Efficient domestic sewage filter plate and preparation method thereof

A domestic sewage and filter plate technology, which is applied in the direction of filtration separation, filtration treatment, separation methods, etc., can solve the problems of affecting the treatment efficiency of domestic sewage, poor filtration efficiency, and difficulty in cleaning, etc., and achieve high sewage filtration effect, reduce costs, and reduce effect of difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

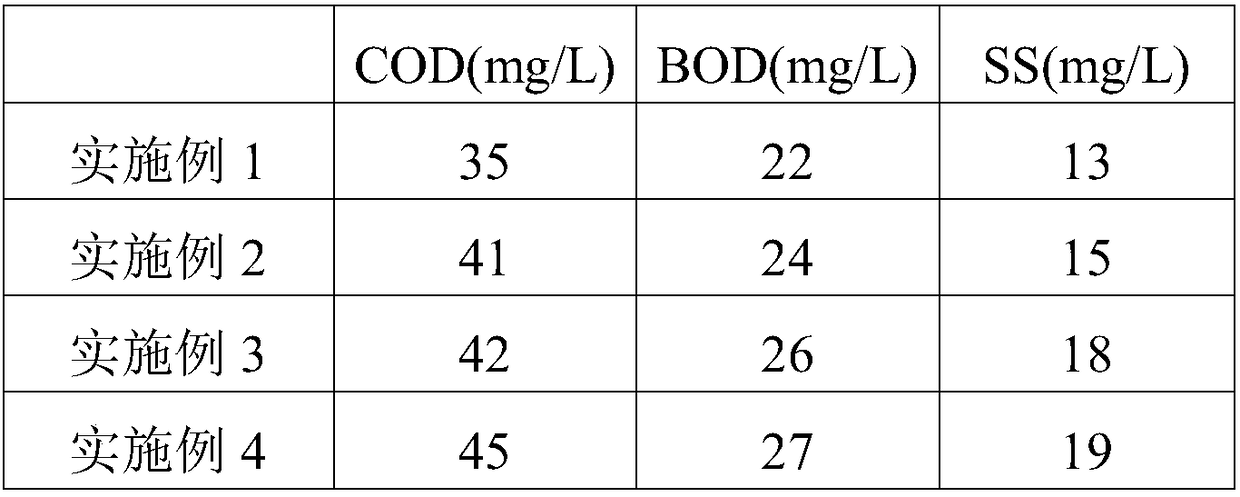

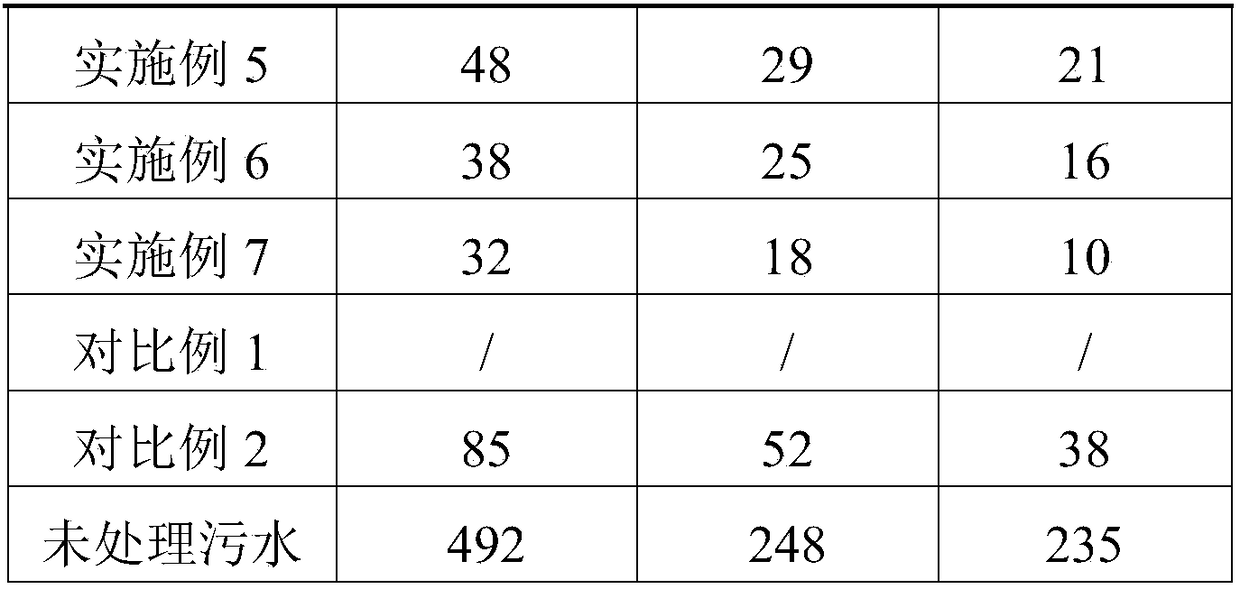

Examples

preparation example Construction

[0036] The present invention also provides a method for preparing the above-mentioned high-efficiency domestic sewage filter plate, comprising the following steps:

[0037] (1) Take kaolin, high-alumina vanadium clay, glass powder, zinc salt, magnesium salt, nickel salt according to the formula quantity, put into a high-speed mixer and fully mix to obtain mixture A;

[0038] (2) Transfer the mixture A in step (1) into a stirring container, add a solvent, stir and mix, then put in surfactants, organotitanates, silane coupling agents, reinforcing fibers and tackifiers to obtain mixture B ;

[0039] (3) Put the mixture B into a plate-shaped mold for pressing and molding, then transfer it to a high-temperature calciner, calcinate at a high temperature of 550-680°C, and obtain the domestic sewage filter plate after cooling.

[0040] In order to optimize the pore structure of the filter plate, the calcination process in the step (3) of the present invention is divided into two time...

Embodiment 1

[0043] A high-efficiency domestic sewage filter plate, the filter plate is prepared from a raw material composition, and the raw material composition includes the following materials in parts by weight: 100 parts of kaolin, 22 parts of high alumina bauxite, and 20 parts of glass powder , 6 parts of zinc chloride, 6 parts of magnesium chloride, 6 parts of nickel chloride, 10 parts of surfactant sodium lauryl alcohol polyoxyethylene ether sulfate, 22 parts of n-butyl titanate, 8 parts of vinyl trichlorosilane, 11 parts of alkali-free glass fiber, 5 parts of hydroxymethyl cellulose, 420 parts of acetone;

[0044] The preparation method of above-mentioned domestic sewage filter plate comprises:

[0045] (1) Take kaolin, high alumina vanadium clay, glass powder, zinc chloride, magnesium chloride, nickel chloride according to the formula quantity, put into high-speed mixer and fully mix to obtain mixture A;

[0046] (2) Transfer the mixture A in step (1) into a stirring container, ...

Embodiment 2

[0049] A high-efficiency domestic sewage filter plate, the filter plate is prepared from a raw material composition, and the raw material composition includes the following materials in parts by weight: 100 parts of kaolin, 18 parts of high alumina bauxite, and 15 parts of glass powder , 5 parts of zinc chloride, 5 parts of magnesium chloride, 5 parts of nickel chloride, 8 parts of surfactant sodium lauryl alcohol polyoxyethylene ether sulfate, 18 parts of n-butyl titanate, 7 parts of vinyl trichlorosilane, 9 parts of alkali-free glass fiber, 4 parts of hydroxymethyl cellulose, 400 parts of acetone;

[0050] The preparation method of above-mentioned domestic sewage filter plate comprises:

[0051] (1) Take kaolin, high alumina vanadium clay, glass powder, zinc chloride, magnesium chloride, nickel chloride according to the formula quantity, put into high-speed mixer and fully mix to obtain mixture A;

[0052] (2) Transfer the mixture A in step (1) into a stirring container, ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com