Preparation method of degradable oil absorbing material

An oil-absorbing material and a technology for preparation steps, which are applied in the field of preparation of degradable oil-absorbing materials, can solve the problems of high comprehensive waste cost, low oil-water selectivity, poor reusability, etc., and achieve good adaptability, good oil-water selectivity, High biocompatibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

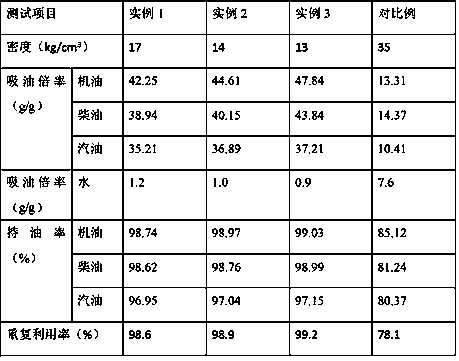

Examples

example 1

[0026] Take 200g of sepiolite, put it in a stone grinder and grind for 2 hours, pass through a 200-mesh sieve to obtain sepiolite powder, add 400mL of phosphoric acid solution with a mass fraction of 30% to the plastic basin, pour the sepiolite powder into the plastic basin, and stir Disperse for 40 minutes to obtain a sepiolite suspension, and feed 8L of ammonia into the sepiolite suspension to obtain a living fossil slurry; take 5g of Enteromorpha and place it in a Soxhlet extractor, and use 80mL of 20% ethyl acetate Ethanol solution, extract at 85°C for 6 hours, remove the lipid extract, then add 40mL of sodium carbonate solution with a mass fraction of 20% to the Soxhlet extractor, extract polysaccharides at 58°C, and filter Separation of Enteromorpha slag, followed by soaking and oxidizing the Enteromorpha slag with 10% sodium chlorite solution for 2 hours, filtering and removing the filtrate to obtain the residue, and immersing the residue in 40% potassium hydroxide solut...

example 2

[0028] Take 225g of sepiolite, place it in a stone grinder and grind for 2.5h, pass through a 200-mesh sieve to obtain sepiolite powder, add 450mL of phosphoric acid solution with a mass fraction of 30% into the plastic basin, pour the sepiolite powder into the plastic basin, Stir and disperse for 45 minutes to obtain a sepiolite suspension, and inject 9L of ammonia into the sepiolite suspension to obtain a living fossil slurry; take 7g of Enteromorpha and place it in a Soxhlet extractor, and use 90mL of 20% ethyl acetate Extract the ethanol solution at 87°C for 7 hours, remove the lipid extract, then add 45mL of sodium carbonate solution with a mass fraction of 20% to the Soxhlet extractor, extract polysaccharides at 60°C, and filter Finally, the Enteromorpha slag is obtained by separating the Enteromorpha slag, and then the Enteromorpha slag is impregnated and oxidized for 2.5 hours with a sodium chlorite solution with a mass fraction of 10%, and the filtrate is removed by fi...

example 3

[0030] Take 250g of sepiolite, put it in a stone grinder and grind for 3 hours, pass through a 200-mesh sieve to obtain sepiolite powder, add 500mL of phosphoric acid solution with a mass fraction of 30% to the plastic basin, pour the sepiolite powder into the plastic basin, and stir Disperse for 50 minutes to obtain a sepiolite suspension, and feed 10L of ammonia gas into the sepiolite suspension to obtain a living fossil slurry; take 10g of Enteromorpha and place it in a Soxhlet extractor, and use 100mL of 20% ethyl acetate Ethanol solution, extract at 90°C for 8 hours, remove the lipid extract, then add 50mL of sodium carbonate solution with a mass fraction of 20% to the Soxhlet extractor, extract polysaccharides at 62°C, and filter Separation of Enteromorpha slag, followed by soaking and oxidizing the Enteromorpha slag with 10% sodium chlorite solution for 3 hours, filtering and removing the filtrate to obtain the residue, and immersing the residue in 40% potassium hydroxid...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com