Methyleugenol molecularly imprinted polymer and preparation method thereof

A technology of methyl eugenol and polymer, which is applied in the field of separation material synthesis of natural products or biologically active components, can solve the problems of unreported methyl eugenol purification method, unreported preparation method, unsatisfactory removal effect and the like , to achieve the effect of strong selectivity, simple regeneration method and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Weigh 2.0g of methyl eugenol and 2.9g of methacrylic acid into a conical flask for mixing, then add 100ml of dichloromethane, mix the mixture thoroughly by ultrasonication for 15min, and then let it stand for 1h.

[0030] 2) Weigh 22.3g of ethylene glycol dimethacrylate and 0.3g of azobisisobutyronitrile into the above Erlenmeyer flask, mix ultrasonically for 10min, blow with nitrogen for 15min to remove oxygen, seal it, and polymerize in a constant temperature oscillating water bath at 60°C for 24h Obtain a white solid polymer, take out the polymer, and pass through a 100-mesh sieve after grinding.

[0031] 3) The above-mentioned polymer was first eluted by Soxhlet elution for 15h, and the eluent was 200ml of methanol-acetic acid mixed solution with a volume ratio of 9:1, and then eluted with 100ml of methanol for 8h.

[0032] 4) Then eluted with 200ml of methanol, then eluted with 200ml of water, and finally dried at 60°C.

[0033] 5) The preparation method of the...

Embodiment 2

[0035] 1) Weigh 2.0g of methyl eugenol and 7.7g of methacrylic acid into a conical flask for mixing, then add 300ml of dichloromethane, ultrasonicate the mixture for 15min to make it fully mixed, and then let it stand for 1h.

[0036] 2) Weigh 66.8g of ethylene glycol dimethacrylate and 0.8g of azobisisobutyronitrile into the above Erlenmeyer flask, mix ultrasonically for 10min, blow with nitrogen for 15min to remove oxygen, seal it, and polymerize in a constant temperature oscillating water bath at 65°C for 24h Obtain a white solid polymer, take out the polymer, and pass through a 100-mesh sieve after grinding.

[0037] 3) The above-mentioned polymer was first eluted by Soxhlet elution for 15h, and the eluent was 500ml of methanol-acetic acid mixed solution with a volume ratio of 9:1, and then eluted with 300ml of methanol for 8h.

[0038] 4) Then eluted with 500ml of methanol, then eluted with 500ml of water, and finally dried at 60°C.

[0039] 5) The preparation method of ...

Embodiment 3

[0041] 1) Weigh 2.0g of methyl eugenol and 5.9g of methacrylic acid into a conical flask for mixing, then add 200ml of dichloromethane, ultrasonicate the mixture for 15min to make it fully mixed, and then let it stand for 1h.

[0042] 2) Weigh 46.5g of ethylene glycol dimethacrylate and 0.45g of azobisisobutyronitrile into the above-mentioned Erlenmeyer flask, mix ultrasonically for 10min, blow with nitrogen for 15min to remove oxygen, seal it, and polymerize in a constant temperature oscillating water bath at 65°C for 36h Obtain a white solid polymer, take out the polymer, and pass through a 100-mesh sieve after grinding.

[0043]3) The above-mentioned polymer was first eluted by Soxhlet elution method for 15h, and the eluent was 300ml methanol-acetic acid mixed solution with a volume ratio of 9:1, and then eluted with 200ml methanol Soxhlet for 8h.

[0044] 4) Then eluted with 300ml of methanol, then eluted with 400ml of water, and finally dried at 60°C.

[0045] 5) The pre...

PUM

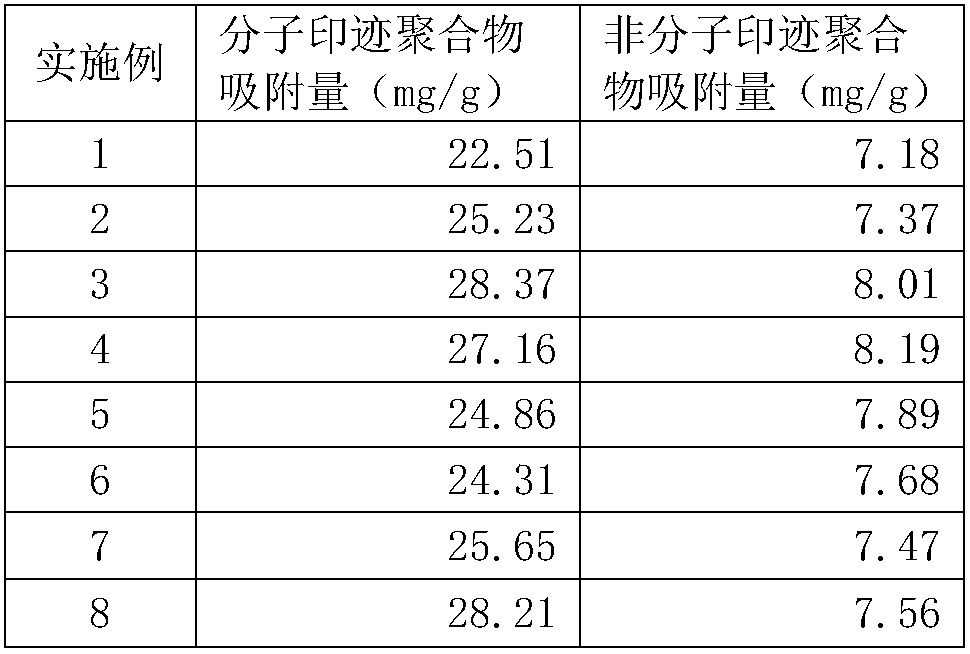

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com