A kind of soy sauce brewing system and its application in brewing soy sauce

A technology for brewing soy sauce and soy sauce, which is applied in the soy sauce brewing system and its application field in brewing soy sauce, can solve the problems of soy sauce taste, aroma and physical and chemical indicators are very different, the drying tank cannot be dried, and the land utilization rate is low. Achieve the effects of delicious taste, improved aroma components and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

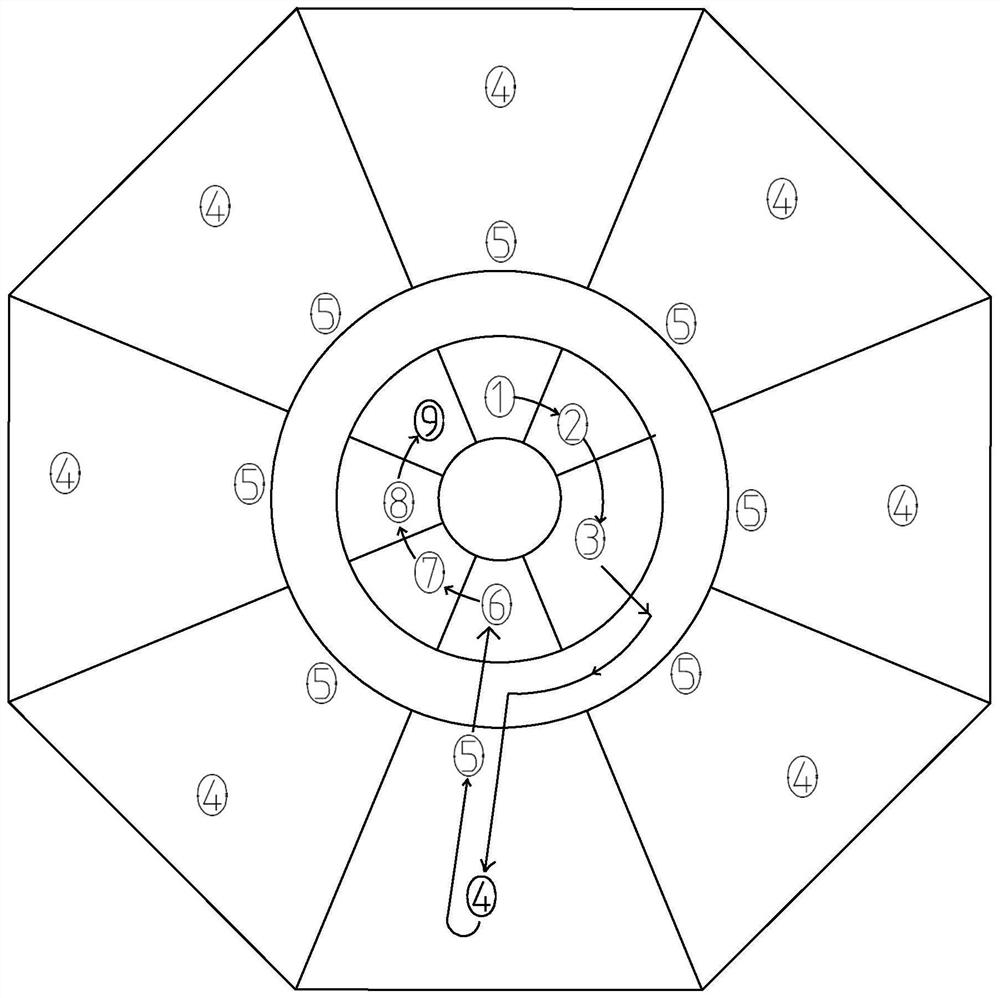

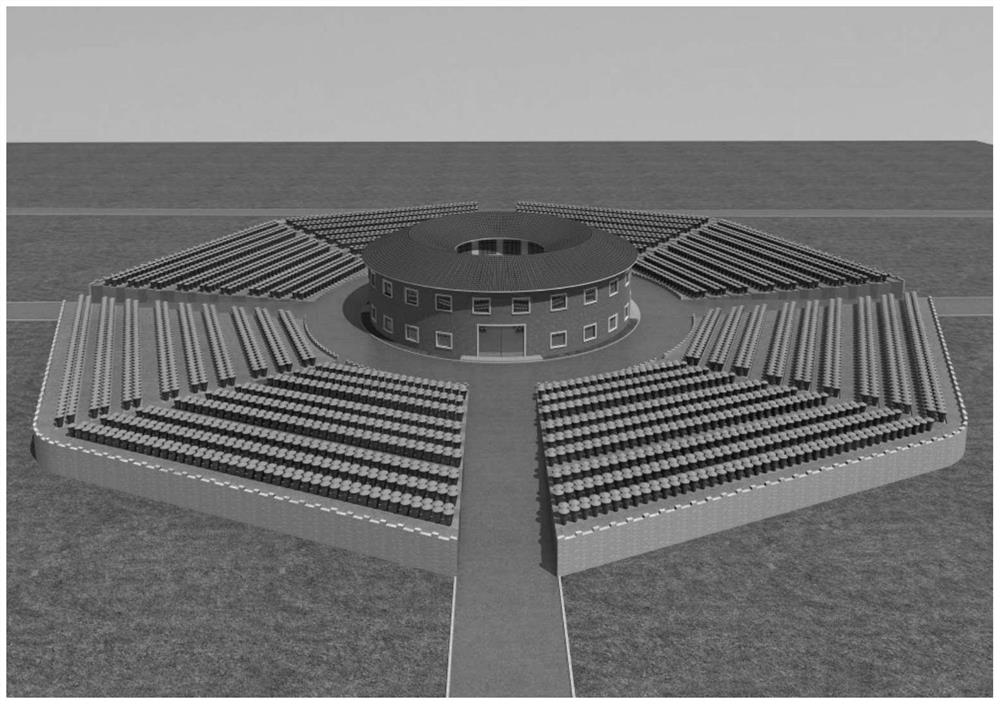

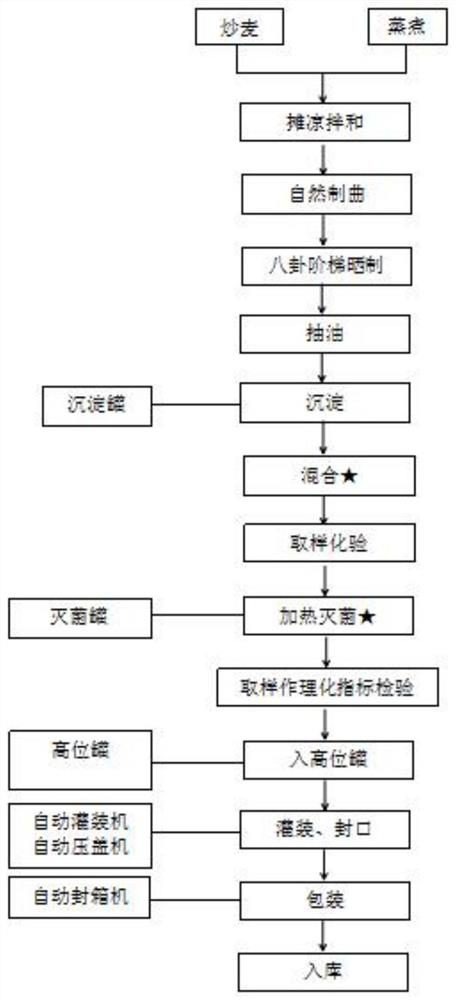

Method used

Image

Examples

Embodiment 1

[0057] The wheat accounting for 10% of the total raw material weight is removed and then roasted, cooled after being taken out of the pan, and crushed into flour for later use;

[0058] Soybeans accounting for 22.5% of the total raw material weight were rinsed and soaked for 3 hours, then put into a wooden steamer and steamed for 4 hours;

[0059] Add the soybeans cooled to 35°C to the cooked flour and mix evenly, put them into the bamboo dustpan and spread them evenly, place them on the wooden shelf in the koji room, use the beneficial bacteria such as Aspergillus oryzae that grow naturally in the koji room as the seed koji, The room temperature is controlled at about 35°C. After about 48 hours, the soybean material grows white mycelium, and then keeps warm for 5 days. After the white mycelium gradually turns green and yellow, the koji making is completed;

[0060] Add water accounting for 52.5% of the total raw material weight and salt accounting for 15% of the total raw mat...

experiment example 1

[0066] Determination of aroma components: Except for different raw materials, the rest of the operations are exactly the same.

[0067] Take 8mL of soy sauce and put it into a 20mL gas cylinder and add 1g of sodium chloride to make the salt concentration reach saturation. in the test sample. After being incubated at 45°C for 20 minutes, the soy sauce sample was extracted for 40 minutes at 45°C with the CAR / PDMS extraction head. After the extraction was completed, the extraction head was inserted into the injection port for analysis for 3 minutes. The extraction head was aged at 270 °C for 1 h before each use, and the extraction head was aged at 270 °C for 10 min between each sample to prevent contamination.

[0068] Chromatographic column: TR-5MS elastic quartz capillary chromatographic column (30m×0.25mm×0.25μm). The initial temperature is 40°C, keep for 2min, rise to 120°C at 4°C / min, keep for 2min, then rise to 280°C at 10°C / min, keep for 5min; carrier gas: high-purity he...

experiment example 2

[0075] The composition of amino acids in soy sauce was analyzed by conventional high-performance liquid chromatography pre-column derivatization method, and the results are shown in Table 2.

[0076] Amino acid content in table 2 soy sauce

[0077] amino acid Content (unit: g / 100ml) aspartic acid 0.896 glutamic acid 1.748 threonine 0.382 serine 0.435 Glycine 0.398 Alanine 0.412 proline 0.396 Phenylalanine 0.451 Lysine 0.695 arginine 0.439

[0078] It can be seen that the soy sauce brewed by this method contains 8 kinds of amino acids such as lysine, threonine, methionine, and arginine necessary for human body, and has a strong aroma. Among them, glutamic acid and aspartame are the main sources of umami. amino acids, accounting for 30% of the total amino acids; serine, glycine, alanine and proline, which are the source of sweetness in soy sauce, accounted for 18% of the total amino acids; 5% of the tot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com