Method for recovering chloromethane from byproduct hydrochloric acid and recovery device

A technology of by-product hydrochloric acid and methyl chloride, which is applied in the field of recycling technology, can solve the problems of complex processing process, high processing cost, unfavorable industrial scale use, etc., and achieve the effect of reducing VOC content, simple analysis process, and reducing equipment material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

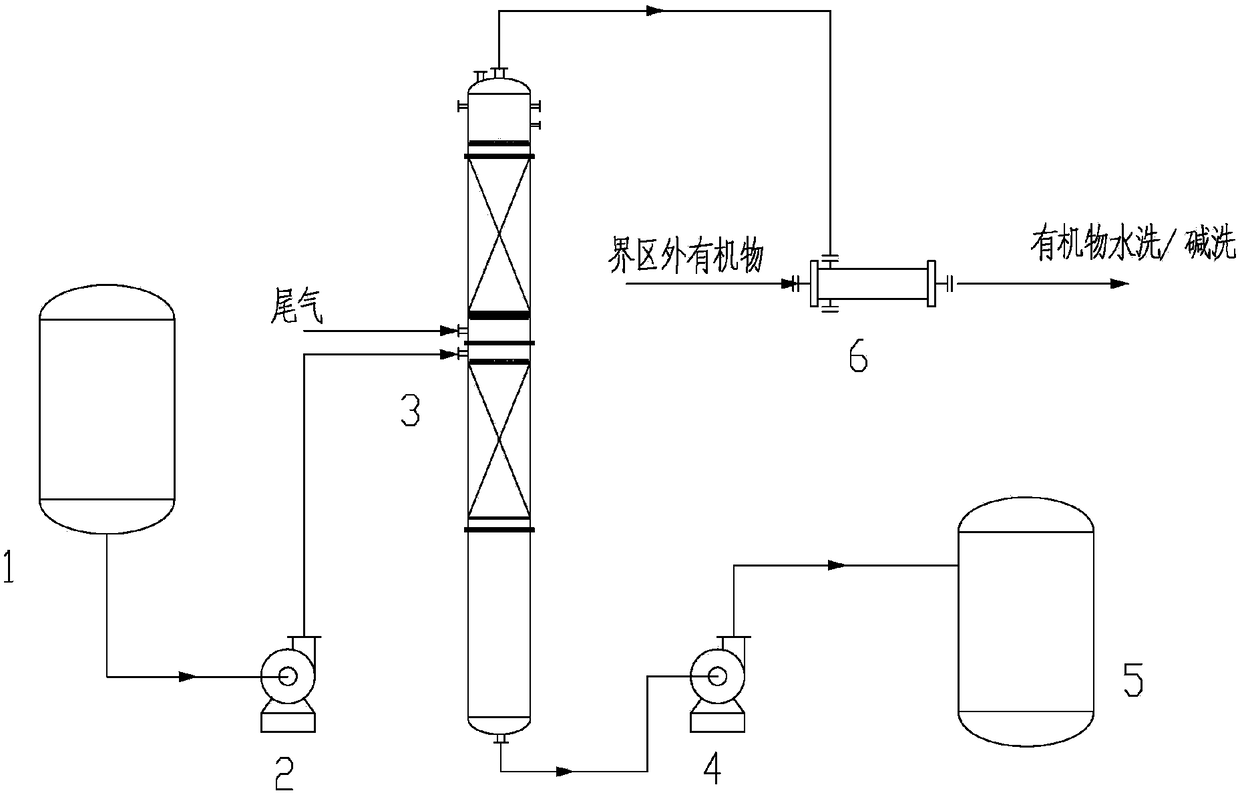

[0039] A device for recovering methyl chloride from by-product hydrochloric acid, the structure is as follows figure 1 As shown, the device includes an analytical tower 3, which includes a tower body, the tower body is a vertical structure, the top of the tower body is provided with a gas outlet, the bottom of the tower body is provided with a liquid outlet, and the tower body is provided with a liquid feed inlet and The gas feed port, from top to bottom in the tower body, consists of a gas zone, an analysis zone and a liquid zone in sequence, and the analysis zone is filled with fillers; the liquid feed port is connected to the by-product hydrochloric acid buffer tank 1 through the feed pump 2, and the liquid outlet passes through The discharge pump 4 is connected with the hydrochloric acid storage tank 5, and the gas outlet is connected with the mixer 6 through a pipeline.

[0040] The height of the analysis area accounts for 1 / 2 of the height of the tower body, and the pack...

Embodiment 2

[0047] Utilize the device of embodiment 1 to reclaim the methyl chloride method from by-product hydrochloric acid, may further comprise the steps:

[0048] (1) the by-product hydrochloric acid (chloromethane content 2.25%) that concentration is 24% utilizes feed pump to pass into from the liquid feed inlet of desorption tower with the flow velocity of 1.12 tons / hour, and the feed temperature of by-product hydrochloric acid is 55 ℃ ℃; the mixed gas of hydrogen chloride and methyl chloride enters from the gas inlet, and the feeding amount is 0.5m 3 / h, wherein the volume ratio of methyl chloride is 6.0%.

[0049] (2) The by-product hydrochloric acid enters the analysis area through the liquid distributor to absorb hydrogen chloride in the tail gas. The analysis tower uses the reboiler at the bottom of the tower to provide the heat source; the reboiler heats the tower body to keep the temperature of the tower body at 65 ° C. The pressure is 28KPa; after analysis, the volume rati...

Embodiment 3

[0052] Utilize the device of embodiment 1 to reclaim the methyl chloride method from by-product hydrochloric acid, may further comprise the steps:

[0053] (1) the by-product hydrochloric acid (chloromethane content 1.56%) that concentration is 20% utilizes desorption tower feed pump to pass into from the liquid feed inlet of desorption tower with the flow velocity of 1.4 tons / hour, the feed temperature of by-product hydrochloric acid The temperature is 50°C; the mixed gas of hydrogen chloride and methyl chloride enters from the gas feed port, and the feed amount is 0.5m 3 / h, wherein the volume ratio of methyl chloride is 5.4%.

[0054] (2) The by-product hydrochloric acid enters the analysis area through the liquid distributor to absorb hydrogen chloride in the tail gas. The analysis tower uses the reboiler at the bottom of the tower to provide the heat source; the reboiler heats the tower body to keep the temperature of the tower body at 80 ° C. The pressure is 32KPa; afte...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com