A kind of waste water treatment agent, preparation method and using method thereof

A technology of wastewater treatment agent and acid effervescent agent, which is applied in water/sewage treatment, oxidized water/sewage treatment, adsorbed water/sewage treatment, etc. problem, to achieve the effect of enhancing the treatment effect and reducing the catalytic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] The preparation method of iron carbon sphere particles: first, mix and stir iron powder, activated carbon, graphite, calcium carbonate powder, bentonite and attapulgite according to the mass ratio of 6:2:0.5:0.5:0.5:1, and perform wet granulation , dried and sieved to obtain raw material particles; then the obtained raw material particles were transferred to a tube furnace, and sintered at 800°C for 6 hours under the protection of nitrogen to form iron-carbon spherical particles. Among them, calcium carbonate powder can reduce the degradation energy of organic matter during the reaction process, and bentonite and attapulgite can slow down the compaction of iron-carbon sphere particles.

[0053] The preparation method of coated potassium ferrate: use polyethylene wax as the coating wall material, first heat the polyethylene wax to 150 degrees Celsius and melt, then add potassium ferrate according to the ratio of polyethylene wax and potassium ferrate at 1:1, and ultrasoni...

Embodiment 1

[0056] A kind of waste water treatment agent, is made up of compound A and compound B,

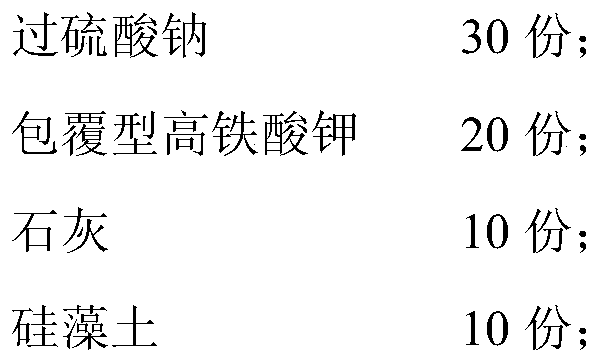

[0057] The compound A includes the following components in parts by weight:

[0058] Iron carbon ball particles 20Kg;

[0059] Citric acid 10Kg;

[0060] The compound B includes the following components in parts by weight:

[0061]

[0062] The mass ratio of the complex A to the complex B is 1:2.33.

[0063] Its preparation method is:

[0064] Step 1. Weigh 20Kg of iron carbon sphere particles and 10Kg of citric acid, and mix them evenly to obtain compound A;

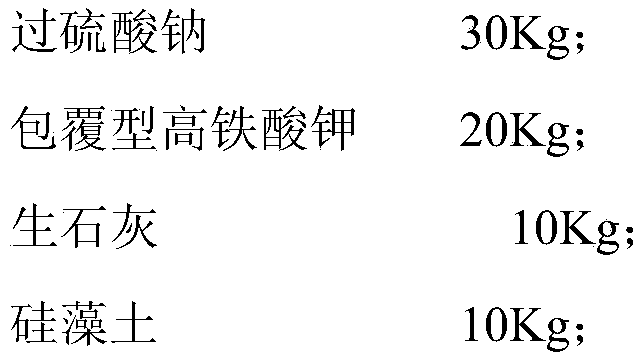

[0065] Step 2. After activating the diatomite, weigh 30Kg of sodium persulfate, 20Kg of slow-release potassium ferrate, 10Kg of quicklime and 10Kg of diatomite, and mix them evenly to obtain compound B;

[0066] Step 3. The mass ratio of the complex A to the complex B is 1:2.33. After weighing the complex A and the complex B, they are packaged and stored respectively.

[0067] Its usage method is:

[0068] First, 0.3Kg of ...

Embodiment 2

[0072] A kind of waste water treatment agent, is made up of compound A and compound B,

[0073] The compound A includes the following components in parts by weight:

[0074] Iron carbon ball particles 20Kg;

[0075] Citric acid 10Kg;

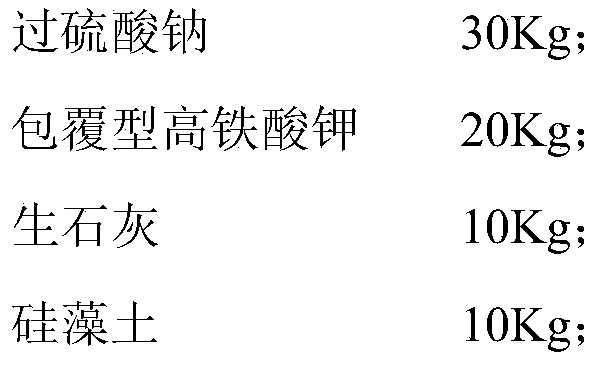

[0076] The compound B includes the following components in parts by weight:

[0077]

[0078] The mass ratio of the complex A to the complex B is 1:2.33.

[0079] Its preparation method is:

[0080] Step 1. Weigh 30Kg of iron carbon sphere particles and 10Kg of citric acid, and mix them evenly to obtain compound A;

[0081] Step 2. After activating the diatomite, weigh 30Kg of sodium persulfate, 20Kg of slow-release potassium ferrate, 10Kg of quicklime and 10Kg of diatomite, and mix them evenly to obtain compound B;

[0082] Step 3. The mass ratio of the complex A to the complex B is 1:2.33. After weighing the complex A and the complex B, they are packaged and stored respectively.

[0083] Its usage method is:

[0084] According to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com