Z-shaped semiconductor photocatalyst with trapezoid structure as well as preparation method and application thereof

A trapezoidal structure and photocatalyst technology, applied in the field of photocatalysis, can solve the problems of easy recombination and less semiconductor catalysts, and achieve the effects of stable properties, improved efficiency and improved efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

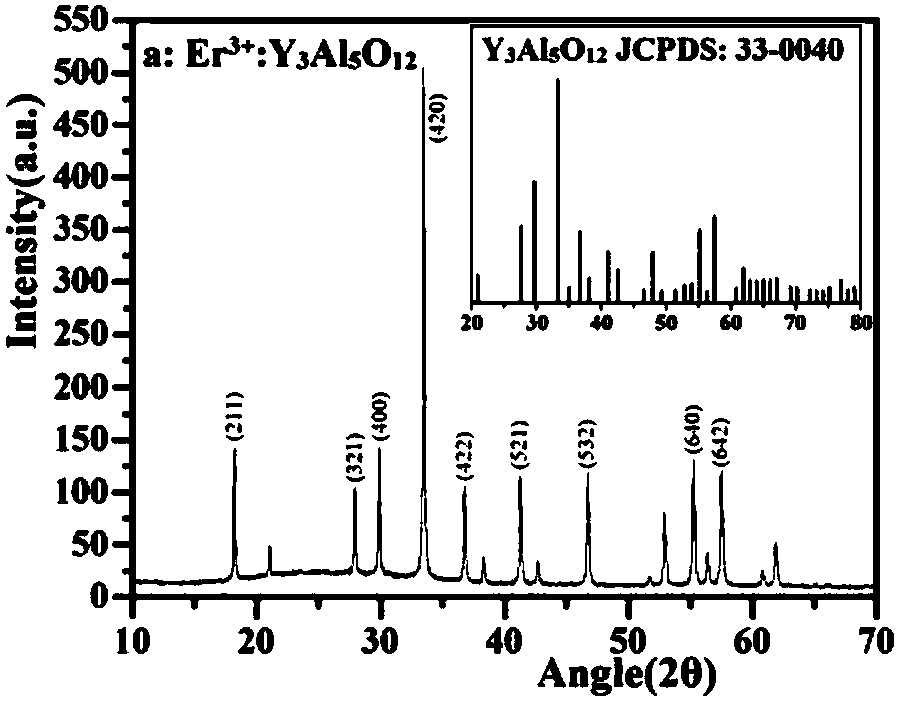

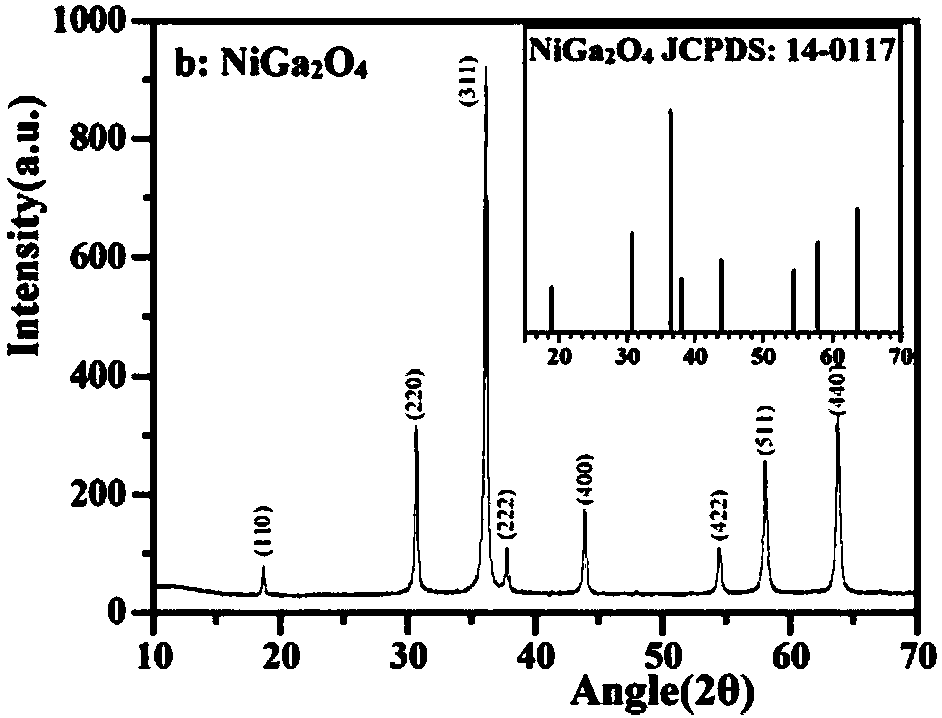

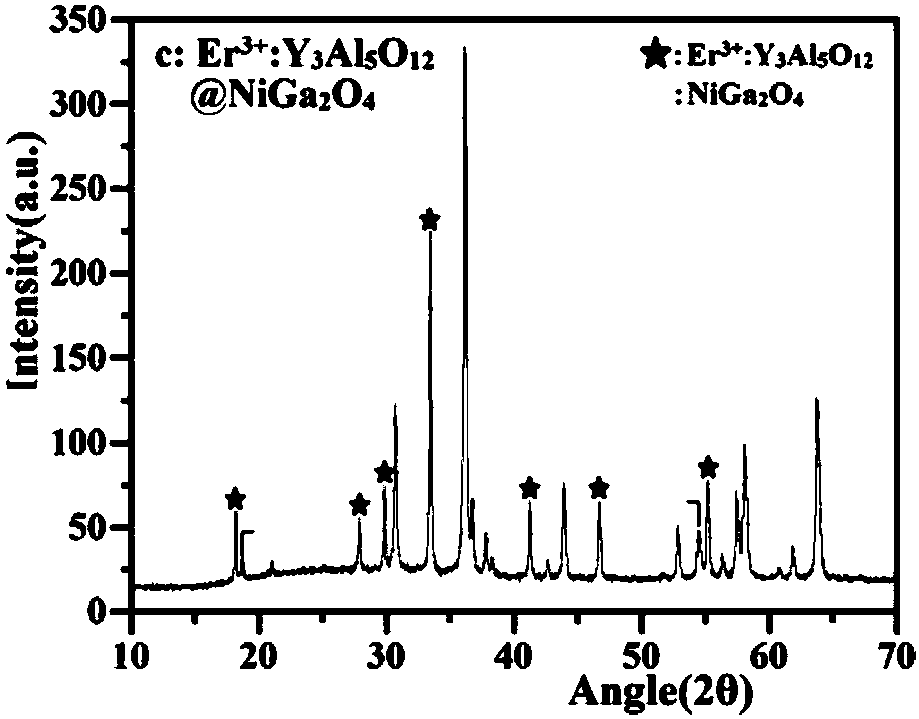

[0030] Embodiment 1 has the Z-type semiconductor photocatalyst Er of trapezoidal structure 3+ :Y 3 al 5 o 12 @NiGa 2 o 4 / NiS / Bi 2 sn 2 o 7

[0031] (1) Preparation of NiGa 2 o4 nano powder

[0032] 0.376g Ga 2 o 3 The powder was added to 50 mL of 1mol / L nickel nitrate solution, and the resulting mixture was adjusted to pH 12 with sodium hydroxide (stirring for 30 min while adjusting), and the resulting suspension solution was transferred to a reactor at 180°C for 48 h, cooled to room temperature, A light blue precipitate was obtained, washed several times with deionized water, and then dried at 60°C for 8 hours to obtain NiGa 2 o 4 Powder. Grind the powder finely, bake it in a muffle furnace at 500°C for 2 hours, take it out, and then grind it to get NiGa 2 o 4 Nano powder.

[0033] (2) Preparation of Bi 2 sn 2 o 7 nano powder

[0034] 8.76g Bi(NO 3 ) 3 ·5H 2 O and 5.40 g K 2 SnO 3 ·3H 2 O was mixed in 150ml deionized water, and adjusted to PH=12 wi...

Embodiment 2

[0054] Example 2 Er 3+ :Y 3 Al 5 o 12 @NiGa 2 o 4 / NiS / Bi 2 sn 2 o 7 Application in photocatalytic conversion of nitrite and sulfite

[0055] (1) Effect of simulated sunlight irradiation time and corresponding reaction kinetics on the photocatalytic conversion rate of nitrite and sulfite

[0056] Perform Er under simulated sunlight 3+ :Y 3 Al 5 o 12 @NiGa 2 o 4 / NiS / Bi 2 sn 2 o 7 Photocatalytic conversion of nitrite and sulfite by photocatalysts. Before light exposure, will contain NO 2 - and SO 3 2- The solution was stirred for 30 min in the dark and reached adsorption-desorption equilibrium. Then, solution samples were taken every 1.0 hour, and the conversion of nitrite and sulfite was checked by ion chromatography. From Figure 5a It can be seen that with the increase of the simulated sunlight irradiation time, the photocatalytic conversion rate shows an upward trend. Under irradiation within 4.00 hours, for NO 2 - and SO 3 2- , and their photoc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com