Aureomycin fermentation culture medium capable of reducing aureomycin loss in filtrate

A technology of fermentation medium and chlortetracycline, applied in the direction of fermentation, microorganism-based methods, microorganisms, etc., to achieve the effect of reducing residues, reducing the loss of chlortetracycline, and releasing inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025]A kind of aureomycin fermentation medium that reduces the loss of aureomycin in the filtrate, it adopts L-calcium lactate 25% to replace the calcium carbonate in the aureomycin fermentation medium in the comparison example; Concrete, in every liter of fermentation medium aqueous solution Contains 20g of peanut cake powder, 12g of soybean cake powder, 120g of corn starch, 1g of yeast powder, 0.5g of amylase, 2g of sodium chloride, 8g of ammonium sulfate, 6g of calcium carbonate, 2g of L-calcium lactate, 0.15g of magnesium sulfate, and 0.1g of soybean oil g. Other operating procedures are the same as the control example, and the comparison results of the test are as follows:

[0026] .

Embodiment 2

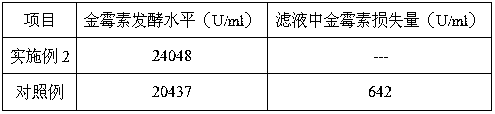

[0028] A kind of chlortetracycline fermentation medium that reduces the loss of chlortetracycline in the filtrate, it adopts L-calcium lactate 37.5% to replace the calcium carbonate in the chlortetracycline fermentation medium in the comparison example; Concrete, in every liter of fermentation medium aqueous solution Contains 20g of peanut cake powder, 12g of soybean cake powder, 120g of corn starch, 1g of yeast powder, 0.5g of amylase, 2g of sodium chloride, 8g of ammonium sulfate, 5g of calcium carbonate, 3g of L-calcium lactate, 0.15g of magnesium sulfate, and 0.1g of soybean oil g. Other operating procedures are the same as those of the comparative example. The comparison results of the test are as follows:

[0029]

[0030] --- : Indicates that no titer was detected.

Embodiment 3

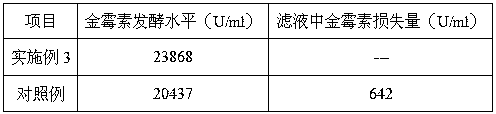

[0032] A kind of aureomycin fermentation medium that reduces the loss of aureomycin in the filtrate, it adopts L-calcium lactate 50% to replace the calcium carbonate in the aureomycin fermentation medium in the comparison example; Concrete, in every liter of fermentation medium aqueous solution Contains 20g of peanut cake powder, 12g of soybean cake powder, 120g of corn starch, 1g of yeast powder, 0.5g of amylase, 2g of sodium chloride, 8g of ammonium sulfate, 4g of calcium carbonate, 4g of L-calcium lactate, 0.15g of magnesium sulfate, and 0.1g of soybean oil g. Other operating procedures are the same as the control example, and the comparison results of the test are as follows:

[0033]

[0034] --- : Indicates that no titer was detected.

[0035] In summary, through the comparison and analysis of the examples and the control examples, it is found that the use of 25-50% L-calcium lactate to replace the calcium carbonate in the control examples can effectively improve the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com