Tissue defect repairing film loader and preparation method thereof

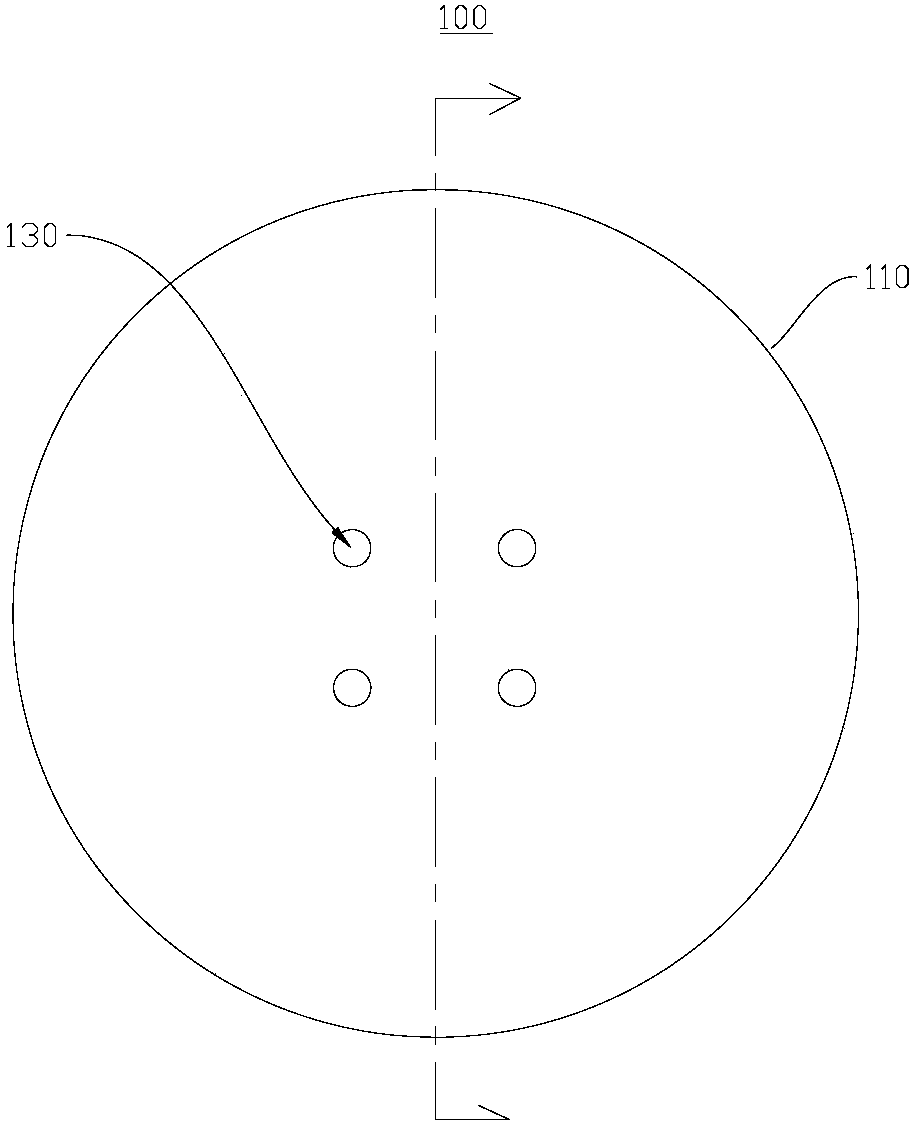

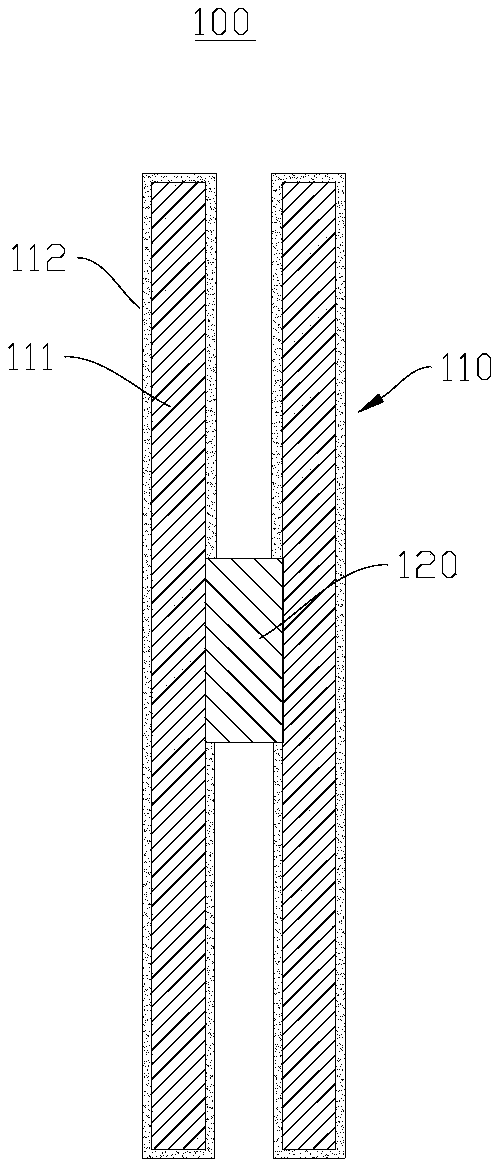

A carrier and tissue technology, used in tissue regeneration, medical science, nose implants, etc., can solve the problems of repairing membrane without a supporting carrier or the carrier is not easy to plasticize new wounds and complications, etc. The effect of uniform thickness and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The preparation method of the tissue defect repair membrane carrier of this embodiment includes:

[0035] (1) Put dimethyl / methyl vinyl siloxane copolymer and fiber-reinforced silica in a mass ratio of 0.8:1.2 into a rubber mixer and knead for 1 min, then pour it into a mold and heat it at 160°C Forming under vacuum for 3 minutes, and then performing vulcanization treatment under an inert atmosphere at 200°C to obtain the carrier body;

[0036] (2) Coating the polymer polysaccharide solution on the surface of the carrier body by casting method, standing for 15 minutes, and then drying in an oven at 40°C for 8 hours. Preferably, the polymer polysaccharide is chitosan.

[0037] (3) Soak the dried carrier body in a 0.08 mol / L sodium hydroxide solution for 3 hours, wash with distilled water until the solution becomes neutral, and then dry to prepare the carrier.

Embodiment 2

[0039] The preparation method of the tissue defect repair membrane carrier of this embodiment includes:

[0040] (1) Put the dimethyl / methyl vinyl siloxane copolymer and fiber-reinforced silica into the rubber mixer according to the mass ratio of 1.2:0.8 and knead for 20 minutes, then pour it into the mold and put it in the 100℃ Forming under vacuum for 2 minutes, and then performing vulcanization treatment under an inert atmosphere at 300°C to obtain the carrier body;

[0041] (2) Coating the polymer polysaccharide solution on the surface of the carrier body by casting method, standing for 20 minutes, and then drying in an oven at 50°C for 6 hours. Preferably, the polymer polysaccharide is one or more combinations of sodium hyaluronate and its derivatives, and cellulose polysaccharide derivatives.

[0042] (3) Soak the dried carrier body in a 0.12 mol / L sodium hydroxide solution for 2 hours, wash with distilled water until the solution becomes neutral, and then dry to prepar...

Embodiment 3

[0044] The preparation method of the tissue defect repair membrane carrier of this embodiment includes:

[0045] (1) Put dimethyl / methyl vinyl siloxane copolymer and fiber-reinforced silica into the rubber mixer according to the mass ratio of 1:1 and knead for 15 minutes, then pour it into the mold and place it in the empty state at 120 Molding for 2.5 minutes, and then vulcanized under an inert atmosphere at 250°C to obtain the main body of the carrier;

[0046](2) Coating the polymer polysaccharide solution on the surface of the carrier body by casting method, standing for 18 minutes, and then drying in an oven at 45°C for 7 hours. Preferably, the polymer polysaccharide is cellulose polysaccharide.

[0047] (3) Soak the dried carrier body in a 0.1 mol / L sodium hydroxide solution for 2.5 hours, wash with distilled water until the solution becomes neutral, and then dry to prepare the carrier.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com