Method for removing CO2 from biological hydrogen alkane gas by phase-changing solvent prepared from ethylenediamine and DMA (N,N-dimethylacetamide)

An ethylenediamine and absorbent technology, which is applied in the fields of energy conservation, environmental protection and CO2 emission reduction, can solve the problems of strong volatility, high cost, restricting the engineering application of two-phase absorbents, etc., and achieves increased absorption capacity, shortened absorption balance time, The effect of increasing the removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

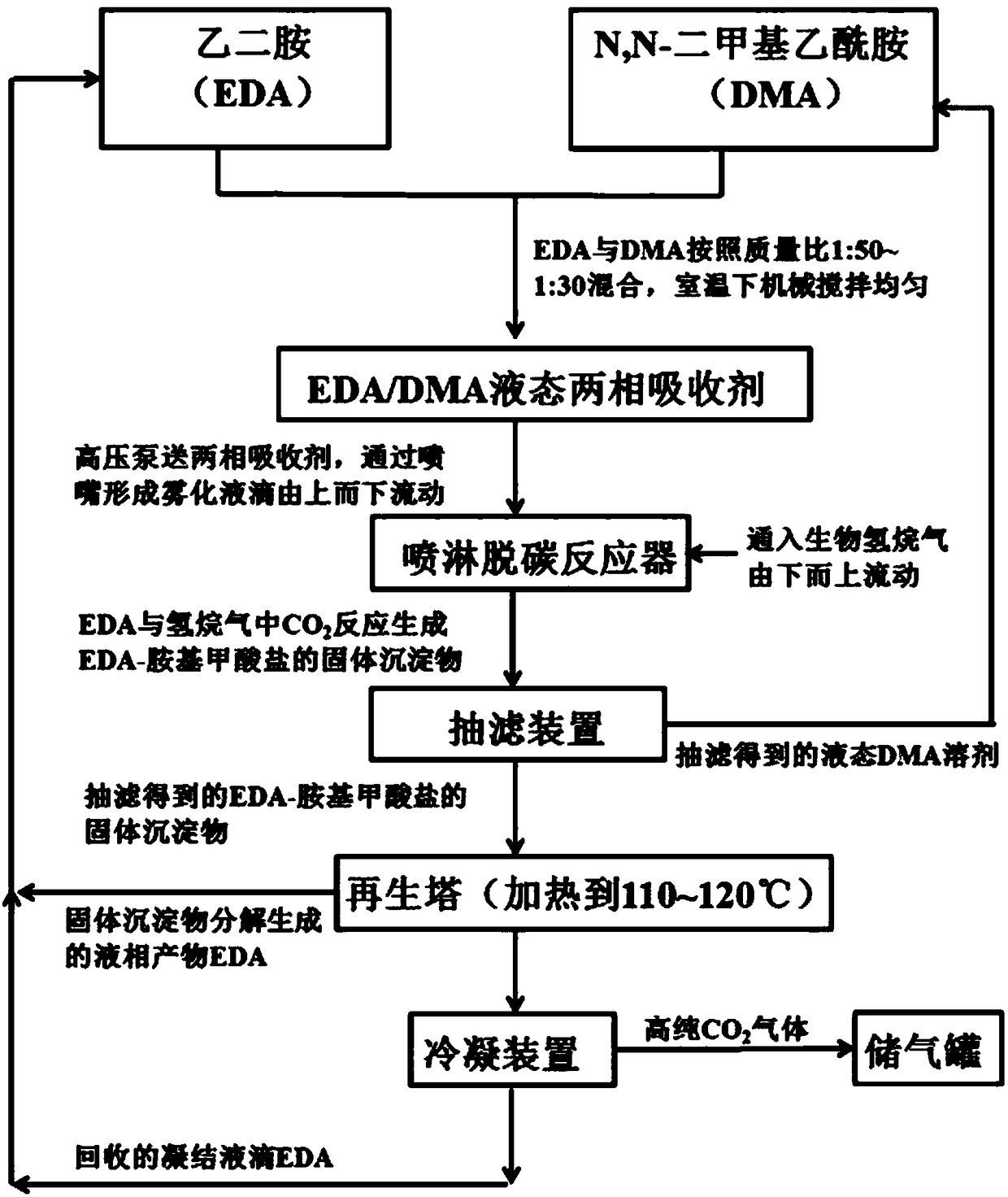

[0024] Weigh the theoretical absorption of CO 2 1.0mol CO capacity 2 / mol chain amine-based absorbent ethylene diamine (EDA), mixed with low volatility liquid organic solvent N,N-dimethylacetamide (DMA) at a mass ratio of 1:50, and mechanically stirred at room temperature 5 Minutes, a uniformly mixed EDA / DMA liquid two-phase absorbent is obtained. Use a high-pressure pump to send the liquid two-phase absorbent EDA / DMA into the spray decarburization reactor, and form atomized droplets through the nozzle to flow from top to bottom, and to flow from bottom to top of the biohydrogen gas (volume concentration of each component) 21% H 2 , 40% CH 4 , 38% CO 2 , 0.8% of H 2 S, 0.2% H 2 O) Perform countercurrent mixing. CO in hydrogen gas 2 First, it is physically dissolved in the DMA solvent, and then chemically reacts with the absorbent EDA to form a solid precipitate of EDA-carbamate. The test result is: the two-phase absorbent EDA / DMA removes CO 2 Rate ratio alcohol amine aqueous s...

Embodiment 2

[0026] Weigh the theoretical absorption of CO 2 1.0mol CO capacity 2 / mol chain amine-based absorbent ethylene diamine (EDA), mixed with low volatility liquid organic solvent N,N-dimethylacetamide (DMA) at a mass ratio of 1:40, and mechanically stirred at room temperature for 10 Minutes, a uniformly mixed EDA / DMA liquid two-phase absorbent is obtained. Use a high-pressure pump to send the liquid two-phase absorbent EDA / DMA into the spray decarburization reactor, and form atomized droplets through the nozzle to flow from top to bottom, and to flow from bottom to top of the biohydrogen gas (volume concentration of each component) 5% H 2 , 63% of CH 4 , 30% CO 2 , 1% H 2 S, 1% H 2 O) Perform countercurrent mixing. CO in hydrogen gas 2 First, it is physically dissolved in the DMA solvent, and then chemically reacts with the absorbent EDA to form a solid precipitate of EDA-carbamate. The test result is: two-phase absorbent EDA / DMA removes CO 2 Rate ratio alcohol amine aqueous solut...

Embodiment 3

[0028] Weigh the theoretical absorption of CO 2 1.0mol CO capacity 2 / mol chain amine-based absorbent ethylene diamine (EDA), mixed with the low-volatility liquid organic solvent N,N-dimethylacetamide (DMA) at a mass ratio of 1:30, and mechanically stirred at room temperature 15 Minutes, a uniformly mixed EDA / DMA liquid two-phase absorbent is obtained. Use a high-pressure pump to send the liquid two-phase absorbent EDA / DMA into the spray decarburization reactor, and form atomized droplets through the nozzle to flow from top to bottom, and to flow from bottom to top of the biohydrogen gas (volume concentration of each component) 14% H 2 , 35% CH 4 , 50% CO 2 , 0.2% of H 2 S, 0.8% H 2 O) Perform countercurrent mixing. CO in hydrogen gas 2 First, it is physically dissolved in the DMA solvent, and then chemically reacts with the absorbent EDA to form a solid precipitate of EDA-carbamate. The test result is: two-phase absorbent EDA / DMA removes CO 2 Rate ratio alcohol amine aqueous ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com