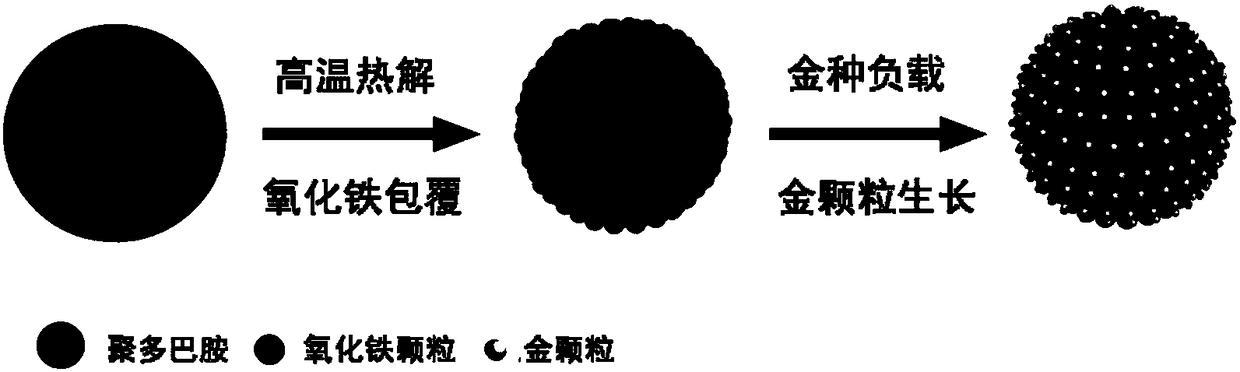

Superparamagnetism-plasma composite microsphere and preparation method thereof

A plasma and composite microsphere technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of complex preparation process, nano-templates without metal affinity, and low particle coating density. , to achieve and tune the plasmonic optical effect, the excellent plasmonic optical effect, and the simple and easy preparation method.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] (1) Measure 40mL of ethanol, 90mL of ultrapure water and 2.2mL of ammonia water, and pour them into a 250mL reaction bottle. Weigh 0.5 g of dopamine hydrochloride and dissolve it in 10 mL of water, quickly add it into the above mixed solution under vigorous stirring, and magnetically stir at room temperature for 30 h. The solution was centrifuged to collect the precipitate and washed several times with water to obtain 100 nm polydopamine microspheres.

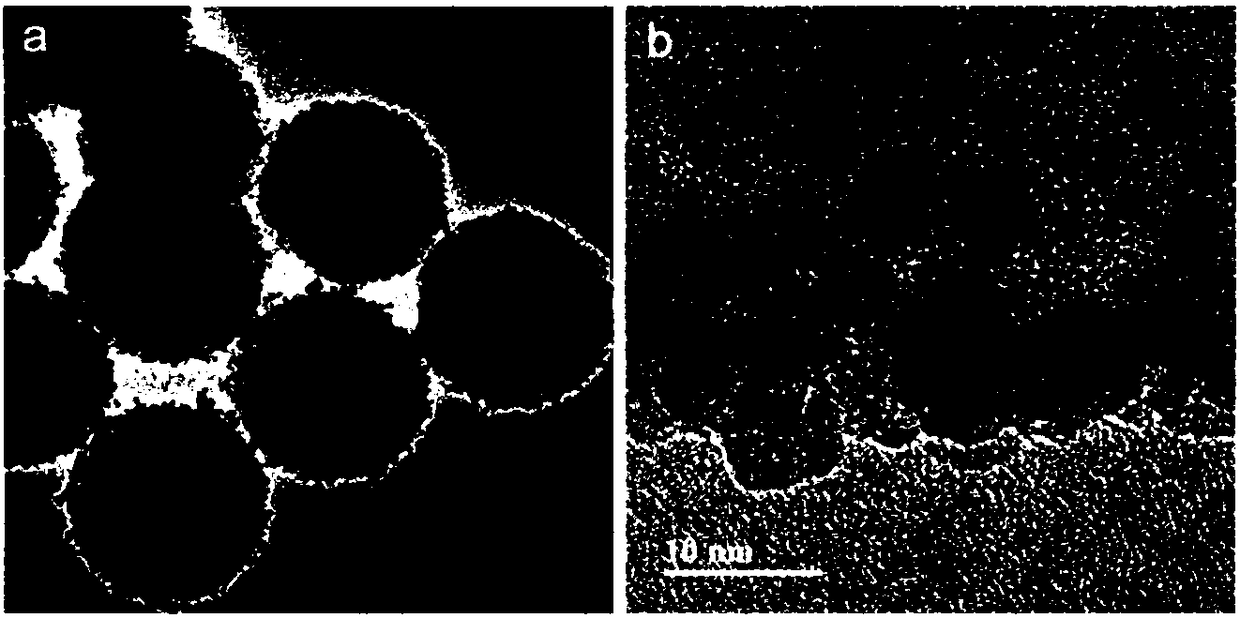

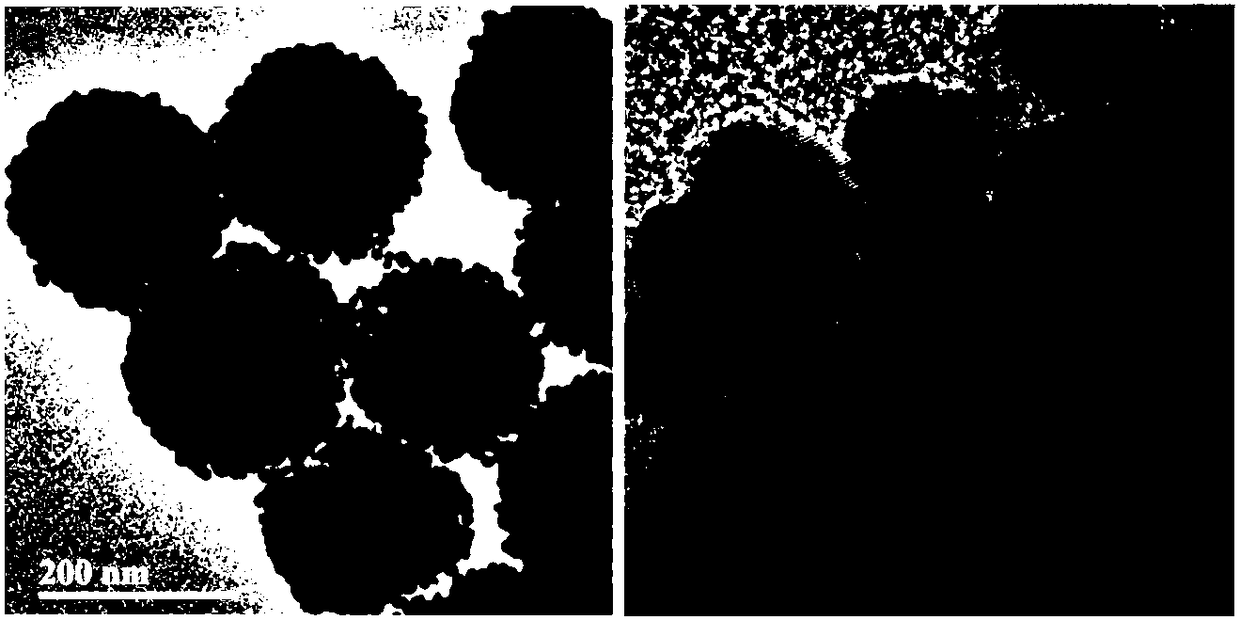

[0057] (2) Polydopamine microspheres (about 50 mg in dry weight) were dissolved in 0.5 mL of ethanol and added to a 50 mL two-necked reaction flask. Then 120 mg of iron acetylacetonate and 10 mL of triethylene glycol were added. The temperature of the solution was raised to 70 °C under vacuum and maintained for more than 15 min to remove ethanol. After filling the bottle with nitrogen or argon, the temperature was raised to 210° C. and magnetically stirred for 2 h; under the inert gas atmosphere, the temperature was ra...

Embodiment 2

[0062] (1) Measure 40mL of ethanol, 90mL of ultrapure water and 0.68mL of ammonia water, and pour them into a 250mL reaction bottle. Weigh 0.5 g of dopamine hydrochloride and dissolve it in 10 mL of water, quickly add it into the above mixed solution under vigorous stirring, and magnetically stir at room temperature for 30 h. The solution was centrifuged to collect the precipitate and washed several times with water to obtain 370nm polydopamine microspheres;

[0063] (2) Polydopamine microspheres (about 50 mg in dry weight) were dissolved in 0.5 mL of ethanol and added to a 50 mL two-necked reaction flask. Then 120 mg of iron acetylacetonate and 10 mL of triethylene glycol were added. The temperature of the solution was raised to 70 °C under vacuum and maintained for more than 15 min to remove ethanol. After filling the bottle with nitrogen or argon, the temperature was raised to 210° C. and magnetically stirred for 2 h; under the inert gas atmosphere, the temperature was ra...

Embodiment 3

[0068] (1) Measure 80mL of ethanol, 180mL of ultrapure water and 1.36mL of ammonia water, and pour them into a 500mL reaction bottle. Weigh 1.0 g of dopamine hydrochloride and dissolve it in 20 mL of water, quickly add it into the above mixed solution under vigorous stirring, and magnetically stir at room temperature for 30 h. The solution was centrifuged to collect the precipitate and washed several times with water to obtain 370nm polydopamine microspheres;

[0069] (2) Polydopamine microspheres (about 100 mg in dry weight) were dissolved in 1.0 mL of ethanol and added to a 100 mL two-necked reaction flask. Then 240 mg of iron acetylacetonate and 20 mL of triethylene glycol were added. The temperature of the solution was raised to 70 °C under vacuum and maintained for more than 15 min to remove ethanol. After filling the bottle with nitrogen or argon, the temperature was raised to 210° C. and magnetically stirred for 2 h; under the inert gas atmosphere, the temperature was...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com