Preparation method of hemicellulose phenyl carbonate

A technology of phenyl carbonate and hemicellulose, which is applied in the field of preparation of hemicellulose phenyl carbonate, can solve the problems of the yield of hemicellulose easily degradable products, the low degree of product substitution, the generation of by-products, etc. High yield, single product and controllable degree of substitution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Weigh 9g of 1-allyl-3-methylimidazole chloride in a 50mL three-neck flask, dissolve in an oil bath at 80°C, add 1g of xylan, stir magnetically for 2 hours until completely dissolved; cool the above xylan / ionic liquid to At room temperature, add 10 mL of pyridine, stir at room temperature for 0.5 h; slowly add 5.81 mL of phenyl chloroformate, and react at room temperature for 1 h; After washing 5 times, vacuum drying at 40°C for 24 hours, xylan phenyl carbonate was obtained with a yield of 78.4% and a degree of substitution of 2.0. The reaction scheme was as follows:

[0036]

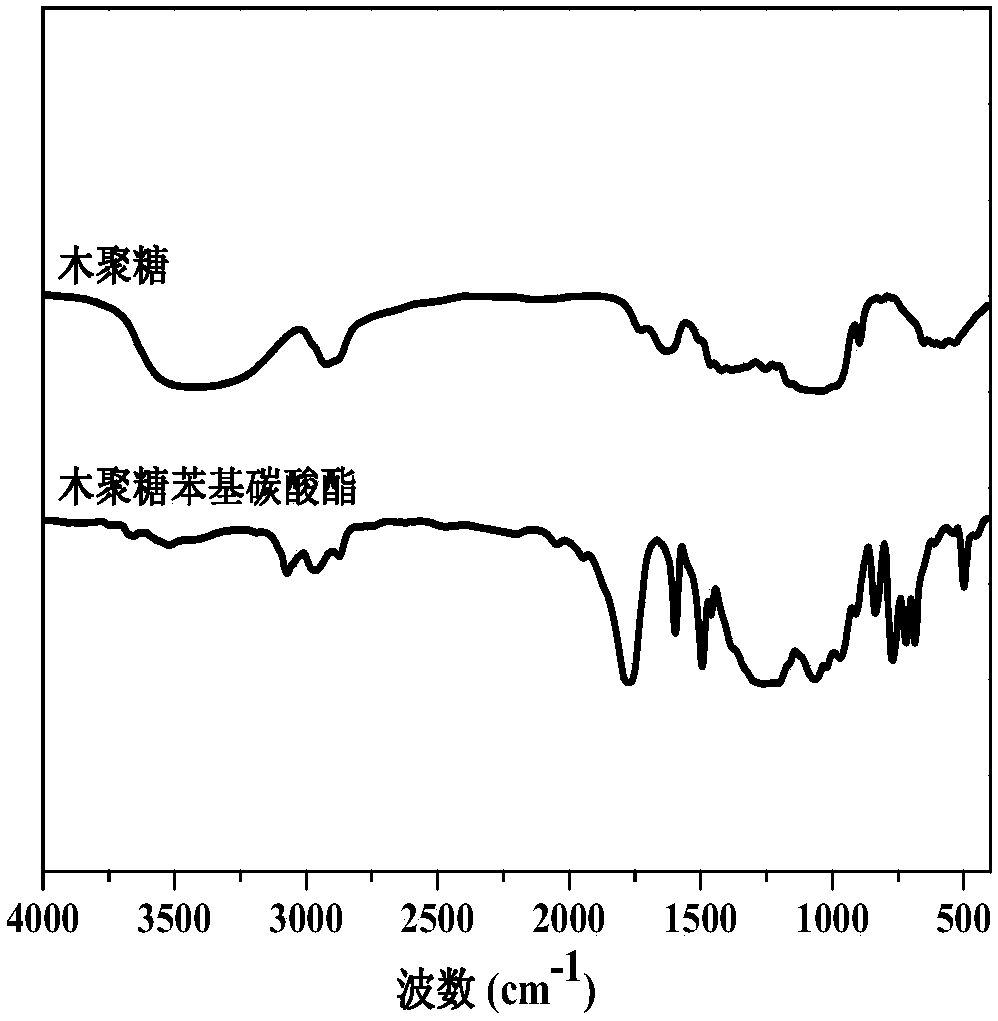

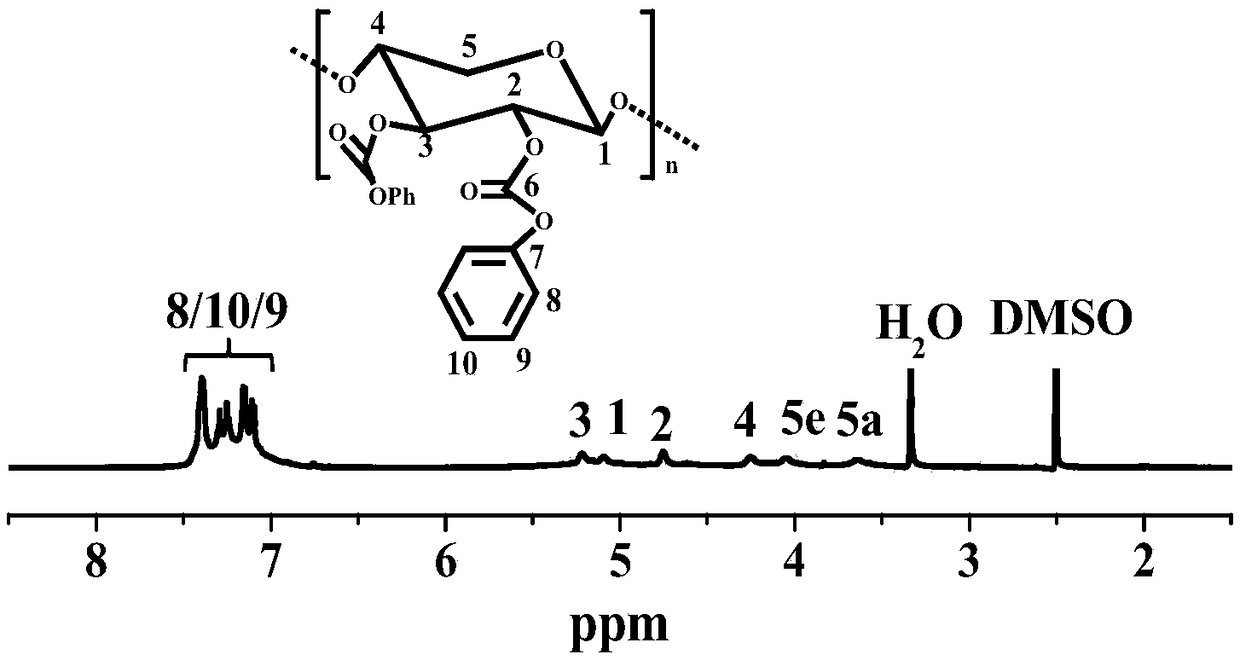

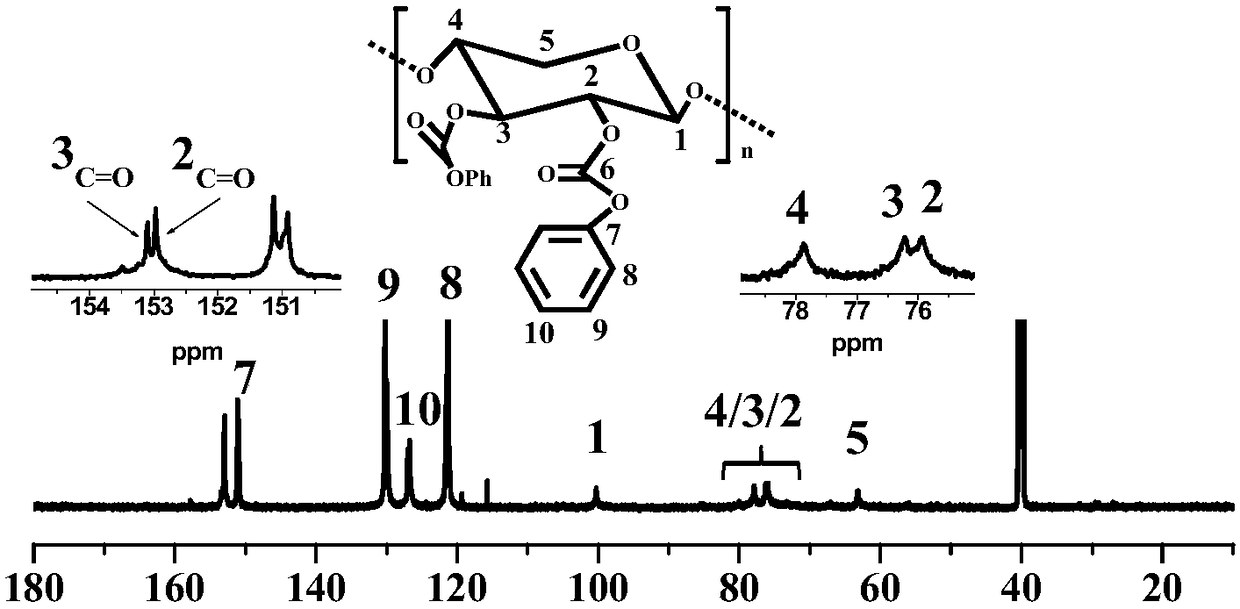

[0037] Identification of xylan phenyl carbonate: the FT-IR spectrograms of xylan and xylan phenyl carbonate in this embodiment are respectively as follows figure 1 In a, b shown, by figure 1 It can be known from the b in 1770cm -1 The C=O stretching vibration peak in the ester bond appears at 3070cm -1 and 832cm -1 are the C-H stretching and bending vibration peaks on the benzene ring respe...

Embodiment 2

[0043] Weigh 9g of 1-allyl-3-methylimidazole chloride into a 50mL three-neck flask, dissolve in an oil bath at 80°C, add 1g of xylan, stir magnetically for 2 hours until completely dissolved; cool the above xylan / ionic liquid to At room temperature, add 10mL of pyridine, stir at room temperature for 0.5h; slowly add 0.83mL of phenyl chloroformate, and react at room temperature for 1h; after the reaction, use methanol to precipitate, collect the precipitate and continue to use methanol to wash 5 times, and vacuum dry at 40°C for 24h , to obtain xylan phenyl carbonate with a yield of 71.9% and a degree of substitution of 0.2. The FT-IR spectrogram of xylan and xylan phenyl carbonate in the present embodiment is as Figure 5 shown.

Embodiment 3

[0045] Weigh 9g of 1-allyl-3-methylimidazole chloride into a 50mL three-neck flask, dissolve in an oil bath at 80°C, add 1g of xylan, stir magnetically for 2 hours until completely dissolved; cool the above xylan / ionic liquid to At room temperature, add 10mL of pyridine, stir at room temperature for 0.5h; slowly add 3.32mL of phenyl chloroformate, and react at room temperature for 1h; after the reaction, use methanol to precipitate, collect the precipitate and continue to use methanol to wash 5 times, and vacuum dry at 40°C for 24h , to obtain xylan phenyl carbonate with a yield of 76.2% and a degree of substitution of 1.6. The FT-IR spectrogram of xylan and xylan phenyl carbonate in the present embodiment is as Figure 6 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com