Method for spraying composite coating on plunger of emulsification pump and plunger including same

A composite coating, emulsification pump technology, applied in coating, metal material coating process, melt spraying and other directions, can solve the problems of high porosity, increased motion friction resistance, poor coating quality, etc. The effect of uniform surface, high bonding strength and high density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

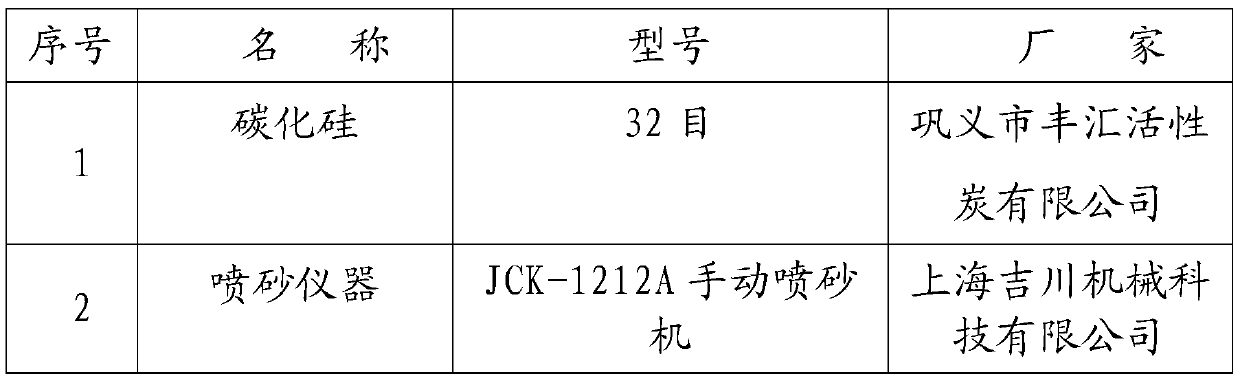

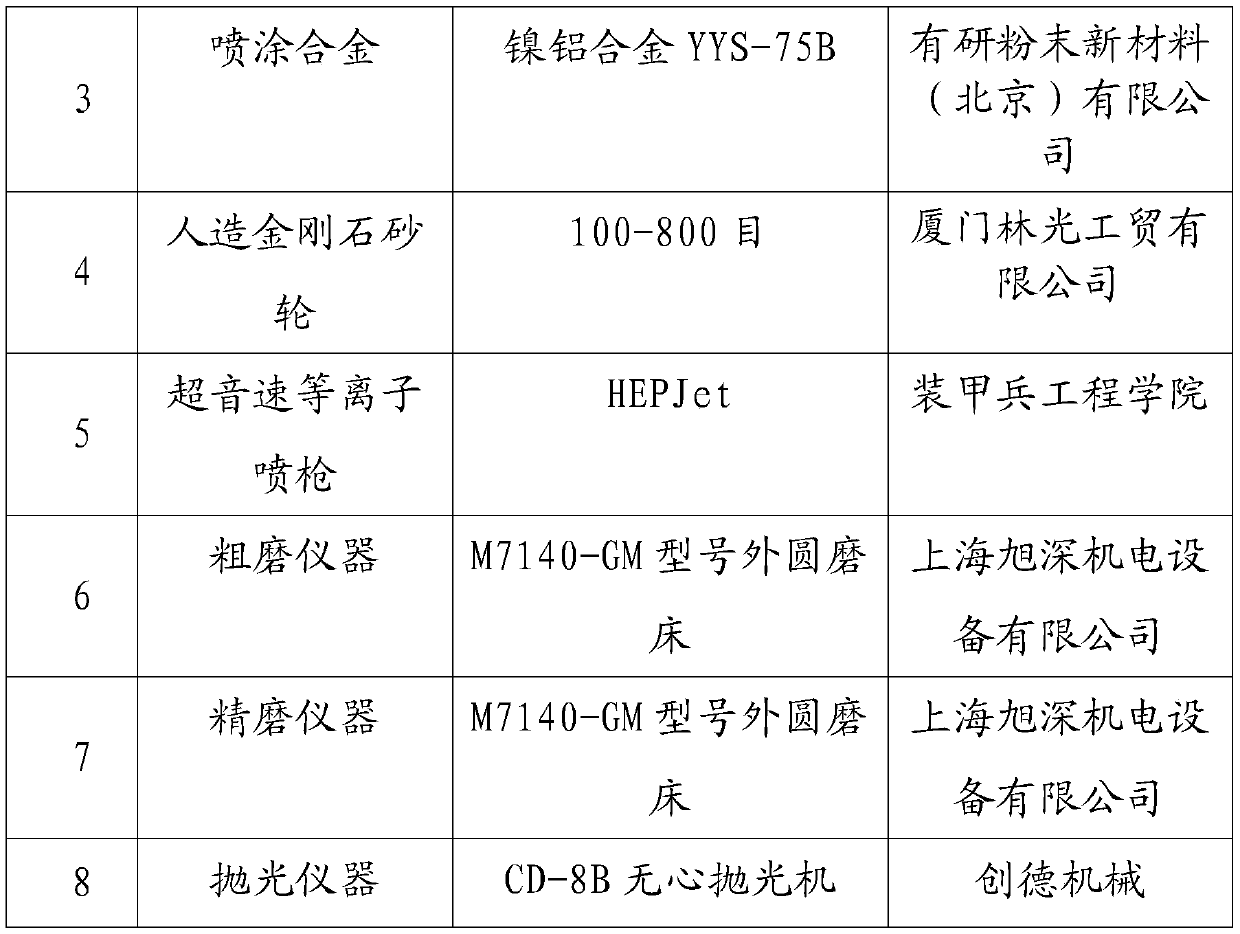

Method used

Image

Examples

Embodiment 1

[0039] (1) The friction surface of the aluminum alloy plunger is roughly machined, and the deviation from the required size is -0.2mm. The aluminum alloy plunger substrate is degreased with an organic solvent, and after drying, it is sandblasted with 300 mesh silicon carbide sand. The non-coated areas are protected with clamps. Sand blasting pressure 4kg / cm with silicon carbide sand 2 , the sandblasting distance is 10mm, and the sandblasting angle is 80°.

[0040] (2) Preheat the plunger substrate to 100°C, and spray a layer of Al by supersonic plasma spraying method 2 o 3 and NiCrAl powder as a composite transition layer, Al in the composite transition layer 2 o 3 The weight fraction of the composite transition layer is 10%, and the thickness of the obtained composite transition layer is 0.03mm.

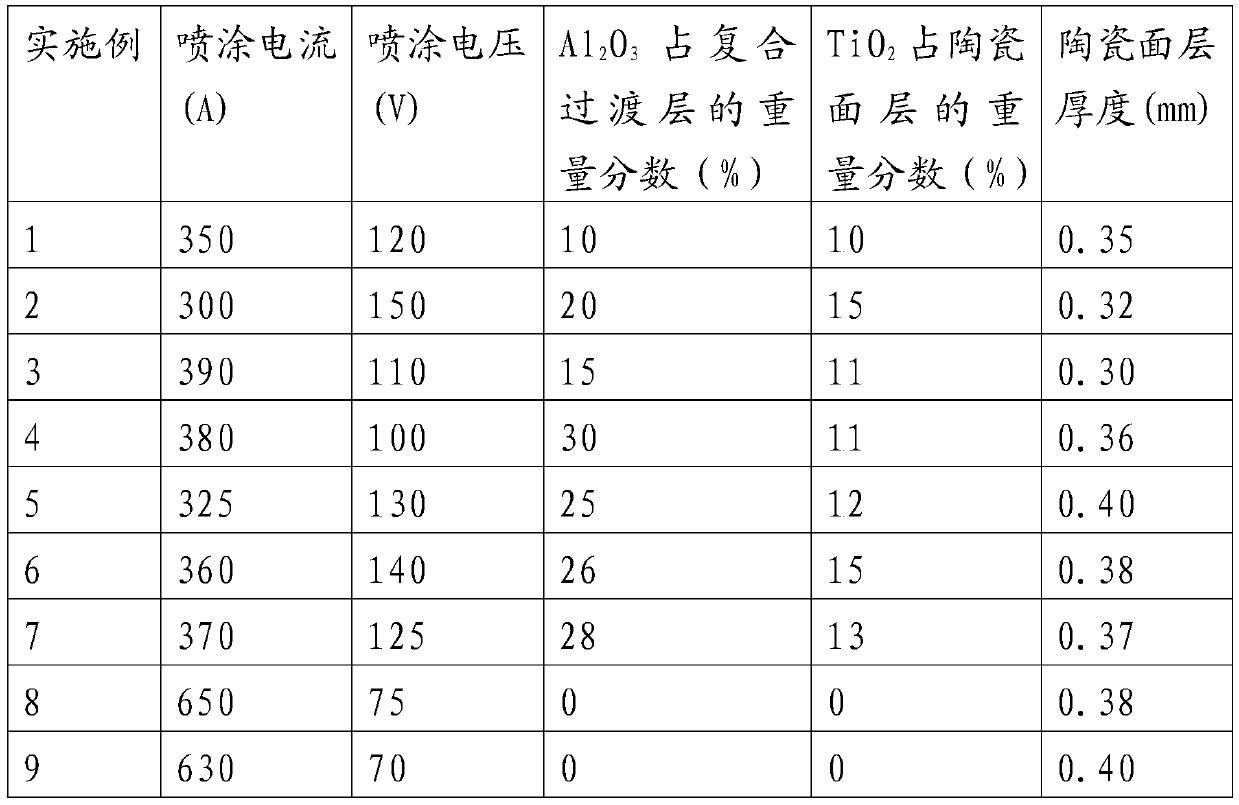

[0041] (3) Preparation of TiO by supersonic plasma spraying 2 The weight percent is 10% Al 2 o 3 -TiO 2 For the ceramic surface layer, the spraying current is 350A, the spr...

Embodiment 2

[0044] (1) The friction surface of the aluminum alloy plunger is roughly machined, and the deviation from the required size is -0.3mm. The aluminum alloy plunger substrate is degreased with an organic solvent, and after drying, it is sandblasted with 300 mesh silicon carbide sand. The non-coating area is protected with a fixture, and the sandblasting pressure of silicon carbide sand is 8kg / cm 2 , the sandblasting distance is 20mm, and the sandblasting angle is 90°.

[0045] (2) Preheat the plunger base to 100°C, and spray a layer of NiCrAl and Al with supersonic plasma spraying method 2 o 3 Powder as composite transition layer, Al 2 o 3 The weight fraction of the composite transition layer is 20%, and the obtained thickness is 0.03mm.

[0046] (3) Preparation of TiO by supersonic plasma spraying 2 The weight percent is 15% TiO 2 -Al 2 o 3 For the ceramic surface layer, the spraying current is 300A, the spraying voltage is 150V, and the thickness of the ceramic surface ...

Embodiment 3-7

[0050] Embodiment 3-7 adopts the same method as Embodiment 2, and different specific spraying conditions and performance parameters are shown in Tables 2 and 3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com