g-C3N4/H-S-TiO2 base nano tube array and preparing method and application thereof

A nanotube array, g-c3n4 technology, which is applied in the field of g-C3N4/H-S-TiO2-based nanotube array and its preparation, can solve the problems such as the limitation of nanotube array performance improvement, improve photoelectric conversion efficiency, and have a wide range of applications , the effect of orderly structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] a g-C 3 N 4 / H-S-TiO 2 A method for preparing a nanotube array, the specific steps are:

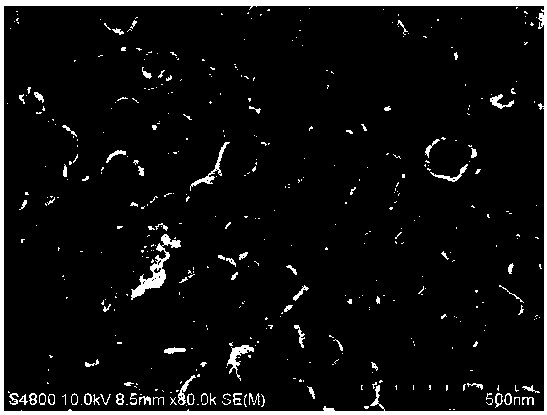

[0041] A titanium sheet with a thickness of 0.2 mm was selected, ultrasonically cleaned in deionized water, acetone, isopropanol, and absolute ethanol for 3 minutes each, and dried in a drying oven for later use. Select the electrolyte, specifically 0.5wt%NH 4 F+0.3MH 3 PO 4 Electrochemical anodic oxidation of metal titanium in the electrolyte system at 20V for 1 hour, and a highly ordered ordered array of nanotubes grow on the surface of metal titanium, with an average diameter of nanotubes of about 100nm and a wall thickness of 12nm , tube length 650nm.

[0042] The ordered array of nanotubes was first heat-treated at 500°C for 2 hours, and then treated at 550°C for 1-3 hours in a certain closed hydrogen sulfide atmosphere, and the heating rate was 3°C / min to obtain H-S-TiO 2 base nanotube arrays.

[0043] Weigh a certain amount of urea, and heat-treat the urea in a muff...

Embodiment 2

[0045] a g-C 3 N 4 / H-S-TiO 2 A method for preparing a nanotube array, the specific steps are:

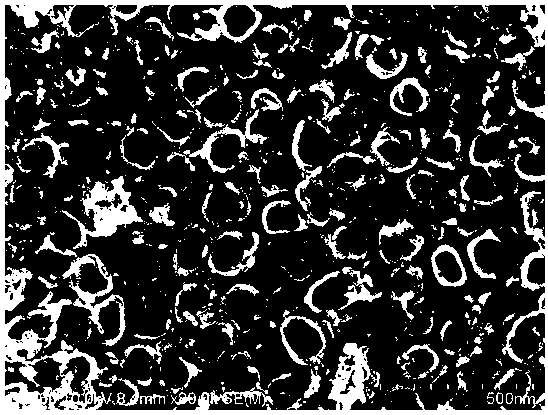

[0046] A 0.2 mm thick pure titanium sheet was selected, polished brightly with coarse and fine sandpaper, ultrasonically cleaned with deionized water, acetone, isopropanol, and absolute ethanol for 3 minutes, and dried in a drying oven for later use. Select the electrolyte, specifically 0.5wt%NH 4 F+0.1MH 3 PO 4 Electrochemical anodic oxidation of metal titanium in the electrolyte system at 20V for 1h, and a highly ordered ordered array of nanotubes grow on the surface of metal titanium, with an average diameter of nanotubes of about 90nm and a wall thickness of 15nm , tube length 600nm.

[0047] The ordered array of nanotubes was first heat-treated at 500°C for 2h, and then treated at 550°C for 3h in a certain closed hydrogen sulfide atmosphere, and the heating rate was 3°C / min to obtain H-S-TiO 2 base nanotube arrays.

[0048] Measure 5g of urea and 50ml of absolute etha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| verticality | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com