Method for processing emulsified crude oil containing iron sulfide solid particles

A technology for emulsifying crude oil and solid particles, which is applied in the treatment of hydrocarbon oil, dehydration/demulsification by chemical methods, petroleum industry, etc. It can solve the problems of large chelating dose, inability to eliminate impact, corrosion, etc., and achieve the goal of reducing the oil content of drainage Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

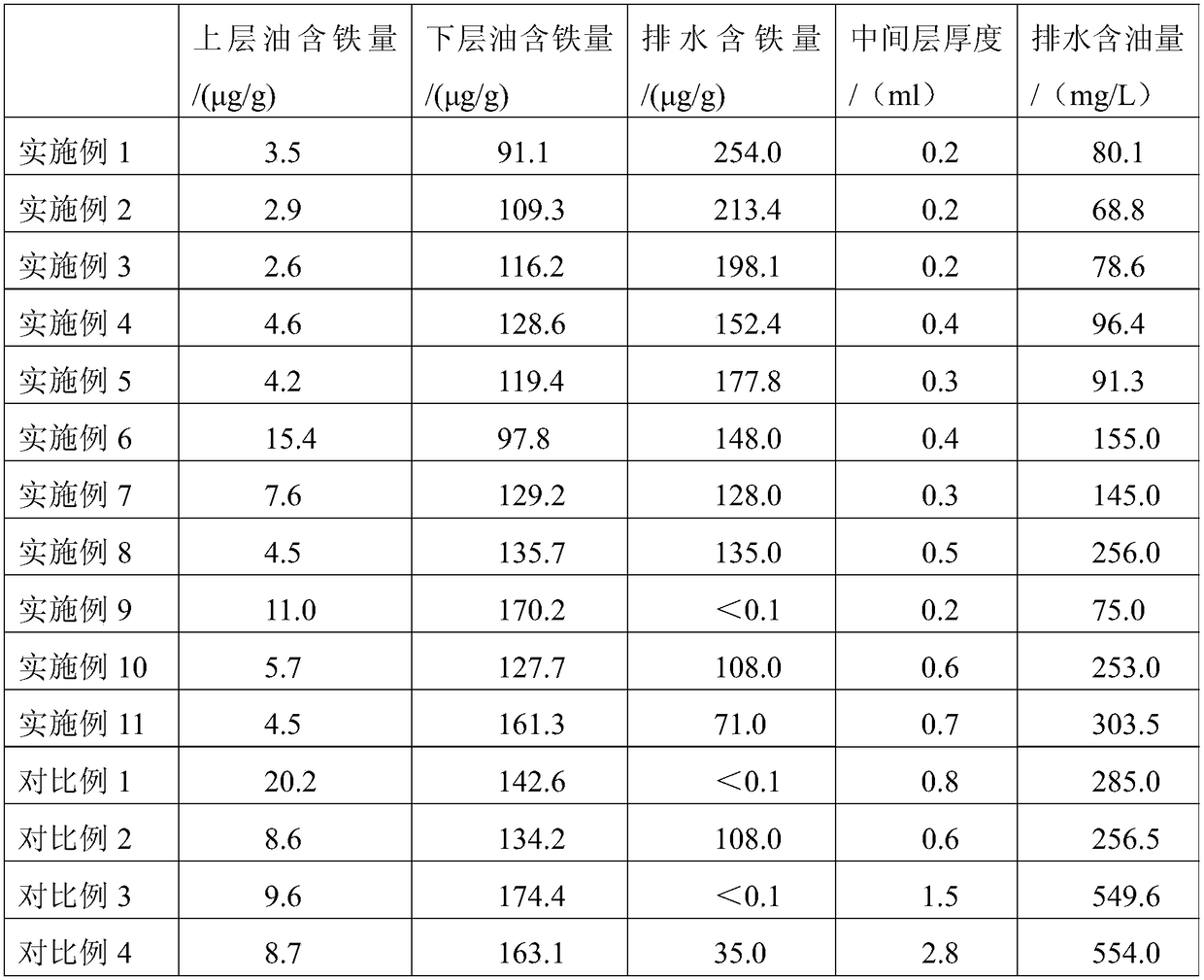

Examples

preparation example Construction

[0025] Wherein, the preparation method of the alkyl ester of styrene-maleic anhydride copolymer (can refer to CN101352666A) can comprise: first prepare styrene-maleic anhydride copolymer, then carry out styrene-maleic anhydride copolymer and fatty alcohol Esterification reaction.

[0026] Styrene-maleic anhydride copolymer can be prepared by conventional method, preferably adopt solution polymerization method to prepare, specifically, with aromatic hydrocarbon such as benzene, toluene, xylene as solvent, under initiator effect, styrene and maleic anhydride Carry out the polymerization reaction, the product is precipitated from the solution as fine white particles, and the solvent can be removed by filtration to obtain the styrene-maleic anhydride copolymer. Preferably, the molar ratio of styrene and maleic anhydride used in the reaction is (0.8-1.5):1, more preferably (0.9-1.1):1.

[0027] The styrene used needs to be pretreated before use to remove the polymerization inhibit...

preparation example 1

[0060] This preparation example is used to illustrate the preparation method of styrene-maleic anhydride copolymer octadecyl ester (stearyl alcohol SMA).

[0061] Add 9.8g of maleic anhydride and 60ml of toluene to the three-necked flask, dissolve at 60°C, add 10.3g of styrene and 0.2g of dodecyl mercaptan, and add dropwise 0.24g of BPO dissolved in it at 85±5°C 40ml of toluene solution was reacted for 6h and filtered, and the product was vacuum-dried at 80°C for 4h to obtain a styrene-maleic anhydride copolymer (SMA) with a molecular weight of 5000. Add 100ml of toluene in the there-necked flask, add SMA64g (0.032mol), stearyl alcohol 8.6g, p-toluenesulfonic acid 0.5g, after reflux reaction 1h, install water separator, reflux divide water 6h, obtain the degree of esterification as 90% styrene-maleic anhydride copolymer stearyl A1.

preparation example 2

[0063] This preparation example is used to illustrate the preparation method of styrene-maleic anhydride copolymer cetyl ester (cetyl alcohol SMA).

[0064] According to the method of Preparation Example 1, the difference is that 8.6 g of stearyl alcohol was replaced by 7.7 g of cetyl alcohol to obtain styrene-maleic anhydride copolymer cetyl ester A2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com