Nanometer fibrils cellulose surface hydrophobic modification method

A technology of nanocellulose and hydrophobic modification, which is applied in the field of nanocellulose and achieves the effects of strong controllability, simple and easy preparation method and short reaction period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] Place 2000mL of toluene and 100g of freeze-dried unmodified nanofibril cellulose powder in a 5L reactor with a stirring and condensing reflux device, start the stirring device, mix the solvent and nanocellulose evenly, and adjust the temperature to 90°C. Take 5g, 10g, 20g, 30g, 50g of AKD wax powder and dissolve it with 100g of toluene. After the AKD wax powder is completely dissolved, add it to the reactor to start the grafting reaction, keep the temperature, and the reaction time is 6 hours . After the reaction is finished, the reactants are washed with toluene, the unreacted toluene solvent and the unreacted AKD are recovered, and the dry hydrophobic nanofibril cellulose fibers are obtained after filtering, volatilizing, and collecting the organic solvent. The properties of nanocellulose after the reaction are shown in Table 10.

[0044] AKD(g)

Embodiment 2

[0046]Put 2000mL of toluene and 100g of freeze-dried TEMPO oxidized nanocellulose powder in a 5L reactor with a stirring and condensing reflux device, start the stirring device, mix the solvent and nanocellulose evenly, and adjust the temperature to 120 ℃. Take 30g of AKD wax powder, dissolve it in 100g of toluene and add it into the reactor, keep the temperature, and the reaction time is 4 hours. After the reaction, use toluene to wash the reactant, recover the unreacted toluene solvent and unreacted AKD, filter and volatilize the organic solvent and then hydrophobic nano-fibril cellulose fibers, the modified nano-cellulose can be dispersed in Organic solvents such as isopropanol and methylene chloride.

Embodiment 3

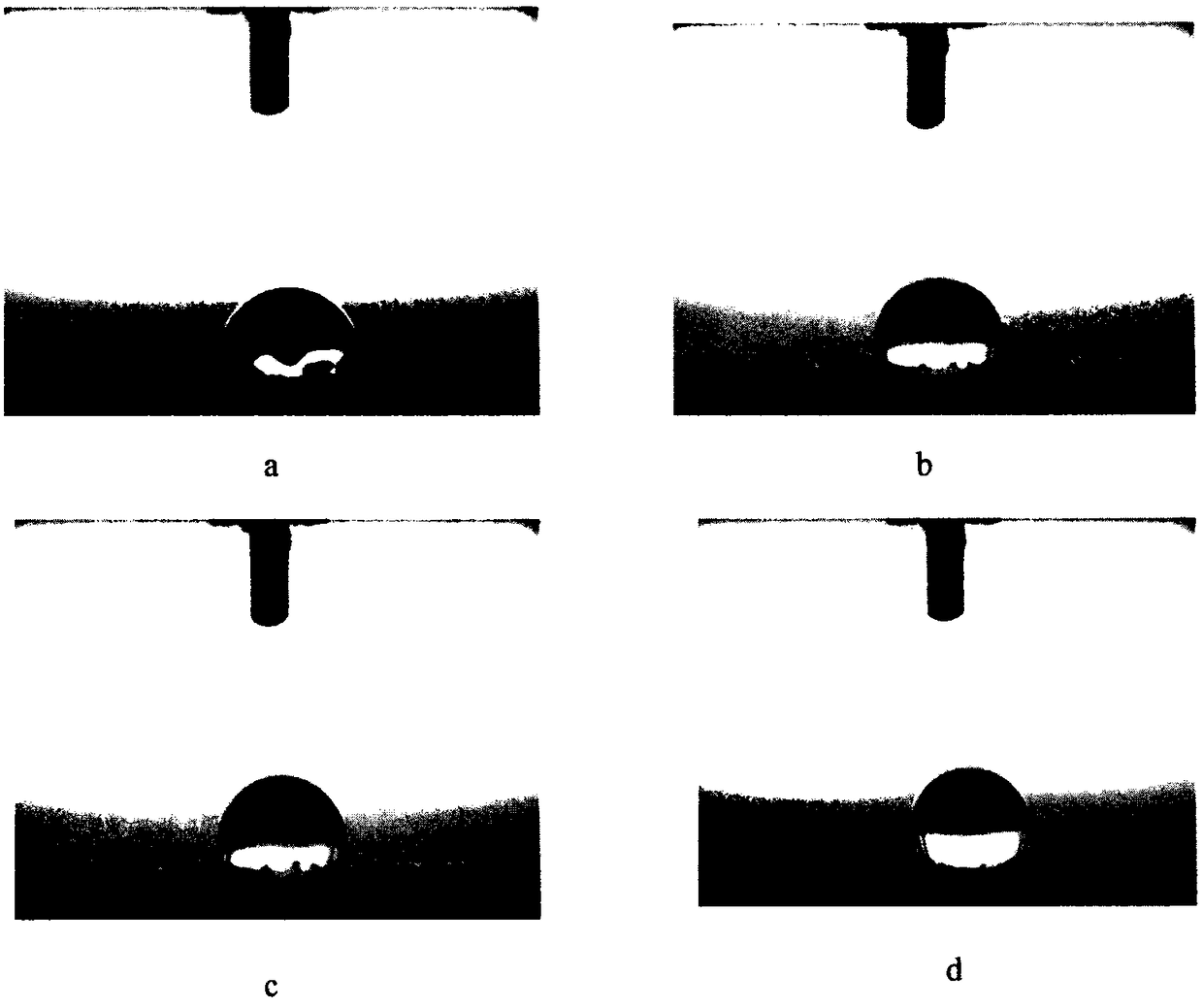

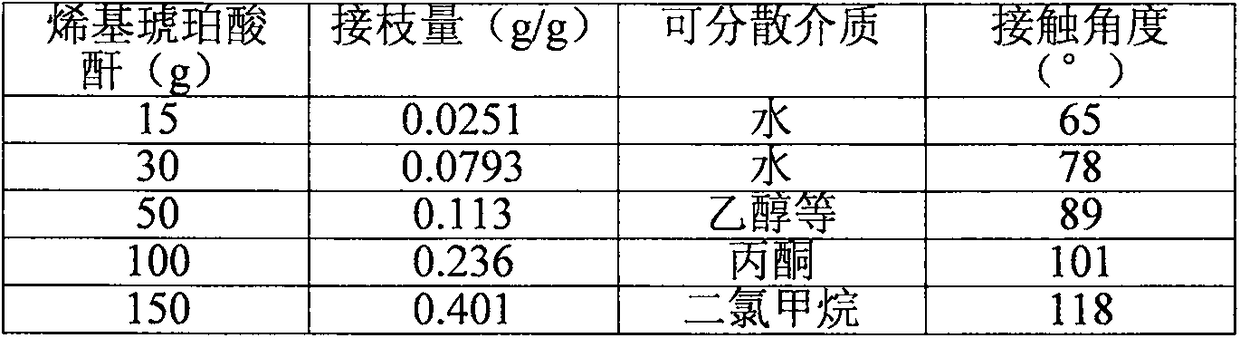

[0048] Place 3000mL N, N-dimethylformamide and 300g freeze-dried TEMPO nanofibril cellulose powder in a 5L reactor with a stirring and condensing reflux device, start the stirring device, and mix the solvent with the nanofiber Mix the ingredients evenly, and adjust the temperature to 60°C. Weigh 4, add lutidine 15g to the reaction system and stir for 15 minutes, weigh dodecenyl succinic anhydride 15g, 30g, 50g, 100g, 150g and add to the system, keep the reaction temperature and stirring, the reaction time is 8 Hour. After the reaction, filter the reactant with suction to recover unreacted dodecenyl succinic anhydride and N,N-dimethylformamide, wash and dry to obtain nanofibrillar cellulose fibers modified by dodecenyl succinic anhydride . The performance of the nanocellulose after the reaction is as follows:

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| dryness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com