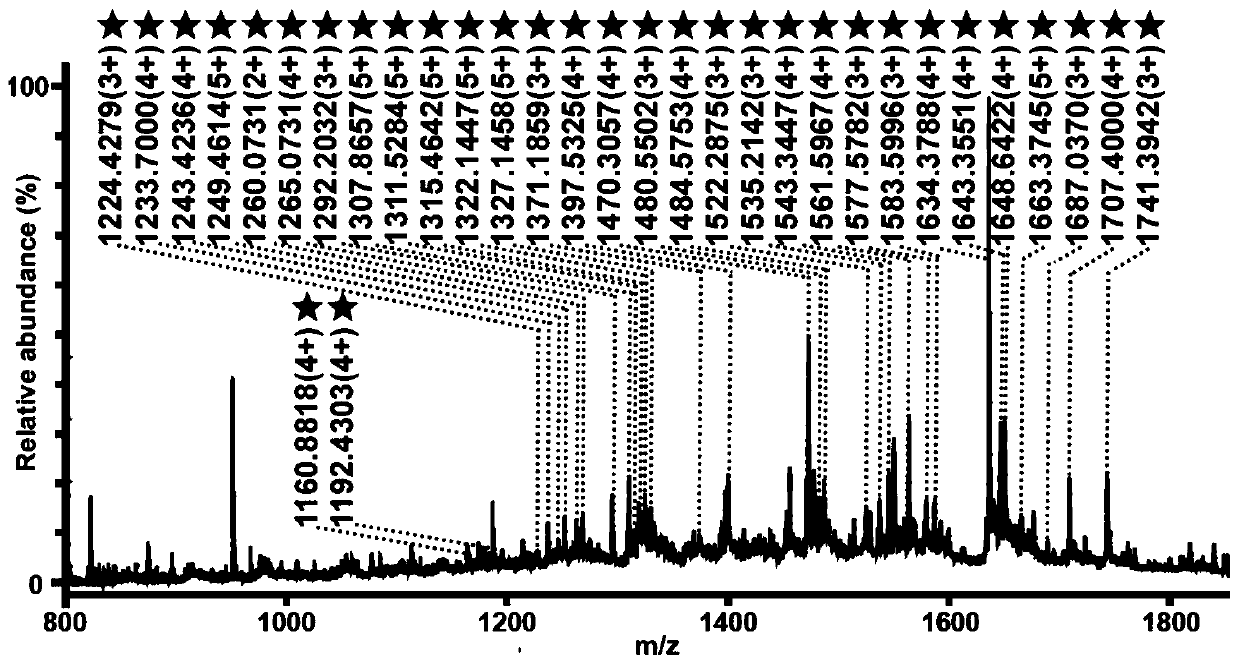

[0060] Using C2N as the enrichment material, glycopeptides were enriched in SPE mode. Put 2 mg of material into a centrifuge tube, redissolve 5 μL of spin-dried fetuin hydrolyzate (1 mg / mL) in 100 μL of 85% acetonitrile / 0.1% formic acid solution, after loading, use 80% of the volume of 200 μL respectively Wash with acetonitrile / 0.1% formic acid, 70% acetonitrile / 0.1% formic acid and 60% acetonitrile / 0.1% formic acid solution, and finally elute with 30 μL of 50% acetonitrile / 0.1% formic acid solution. The eluate is analyzed directly on the mass spectrometer. The result is as figure 1 As shown, the signals of glycopeptides are all in the mass spectrum, indicating that the materials used have high selectivity for glycopeptides.

Embodiment 2

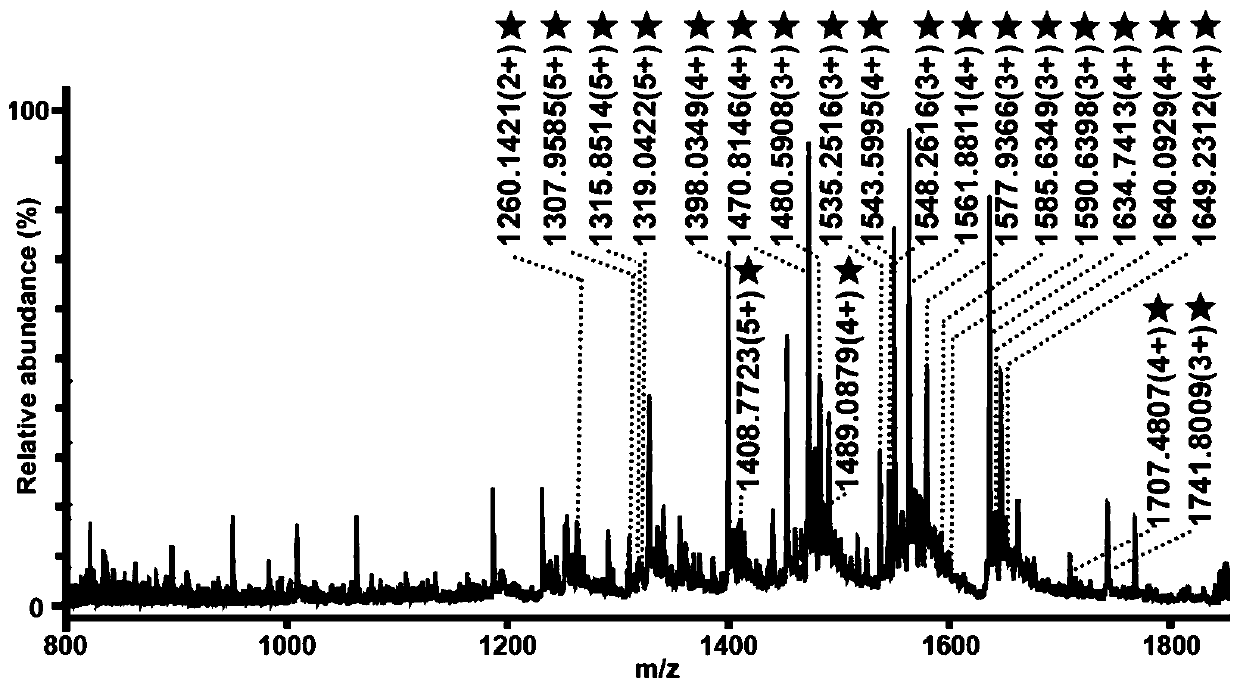

[0062] Using C2N as the enrichment material, glycopeptides were enriched in dSPE mode. Put 2 mg of material into a centrifuge tube, redissolve 5 μL of spin-dried fetuin hydrolyzate (1 mg / mL) in 100 μL of 85% acetonitrile / 1% formic acid solution, after loading, use 80% of the volume of 200 μL respectively Wash with acetonitrile / 1% formic acid, 70% acetonitrile / 1% formic acid and 60% acetonitrile / 1% formic acid solution, and finally elute with 30 μL of 50% acetonitrile / 1% formic acid solution. The eluate is analyzed directly on the mass spectrometer. The result is as figure 2 As shown, the signals of glycopeptides are all in the mass spectrum, indicating that the materials used have high selectivity for glycopeptides.

Embodiment 3

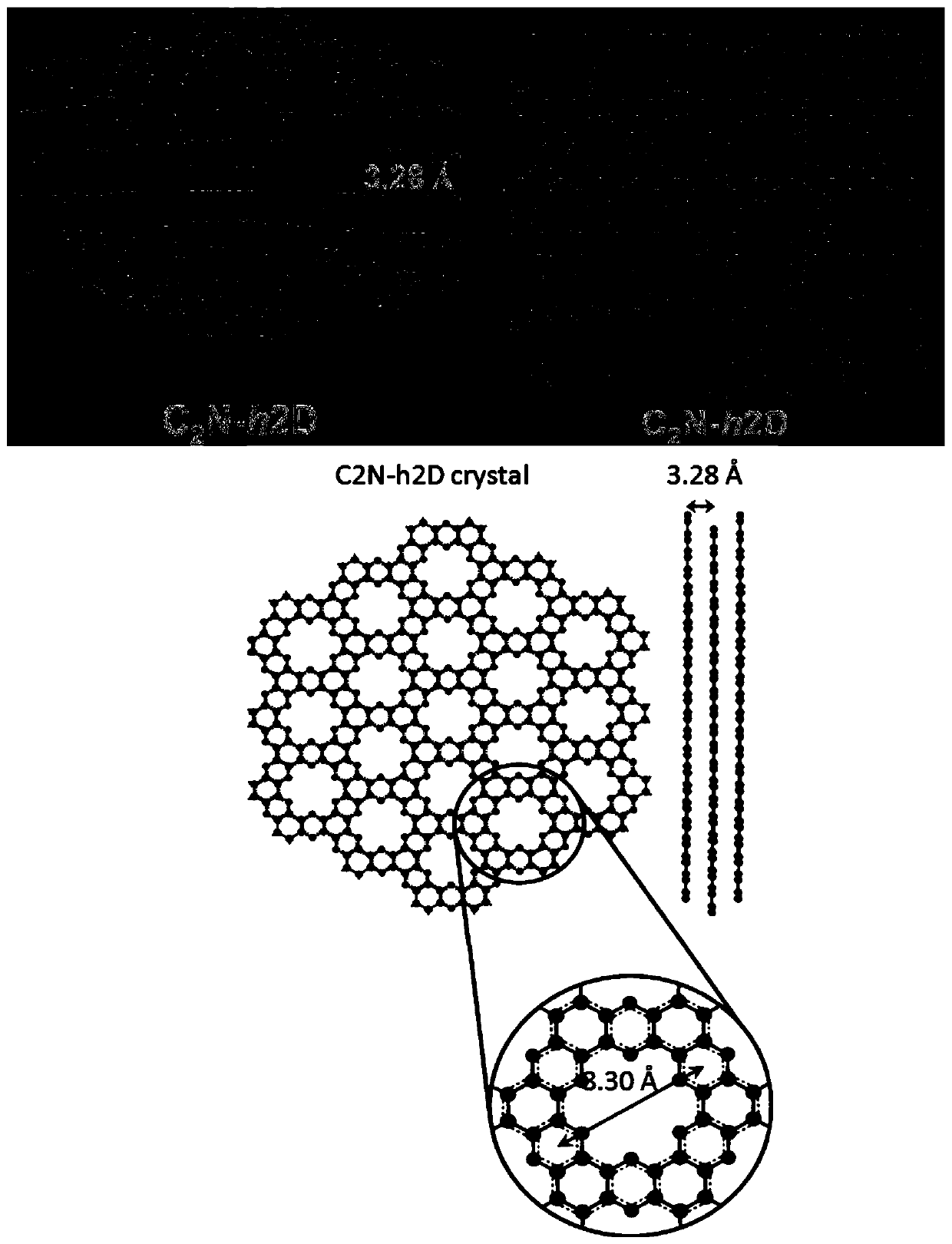

[0064] Using C2N as the enrichment material, the schematic diagram of the sheet structure and layer spacing of the material used, as well as the schematic diagram of the pore size and pore structure are as follows image 3 As shown, glycopeptides were enriched in SPE mode. Put 1 mg of the material into the tip, redissolve 5 μL of the spin-dried fetuin hydrolyzate (1 mg / mL) in 30 μL of 85% acetonitrile / 0.1% formic acid solution, after loading the sample, use 30 μL of 80% acetonitrile / 1% formic acid, 70% acetonitrile / 1% formic acid and 60% acetonitrile / 1% formic acid solution, and finally eluted with 30 μL of 50% acetonitrile / 1% formic acid solution. The eluate is analyzed directly on the mass spectrometer.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com