Cobaltous ferrocyanide PVDF (poly(vinylidene fluoride)) hollow fibrous membrane as well as preparation method and use thereof

A ferrocyanide and fiber membrane technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of clogging membrane pores and reducing membrane performance, achieving high loading capacity and no secondary pollution , The effect of simple operation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

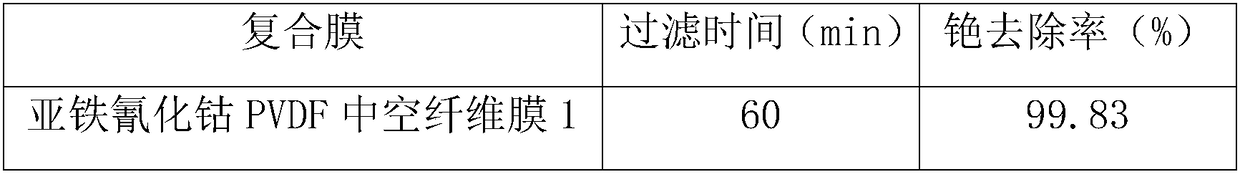

Embodiment 1

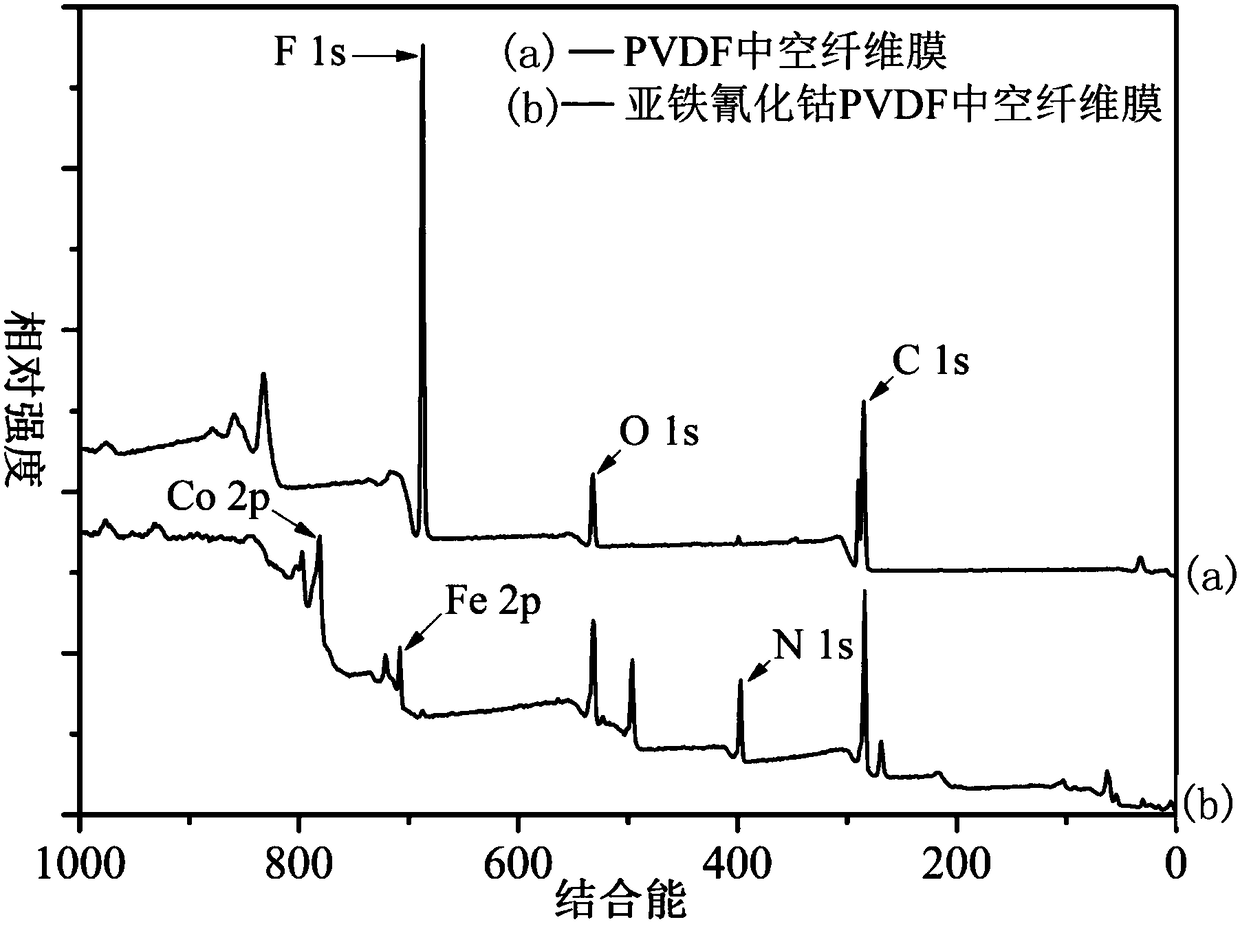

[0025] 1) PVDF hollow fiber membrane cleaning: seal both ends of the PVDF hollow fiber membrane with epoxy resin, and after solidification at room temperature for 24 hours, clean it in ultrapure water for 12 hours, and then place it in ethanol solution for 60 minutes to remove excess membrane surface. Particles and organic pollutants, the cleaned basement membrane is obtained, and the X-ray photoelectron energy spectrum of the membrane surface is as follows figure 1 As shown in (a), the scanning electron microscope spectrum of its membrane surface is as follows figure 2 as shown in (a);

[0026] 2) Chemical activation of the membrane surface: put the base membrane cleaned in step 1) into a potassium hydroxide solution with a concentration of 1mol / L, add 5g / L tetrabutylammonium fluoride, and let it stand at a constant temperature of 45°C for 60min. The surface of the membrane is hydroxylated; then the membrane is placed in a sodium bisulfite solution with a concentration of 1...

Embodiment 2

[0030] In this example, PVDF hollow fiber membrane cleaning, membrane surface chemical activation, intermediate SiO 2Film surface immobilization and cobalt ferrocyanide curing steps are the same as in Example 1, the difference is that in step 3) aminated SiO 2 The concentration is 0.1% (mass / volume), and the prepared membrane is recorded as cobalt ferrocyanide PVDF hollow fiber membrane 2.

Embodiment 3

[0032] In this example, PVDF hollow fiber membrane cleaning, membrane surface chemical activation, intermediate SiO 2 Film surface immobilization and cobalt ferrocyanide curing steps are the same as in Example 1, the difference is that in step 3) aminated SiO 2 The concentration is 0.05% (mass / volume), and the prepared membrane is recorded as cobalt ferrocyanide PVDF hollow fiber membrane 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com