A kind of microbial mixed flora and fermentation method for fermenting and producing lactic acid

A fermentation method and technology of mixed flora, applied in the field of bioengineering, can solve the problems of reduced production concentration and strength, reduced raw material utilization rate due to cell growth toxicity, and difficulty in utilization, etc., to achieve easy operation, reduced production labor costs, and durability Receptive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

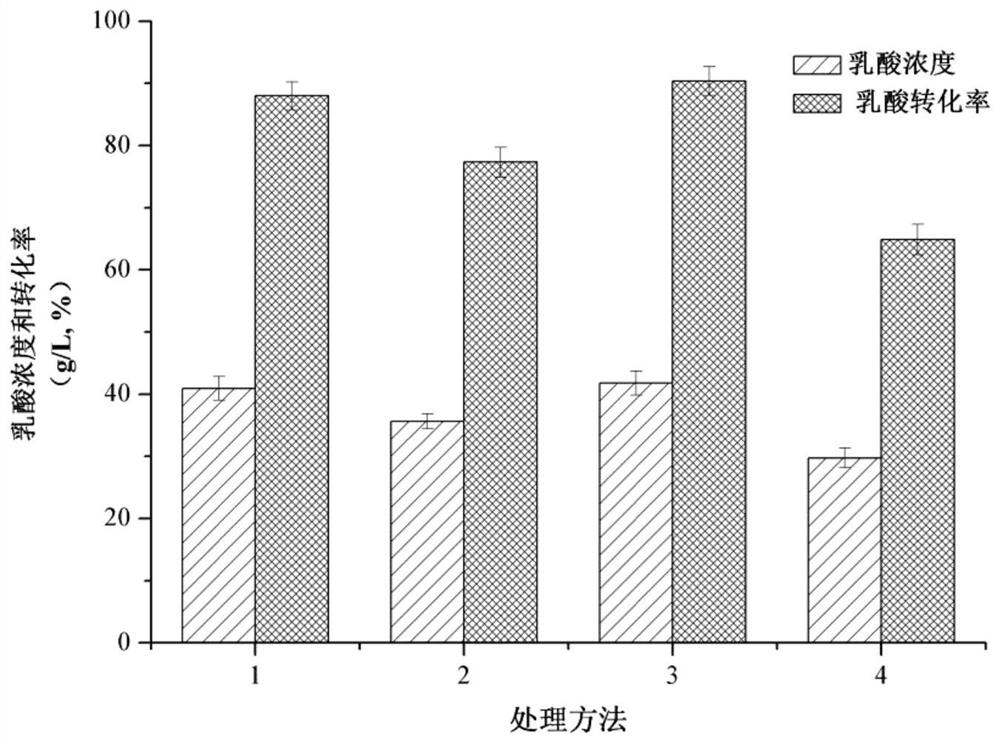

[0048] Example 1 Screening of domesticated lactic acid-producing microbial flora from bovine stomach contents

[0049] The samples were collected from a live animal slaughterhouse in Dalian. The samples of bovine stomach contents were processed in four ways: 1) suspension of bovine stomach contents, anaerobic enrichment; 2) suspension of bovine stomach contents, aerobic enrichment; 3) solid bovine stomach contents, anaerobic enrichment; 4) solid bovine stomach contents, aerobic enrichment. The preparation operation of the bovine stomach contents suspension: take 0.1kg of the fresh contents of bovine stomach in a 100mL triangular flask of physiological saline, filter the solid matter in it with sterile gauze, and take 5mL of the filtrate containing a large number of bacterial cells to inoculate the Erlenmeyer flasks and vials filled with 100mL enrichment medium for aerobic and anaerobic enrichment culture. Preparation operation of solid bovine stomach contents: take 0.1 kg of ...

Embodiment 2

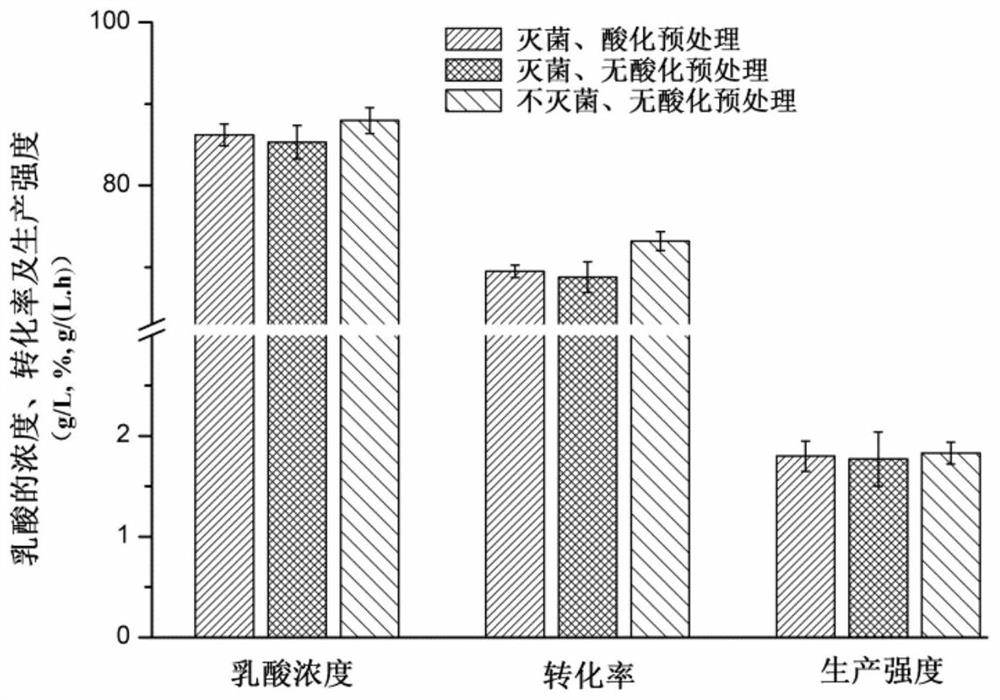

[0053] Embodiment 2 The situation that microbial flora CEE-DL15 utilizes molasses under different operating conditions

[0054] The microbial flora CEE-DL15 obtained in Example 1 was seeded, inoculated into a vial containing 100 mL of MRS medium at a volume ratio of 5%, and fermented and cultured with sugarcane molasses as a substrate. The concentration is about 100g / L. Fermentation operation conditions are divided into three types, 1) sterilization fermentation, the substrate is sugarcane molasses after acid treatment; 2) sterilization fermentation, the substrate is untreated sugarcane molasses; 3) non-sterilization fermentation, the substrate is untreated Cane molasses. After 48 hours of shaking flask fermentation, measure the concentration, transformation rate and production intensity of lactic acid in the fermented liquid such as: figure 2 shown. The results showed that the bacterial group CEE-DL15 grew well without sterilization and using untreated molasses as the sub...

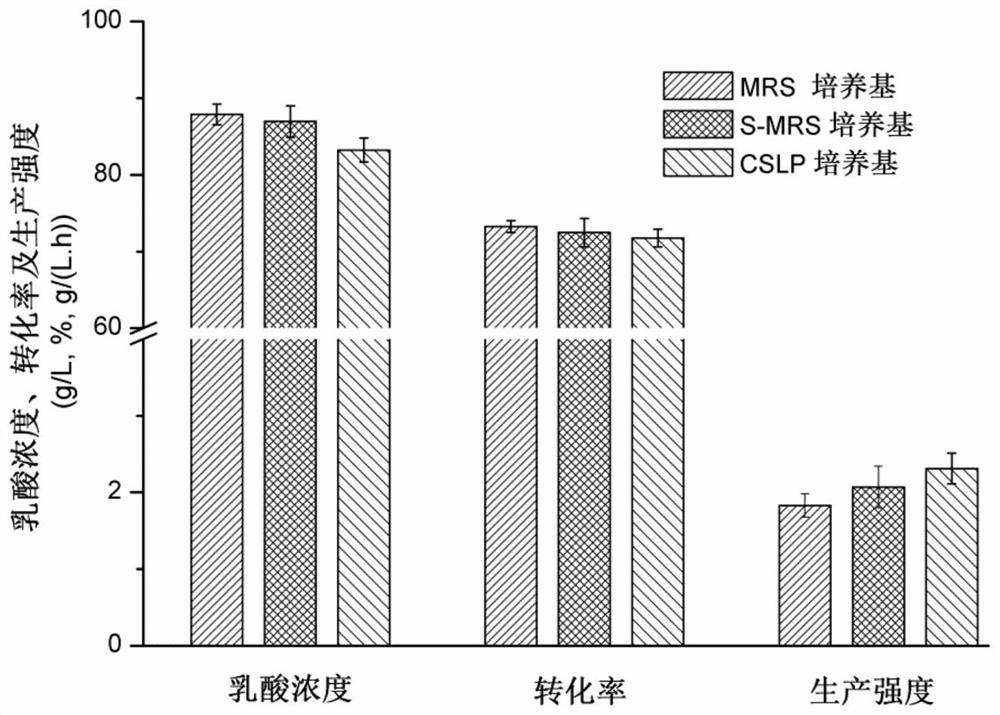

Embodiment 3

[0055] After the mixed bacterial group CEE-DL15 obtained in Example 1 was cultivated in the seed medium, it was inoculated into a vial containing 100 mL of fermentation medium at a volume ratio of 5% for cultivation, and the untreated sugarcane molasses was used as a substrate for fermentation and cultivation. , the initial untreated sugarcane molasses concentration was 250g / L. Fermentation medium is divided into three types: 1) MRS medium; 2) S-MRS medium; 3) CSLP medium; fermentation results such as image 3 shown. The bacterial colony can use the simple and cheap corn steep liquor dry powder medium (CSLP medium) to ferment lactic acid. The yield and conversion rate of lactic acid are similar to those of the other two mediums, and the production intensity is higher than that of the first two mediums. Save 50% to 200%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com