Preparation method of vanadium pentoxide film and application thereof

A vanadium pentoxide and thin-film technology, which is used in semiconductor/solid-state device manufacturing, photovoltaic power generation, electrical components, etc. Ultra-high, low-cost effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Embodiment 1, the preparation of vanadium pentoxide film

[0028] Take 30mg of ammonium metavanadate NH 4 VO 3 Place in 3mL of a mixed solution of ethylene glycol and dimethyl sulfoxide (the volume ratio of ethylene glycol and dimethyl sulfoxide is 2:1), and heat to dissolve at 80°C to form a transparent golden yellow solution, and then put the After the solution was naturally cooled to room temperature, 80uL of the solution was spin-coated on the cleaned ITO conductive glass at a spin-coating speed of 3500rpm / min for 60s. After spin coating, put the film on a heating plate, and heat it at 200° C. for 45 minutes to obtain the vanadium pentoxide thin film of the present invention.

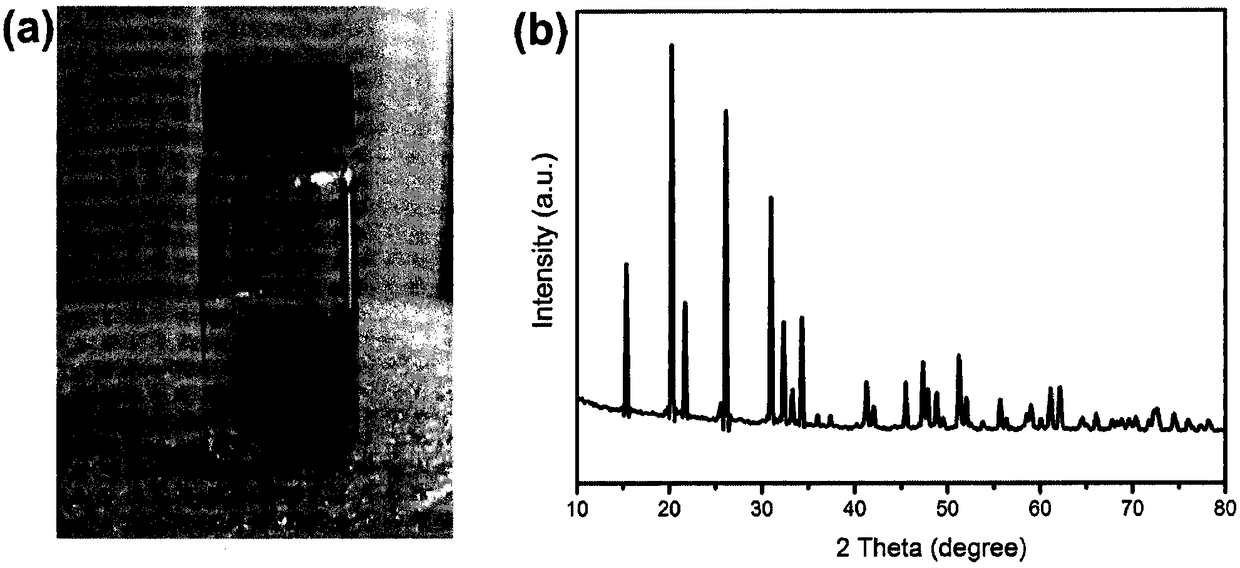

[0029] The characterization of vanadium pentoxide film of the present invention: figure 1 (a) is the vanadium pentoxide precursor solution of 10mg / mL; Analyze and determine the structure of vanadium pentoxide film with X-ray diffractometer, the result is as follows figure 1 (b), shown by ...

Embodiment 2

[0031] Embodiment 2, prepare CH on the vanadium pentoxide film 3 NH 3 PB 3 film

[0032] Dissolve methyl iodide and lead iodide in 1 mL of mixed solution DMF and DMSO (volume ratio 4:1) to prepare CH 3 NH 3 PB 3 Precursor solution, get this solution 70uL and add drop-wise on the vanadium pentoxide thin film prepared in embodiment 1 and carry out spin-coating, wherein spin-coating rotating speed 4500rpm / min, spin-coating time 30s, drip 400uL chlorobenzene in spin-coating, then Heating on a heating plate at 80°C for 10 min, cooling to produce CH 3 NH 3 PB 3 film, the CH 3 NH 3 PB 3 The films were examined by scanning electron microscopy (SEM). image 3 (a) see CH 3 NH 3 PB 3 The grain size of the film spin-coated on ITO is about 200nm, and CH can be seen in (b) 3 NH 3 PB 3 The grain size on which the films were spin-coated was generally greater than 1 um.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com