Composition used for preparing anti-corrosion heat-insulation automobile film and preparation method thereof

A technology of automotive film and composition, applied in the direction of film/sheet adhesive, anti-corrosion coating, film/sheet release coating, etc., can solve the problems of reducing service life, achieve excellent effect, improve stability, Good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

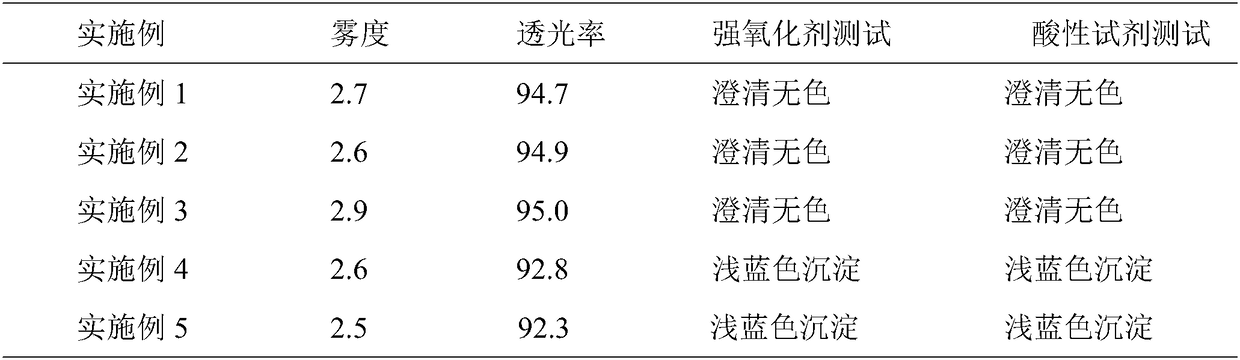

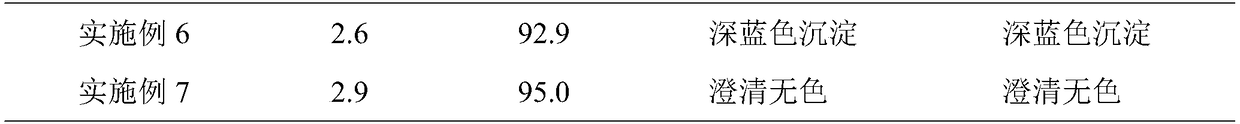

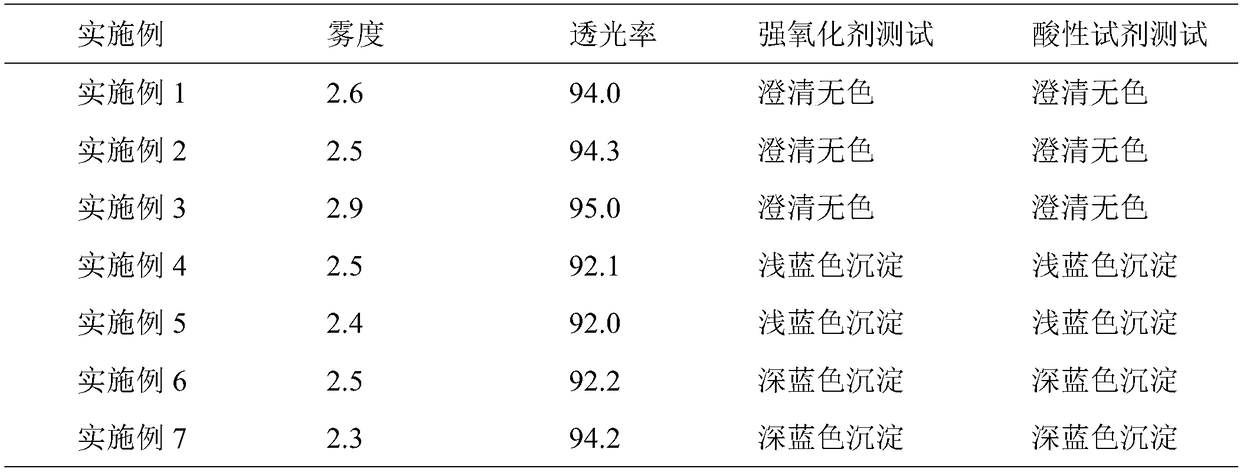

Examples

preparation example Construction

[0031] A method for preparing a sunscreen and heat insulation car film 1, comprising the steps of:

[0032] (1) The base layer is composed of a copolymer and a plasticizer;

[0033] (2) The anti-corrosion layer is coated on the inner surface of the base layer, mainly composed of butyl hydroxybenzoate, tert-butyldimethylsilyl chloride, antioxidant, poly-L-sodium glutamate;

[0034] (3) The thermal insulation layer is composed of ethyl sorbate, active epoxy resin diluent, low methylated melamine formaldehyde resin, and phenylethyl ester, and the thermal insulation layer is coated on the outer surface of the base layer;

[0035] (4) The wear-resistant layer is made up of micropowder silica gel, propylene glycol p-toluate, microcrystalline cellulose and epoxy resin, and the wear-resistant layer is coated on the surface of the anti-corrosion layer;

[0036] (5) The protective film layer is composed of carboxyl-terminated hyperbranched polyester, antimony oxide, and phosphoric acid...

Embodiment 1

[0049] a. The base layer is made up of a copolymer and a plasticizer; the main material composition of the base layer is composed of 15 parts by weight of a copolymer and 6 parts of a plasticizer, wherein the copolymer is polypropylene-diene- Polystyrene-polypropylene block copolymer, the preparation process of the copolymer is: use rosin acid soap as emulsifier, use sodium persulfate as initiator, add appropriate amount of dodecyl mercaptan and palladium carbon, the prescription amount of acrylic acid Produced by emulsification copolymerization of diene and styrene.

[0050] b. The further steps of the anti-corrosion layer:

[0051] (1) butyl hydroxybenzoate and tert-butyldimethylsilyl chloride in parts by weight are dissolved in n-butane, stirred for 15min, and the rotating speed is 500rpm and a small amount of farnesol is added in the mixed solution, for subsequent use

[0052] (2) Slowly dissolve the poly-L-sodium glutamate of the prescribed amount in the mixed solution o...

Embodiment 2

[0067] Make corresponding changes according to embodiment one, 6 parts of polypropylene glycol diglycidyl ethers, 20 parts of polypropylene-polystyrene-polypropylene block copolymers, 8 parts of dioctyl phthalates, 4 parts of microcrystalline cellulose , 4 parts of sodium metabisulfite, 7 parts of antimony oxide, 16 parts of polyacrylate, 8 parts of carboxyl-terminated hyperbranched polyester, 9 parts of propylene glycol p-toluate, 9 parts of tert-butyldimethylsilyl chloride, dodecyl 10 parts of sodium benzenesulfonate, 12 parts of low methyl etherified melamine formaldehyde resin, 9 parts of phenylethyl ester, 12 parts of poly-L-sodium glutamate, 18 parts of butyl hydroxybenzoate, 5 parts of micropowdered silica gel, ethyl sorbate 20 parts of ester. The main material components of the anticorrosion layer are recorded in parts by weight: 30 parts of n-butane, 5 parts of farnesol, 1.5 parts of leveling agent, and 2 parts of defoamer.

[0068] The main material components of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com