High-performance lithium-sulfur battery positive electrode material and preparation method thereof

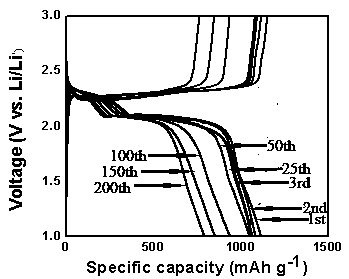

A lithium-sulfur battery and cathode material technology, applied in the field of materials, can solve the problems of low effective load, uneven loading, uneven sulfur loading, etc., and achieves strong industrial practicability, extremely strong cycle stability, The effect of increasing the payload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

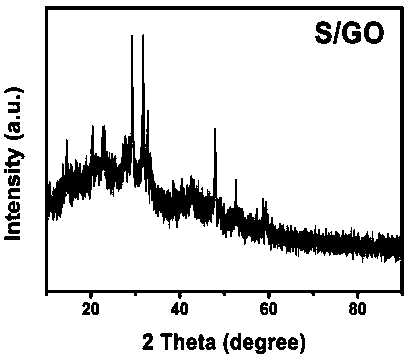

[0031] The first step, the preparation of graphene oxide:

[0032] Graphene oxide was prepared by improving the Hummers method;

[0033] The second step, the preparation of graphene / sulfur cathode material:

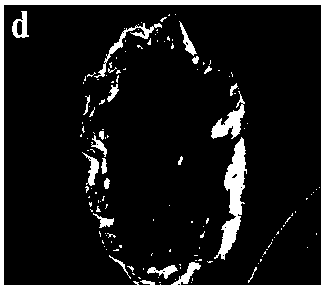

[0034] Weigh the required amount of graphene solution A and nano-sulfur solution B according to the volume ratio of 1:10, place A solution on a constant temperature magnetic stirrer for stirring, and use a rubber dropper to draw B solution at 2 drops per second After the titration, the mixed solution C of A solution and B solution was obtained, and then the mixture was ultrasonically dispersed for 4 hours at a power of 600W using an ultrasonic cell pulverizer, and the obtained uniform C solution was spray-dried, sprayed What the drying equipment used was ordinary air pressure, the air intake volume was 6 cubic meters per minute, the intake air temperature was 200°C, the feed rate was 8 ml / min, and the needle passing rate was 1 time / 10 seconds. The graphene / sulfur cathod...

Embodiment 2

[0036] The first step, the preparation of graphene oxide:

[0037] Graphene oxide was prepared by improving the Hummers method;

[0038] The second step, the preparation of graphene / sulfur cathode material:

[0039] Weigh the required amount of graphene solution A and nano-sulfur solution B according to the volume ratio of 1:5, place A solution on a constant temperature magnetic stirrer for stirring, and use a rubber dropper to draw B solution at 1 drop per second After the titration, the mixed solution C of A solution and B solution was obtained, and then the mixture was ultrasonically dispersed for 2 hours at a power of 500W using an ultrasonic cell pulverizer, and the obtained uniform C solution was spray-dried, sprayed What the drying equipment used was ordinary air pressure, the air intake volume was 3 cubic meters per minute, the intake air temperature was 150°C, the feed rate was 4 ml / min, and the needle passing rate was 1 time / 5 seconds. The graphene / sulfur cathode m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com