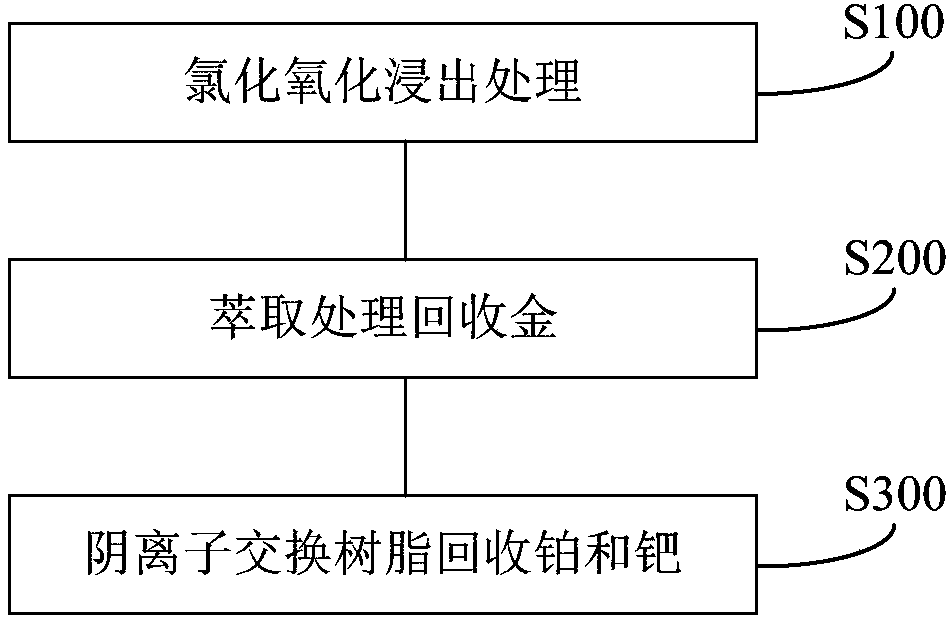

Method for extracting gold, platinum and palladium in electronic scrap copper anode mud

A technology of copper anode slime and electronic waste, applied in the direction of improving process efficiency, etc., can solve the problems of long separation and recovery process of rare and precious metals, long production cycle, and affecting capital turnover of enterprises, so as to reduce operating costs and interest payments, The effect of reducing the stay of precious metals and reducing the occupation of working capital

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

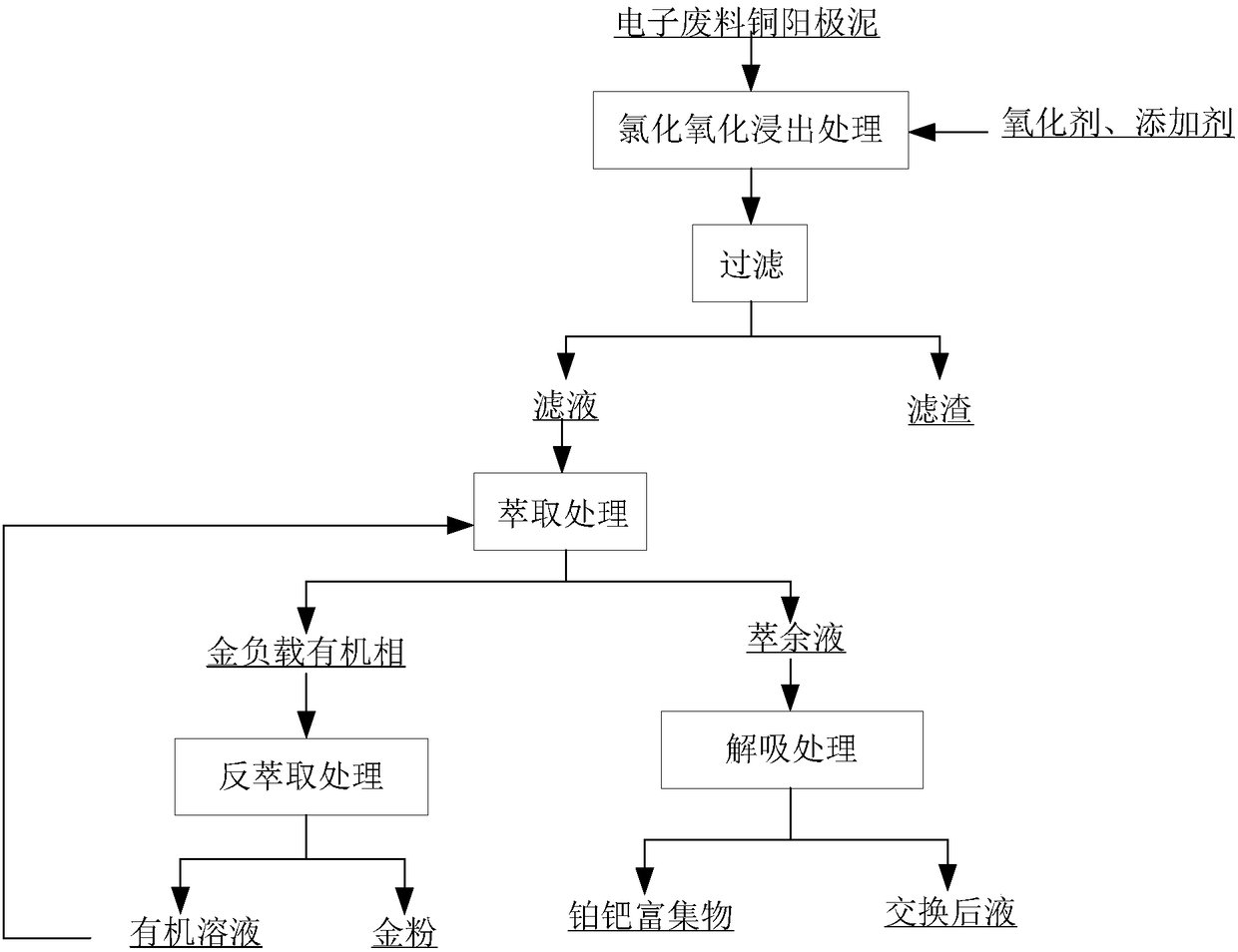

[0056] (1) Electronic scrap copper anode slime dry basis composition (mass percentage): Cu11.83%, Pb1.09%, Ni23.27%, Sn1.36%, Au1.53%, Ag33.04%, Pt0.22 %, Pd0.18%.

[0057] (2) Take 500g of electronic waste copper anode slime, add 2mol / L sulfuric acid to wash and filter, add chlorate and sulfuric acid to the filter residue, adjust the liquid-solid ratio to 8:1, chloride ion 150g / L, sulfuric acid 120g / L, at 90 Chlorination and oxidation leaching for 120 minutes at a temperature of ℃, the leaching rate is 99.03%, and the filter residue and filtrate are obtained by filtration;

[0058] (3) Filtrate acidity is adjusted to 2mol / L hydrochloric acid concentration, adopts the gold in diethylene glycol dibutyl ether (DBC) 2 stage countercurrent extraction filtrate, the extraction rate of gold is 99.01%, controls the concentration of gold in the gold-loaded organic phase It was 25g / L, washed with 1.5mol / L hydrochloric acid solution, containing 10.32g / L of gold, back-extracted with oxal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com