Anaerobic ammonium oxidation biochemical treatment method for coking waste water

A technology of anaerobic ammonium oxidation and coking wastewater, which is applied in the field of anaerobic ammonium oxidation biochemical treatment of coking wastewater, can solve the problems that the total nitrogen in the effluent cannot meet the national effluent standard and the operation cost is high, and achieve low infrastructure and operation costs and aeration volume The effect of less, small footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

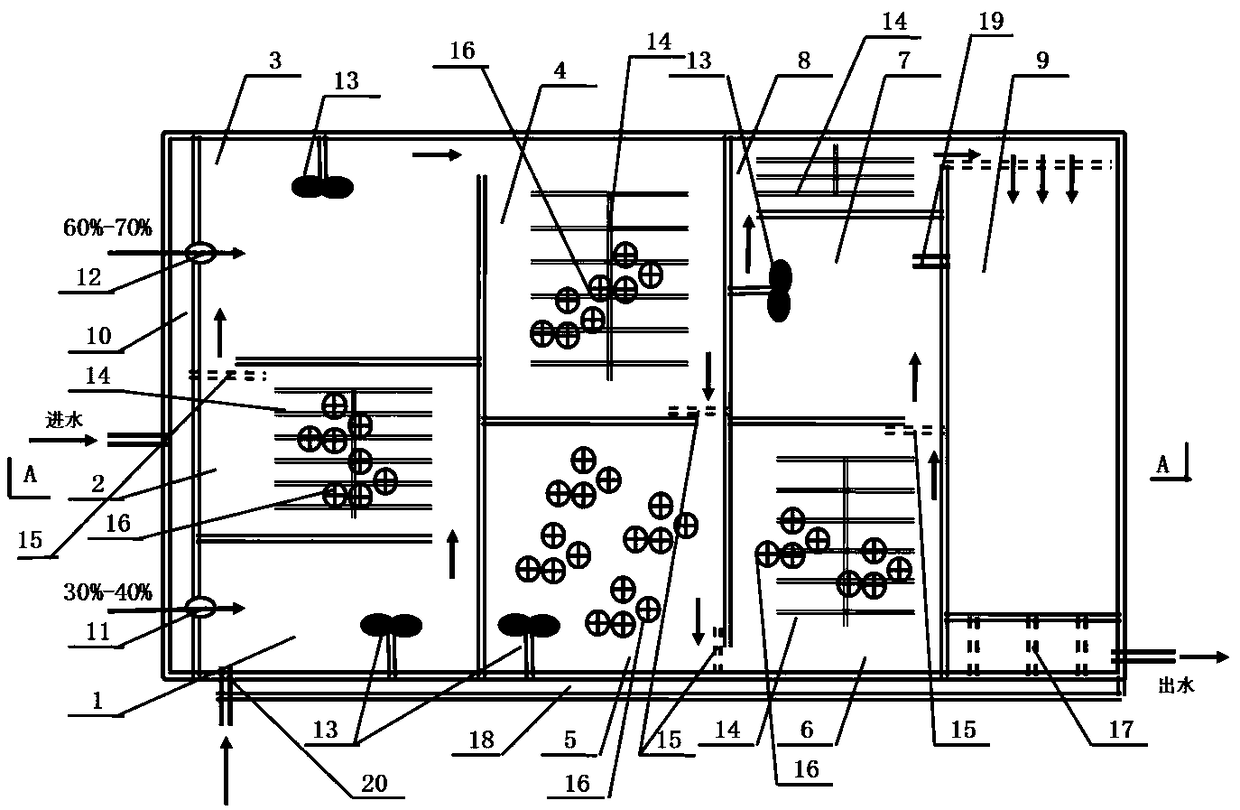

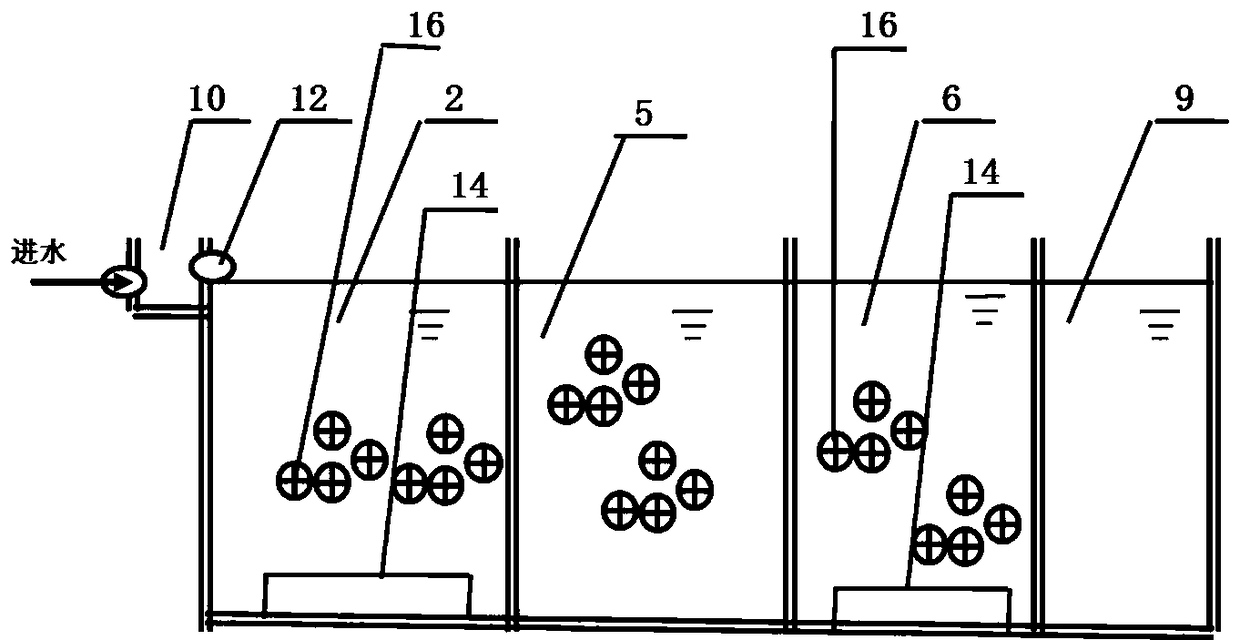

example 1

[0039] In a coking wastewater treatment plant, the influent design water volume is 10000m³ / day, the influent COD concentration is 3500mg / L, BOD concentration is 1000mg / L, NH4-N concentration is 260mg / L, TN position is 300mg / L, TP is 2mg / L. Using the present invention, the added cylindrical suspension carrier is characterized by: the material is HDPE, the specific gravity is 0.95g / cm3, the diameter is 25mm, the height is 10mm, the porosity is ≥88%, the bulk density is ≥100kg / m³, and the effective specific surface area is ≥ 500㎡ / m³; flat screens are used to ensure that suspended carriers do not accumulate on the cross-water section; the HRT in the pre-anoxic zone of the project is 2h, the HRT in the aerobic zone before MBBR is 3h, the HRT in the pre-anoxic zone is 4h, and the MBBR subzone The HRT of the nitrification aerobic zone is 6h, the HRT of the MBBR anaerobic ammonia oxidation zone is 8h, the HRT of the aerobic zone after MBBR is 3h, the HRT of the post-sludge anoxic zone ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com