Hydrophilic soft sponge, and preparation method and application thereof

A hydrophilic and soft technology, applied in applications, medical science, absorbent pads, etc., can solve the problems of slow absorption speed, insufficient softness and resilience, and achieve fast water absorption, improved hydrophilicity, and water absorption rate. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

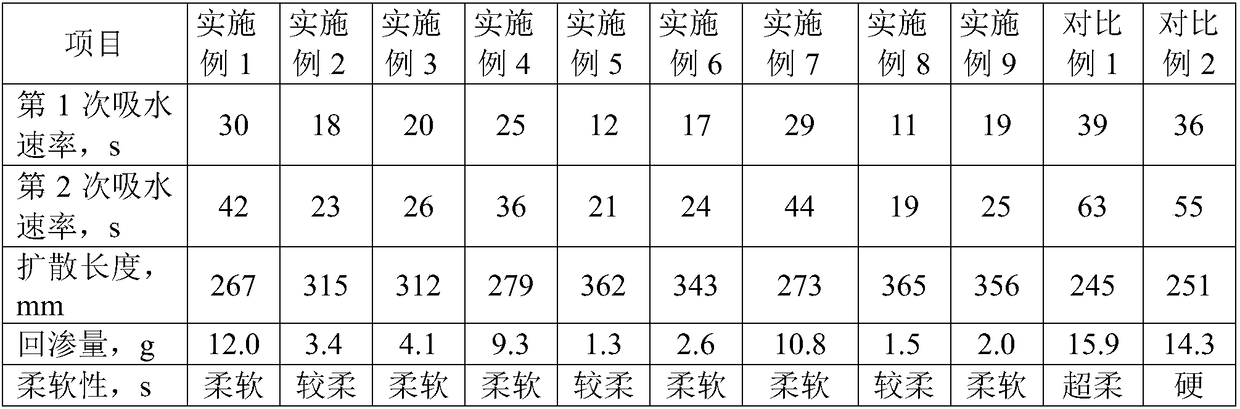

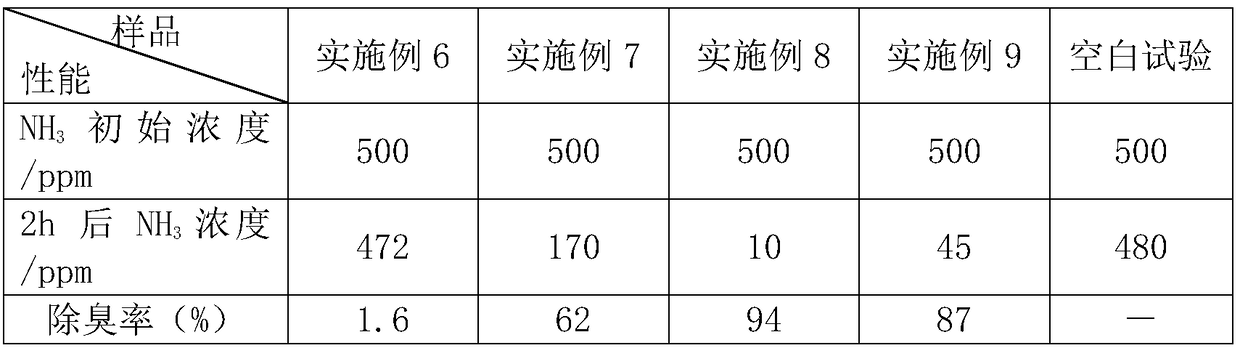

Examples

Embodiment 1

[0034] The hydrophilic soft sponge in this embodiment is made of the following raw materials in parts by weight: 10.9 parts of DEP-505S, 9.1 parts of general-purpose polyether polyol, 10 parts of toluene diisocyanate, 5 parts of dichloromethane, 0.5 parts of silicone oil, 0.1 part of methyl ethanolamine, 0.1 part of stannous octoate, 5 parts of cellulose, 1 part of superabsorbent resin, and 1.5 parts of deionized water. Wherein, the superabsorbent resin is a polyacrylic superabsorbent resin with a particle diameter of 200-410 μm.

[0035] The preparation method of the present embodiment hydrophilic soft sponge comprises the steps:

[0036] S1. Weigh each raw material in parts by weight.

[0037] S2. Put DEP-505S, general-purpose polyether polyol, cellulose, superabsorbent resin and deionized water into the storage tank, set a constant material temperature of 20-23°C, and continuously stir at a speed of 15r / min for 60min. Material A is obtained.

[0038] S3. Mix toluene diis...

Embodiment 2

[0042] The hydrophilic soft sponge in this example is made of the following raw materials in parts by weight: 36 parts of DEP-505S, 24 parts of general-purpose polyether polyol, 40 parts of toluene diisocyanate, 15 parts of methylene chloride, and 1.5 parts of silicone oil , 0.5 parts of dimethylethanolamine, 0.5 parts of stannous octoate, 15 parts of cellulose, 20 parts of superabsorbent resin, and 3 parts of deionized water. Wherein, the superabsorbent resin is a polyacrylic superabsorbent resin with a particle diameter of 200-410 μm.

[0043] The preparation method of the present embodiment hydrophilic soft sponge comprises the steps:

[0044] S1. Weigh each raw material in parts by weight.

[0045] S2. Put DEP-505S, general-purpose polyether polyol, cellulose, superabsorbent resin and deionized water into the storage tank, set a constant material temperature of 20-23°C, and continuously stir at a speed of 120r / min for 10min. Material A is obtained.

[0046] S3. Mix tolu...

Embodiment 3

[0050] The hydrophilic soft sponge in this example is made of the following raw materials in parts by weight: 27 parts of DEP-505S, 15 parts of general-purpose polyether polyol, 20 parts of toluene diisocyanate, 10 parts of methylene chloride, and 1.0 part of silicone oil , 0.8 parts of dimethylethanolamine, 0.2 parts of stannous octoate, 10 parts of cellulose, 10 parts of superabsorbent resin, and 2 parts of deionized water. Wherein, the superabsorbent resin is a polyacrylic superabsorbent resin with a particle diameter of 200-410 μm.

[0051] The preparation method of the present embodiment hydrophilic soft sponge comprises the steps:

[0052] S1. Weigh each raw material in parts by weight.

[0053] S2. Put DEP-505S, general-purpose polyether polyol, cellulose, superabsorbent resin and deionized water into the storage tank, set a constant material temperature of 20-23°C, and continuously stir at a speed of 50r / min for 30min. Material A is obtained.

[0054] S3. Mix toluen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com