Preparation method of biodegradable agricultural mulching film

A technology of agricultural mulch and biodegradation, applied in botany equipment and methods, applications, plant protection, etc., can solve the problems of long plastic mulch degradation time, crop yield reduction, soil pollution, etc., to improve biodegradability and help Effect on reproduction and growth, improving porosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

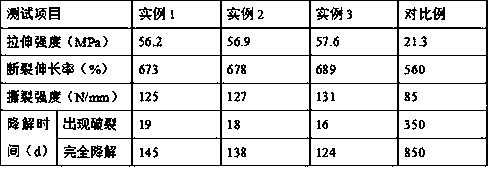

Examples

example 1

[0026]According to the mass ratio of 1:5, mix rice straw and 7% sodium hydroxide solution in a blender, heat and boil at 70°C for 30 minutes, then add 85mL of 32% hydrogen peroxide, and continue the heat preservation reaction 1h, filter and separate to obtain the rice straw filter residue, in parts by weight, add 40 parts of rice straw filter residue, 30 parts of biogas slurry and 9 parts of sucrose to the fermenter, mix and stir for 8 minutes, then seal and ferment at 35°C for 6 days, Filter to obtain a filter cake, wash the filter cake 4 times with deionized water, and transport it to the crop straw fiber making machine, and make the self-made rice straw fiber at a speed of 2000r / min. The mass ratio is 5:1. Mix self-made rice straw fiber and titanate coupling agent KR-9S in a blender, and stir at 40°C for 1 hour to obtain modified rice straw fiber. Weigh 30 g of polyvinyl alcohol and add it to 60 mL of deionized water. After dissolving at ℃ for 12min, place it in a magnetic ...

example 2

[0028] According to the mass ratio of 1:5, mix rice straw and 7% sodium hydroxide solution in a blender, heat and boil at 75°C for 35 minutes, then add 95mL of 32% hydrogen peroxide, and continue the heat preservation reaction 1.5h, filter and separate to obtain the rice straw filter residue, in parts by weight, add 50 parts of rice straw filter residue, 40 parts of biogas slurry and 10 parts of sucrose to the fermenter, mix and stir for 9 minutes, then seal and ferment at 40°C for 8 days , filter to obtain a filter cake, and wash the filter cake with deionized water for 5 times, and transport it to the crop straw fiber making machine, and make the self-made rice straw fiber at a speed of 2200r / min, and the mass ratio is 5:1 Mix self-made rice straw fiber and titanate coupling agent KR-9S in a blender, stir at 50°C for 1.5 hours to obtain modified rice straw fiber, weigh 35g of polyvinyl alcohol and add it to 70mL of deionized water, After dissolving at 55°C for 14min, place i...

example 3

[0030] According to the mass ratio of 1:5, mix rice straw and 7% sodium hydroxide solution in a blender, heat and cook at 80°C for 40 minutes, then add 105mL of 32% hydrogen peroxide, and continue the heat preservation reaction 2h, filter and separate to obtain the rice straw filter residue, in parts by weight, add 60 parts of rice straw filter residue, 50 parts of biogas slurry and 11 parts of sucrose to the fermenter successively, mix and stir for 10 minutes, then seal and ferment at 45°C for 9 days, Filter to obtain a filter cake, wash the filter cake with deionized water for 6 times, and transport it to the crop straw fiber making machine, and make the self-made rice straw fiber at a speed of 2400r / min. The mass ratio is 5:1. Mix self-made rice straw fiber and titanate coupling agent KR-9S in a mixer, stir at 60°C for 2 hours to obtain modified rice straw fiber, weigh 40g of polyvinyl alcohol and add it to 80mL of deionized water, at 65 After dissolving at ℃ for 16min, pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com