Modified resin material, and preparation method and usage thereof

A technology of modified resin and reflux reaction, applied in chemical instruments and methods, other chemical processes, improvement of process efficiency, etc., can solve the problems of high price, poor selectivity, low mechanical strength, etc., achieve stable performance, easy separation, The effect of low material cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

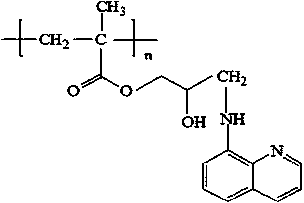

[0024] The modified resin material has a structural formula of:

[0025]

[0026] The preparation method of this modified resin material, its concrete steps are as follows:

[0027] (1) Add polyvinylpyrrolidone to the glycidyl methacrylate solution at a liquid-solid ratio of 3:1ml / g, and then add azobisisobutyronitrile (the solution of which and the glycidyl methacrylate solution solid ratio of 84:1ml / g), and finally add ethanol solution (the liquid-solid ratio of polyvinylpyrrolidone and polyvinylpyrrolidone is 49:1 ml / g), reflux at 60°C for 5h, and separate the liquid and solid, and take out the solid material with a free Washed with water and ethanol, centrifuged and dried in vacuum, the obtained product was labeled as PGMA.

[0028] (2) Add the PGMA obtained in step (1) to the mixed solution of ethanol acetic acid dissolved with 8-aminoquinoline (the solid-to-liquid ratio of PGMA to ethanol solution is 19:1 ml / g, the solid-to-liquid ratio of PGMA to acetic acid solutio...

Embodiment 2

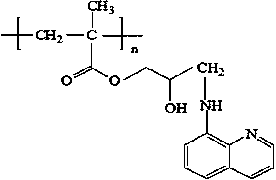

[0032] The modified resin material has a structural formula of:

[0033]

[0034] The preparation method of this modified resin material, its concrete steps are as follows:

[0035] (1) Add polyvinylpyrrolidone to the glycidyl methacrylate solution at a liquid-solid ratio of 3.3:1 ml / g, and then add azobisisobutyronitrile (which is mixed with glycidyl methacrylate solution) The liquid-solid ratio is 84.5:1 ml / g), and finally add ethanol solution (the liquid-solid ratio with polyvinylpyrrolidone is 49.5:1 ml / g), reflux at 70°C for 4 hours, separate the liquid and solid, and take out the solid substance After washing with absolute ethanol and centrifuging, drying in vacuum, the obtained product was labeled as PGMA.

[0036] (2) Add the PGMA obtained in step (1) to the mixed solution of ethanol acetic acid dissolved with 8-aminoquinoline (the solid-to-liquid ratio of PGMA to ethanol solution is 19.5:1 ml / g, the solid-to-liquid ratio of PGMA to acetic acid solution is 1: 2.5 ...

Embodiment 3

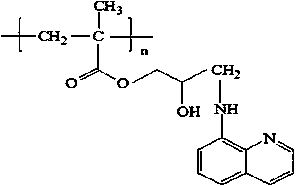

[0040] The modified resin material has a structural formula of:

[0041]

[0042] The preparation method of the modified silicon dioxide nanoparticles, its specific steps are as follows:

[0043] (1) Add polyvinylpyrrolidone to the glycidyl methacrylate solution at a liquid-solid ratio of 3.5:1ml / g, and then add azobisisobutyronitrile (the solution of the glycidyl methacrylate solution) solid ratio of 85:1ml / g), and finally add ethanol solution (the liquid-solid ratio of polyvinylpyrrolidone and polyvinylpyrrolidone is 50:1ml / g), reflux at 75°C for 4.5h, and then separate the liquid and solid, and take out the solid material with free Washed with water and ethanol, centrifuged and dried in vacuum, the obtained product was labeled as PGMA.

[0044] (2) Add the PGMA obtained in step (1) to the mixed solution of ethanol acetic acid dissolved with 8-aminoquinoline (the solid-to-liquid ratio of PGMA to ethanol solution is 20:1 ml / g, the solid-to-liquid ratio of PGMA to acetic a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com