Sintering flue gas heating denitration device and sintering flue gas heating denitration method

A technology for sintering flue gas and denitration, which is applied in combustion methods, separation methods, lighting and heating equipment, etc., can solve the problems of low utilization rate of waste heat and high operating costs, and achieve the effect of improving recycling rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

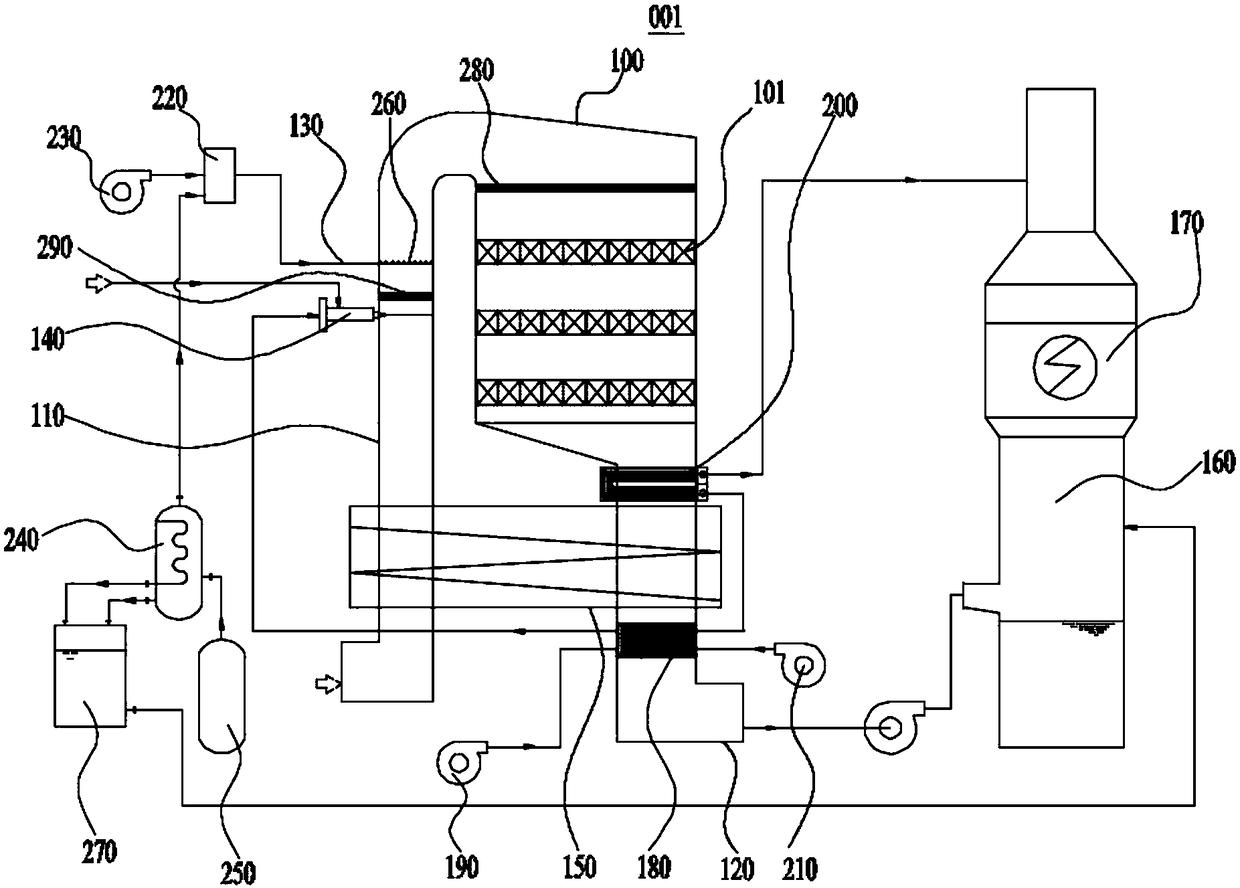

[0035] Please refer to figure 1 , figure 2 and image 3 As shown, the embodiment of the present invention provides a sintering flue gas heating denitration equipment 001, which includes a denitration tower 100 with a three-layer denitration catalyst 101 inside, and an intake flue 110 and an exhaust flue 120 connected to the denitration tower 100, The intake flue 110 is connected with an ammonia conveying pipe 130 and a flue burner 140 for heating the flue gas flowing through the intake flue 110, and the intake flue 110 and the exhaust flue 120 are connected with a Flue gas for heat exchange—flue gas reheater 150 , exhaust flue 120 is connected to desulfurization tower 160 , and wet electrostatic precipitator 170 is installed on the top of desulfurization tower 160 .

[0036] The sintering flue gas heating and denitrification equipment 001 provided by the embodiment of the present invention can effectively utilize the waste heat of the exhaust flue gas after denitrification ...

Embodiment 2

[0045] Please refer to figure 2 , image 3 and Figure 4 As shown, the embodiment of the present invention also provides a sintering flue gas heating and denitrification system, which includes the above-mentioned sintering flue gas heating and denitrification equipment 001, and the first denitration catalyst 101 is installed between adjacent denitrification catalysts 101. Three decompression plates 300, the third decompression plate 300 can reduce the flow rate of the sintering flue gas passing through the denitration catalyst 101, so that the sintering flue gas mixed with ammonia can fully contact the denitration catalyst 101 and react to remove nitrogen oxides.

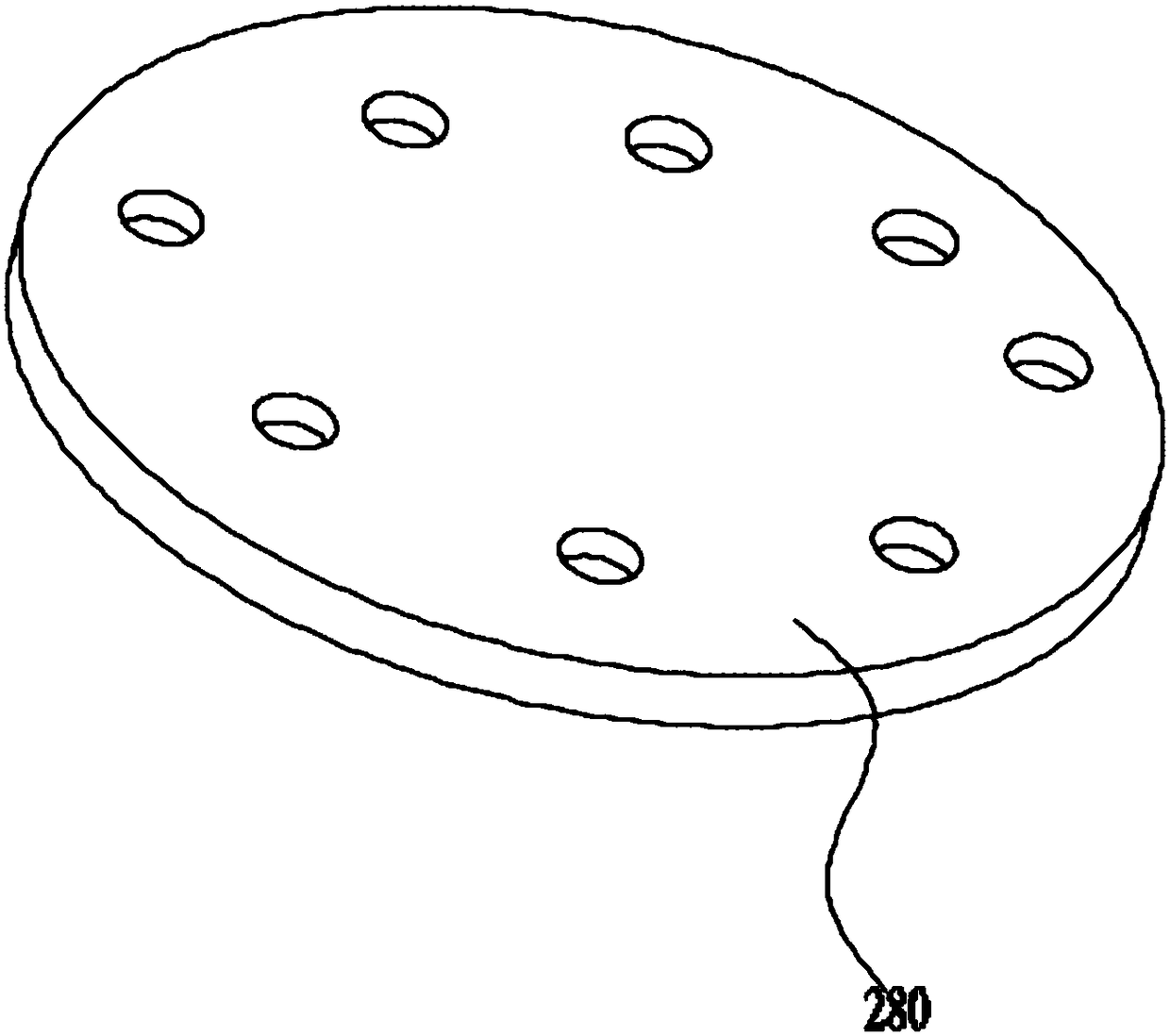

[0046] The structures of the first decompression plate 280 , the second decompression plate 290 and the third decompression plate 300 are similar, only the size ratio is different.

Embodiment 3

[0048] Please refer to figure 1 , figure 2 and image 3 As shown, the embodiment of the present invention provides a sintering flue gas heating denitrification method, which is realized by using the sintering flue gas heating denitrification equipment 001 provided in the above-mentioned embodiment 1, and mainly includes the following steps:

[0049] The sintering flue gas passes through the intake flue 110 and is heated to 250-260°C by heat exchange through the flue gas-flue gas reheater 150, and heated to 300-320°C by the flue burner 140, and then mixed with the mixer 220 The mixed gas of sintering flue gas and ammonia gas is mixed and passed to the surface of the denitrification catalyst 101, and the catalytic reaction is to obtain denitrification clean flue gas;

[0050] The denitrified flue gas is sequentially cooled to 290-300°C through the secondary air preheater 200 installed on the exhaust flue 120, and then cooled to 160-170°C through the flue gas-flue gas reheater...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com