Recombinant alginate lyase and construction method and application thereof

A technology of alginate lyase and alginate, which is applied in the fields of application, hydrolase, botanical equipment and methods, etc., can solve the problems of low expression level and application of restriction enzymes, achieve high enzyme activity level, easy separation and purification, The effect of low impurity protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1: Cloning and analysis of the full-length gene of alginate lyase Aly-Cob

[0029] (1) The gene encoding alginate lyase was obtained by constructing a Fosmid metagenomic library for the mixture of environmental samples and production waste in the kelp stacking place in the kelp production and processing plant. The gene was amplified by PCR. When designing primers, restriction sites BamH I and Hind III were added to the 5' ends of the primers respectively. The primer sequences were:

[0030] AlyC-F: 5'-CG GGATCC ATGCGTAACACCCGTGTGC-3', underlined is the BamH I restriction site;

[0031] AlyC-R: 5'-CCC AAGCTT TCATTGCATCTCACCGCTCT-3', the Hind III restriction site is underlined.

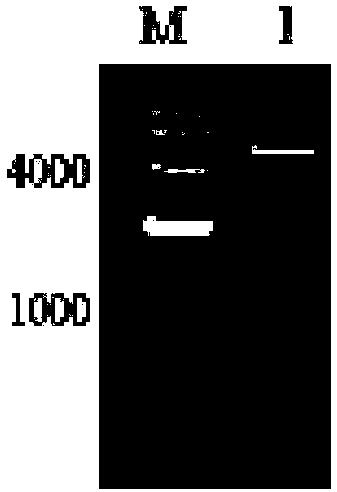

[0032] PCR conditions are: 94°C pre-denaturation, 3min; 94°C, 30s; 58°C, 30s; 72°C, 1min; a total of 30 cycles, the last 72°C, 10min. Agarose gel electrophoresis showed a specific band at about 1.0kb ( figure 1 ). It was excised from the agarose gel and purified using a DNA Gel Ex...

Embodiment 2

[0036] Embodiment 2: Recombinant bacterial construction and enzyme production

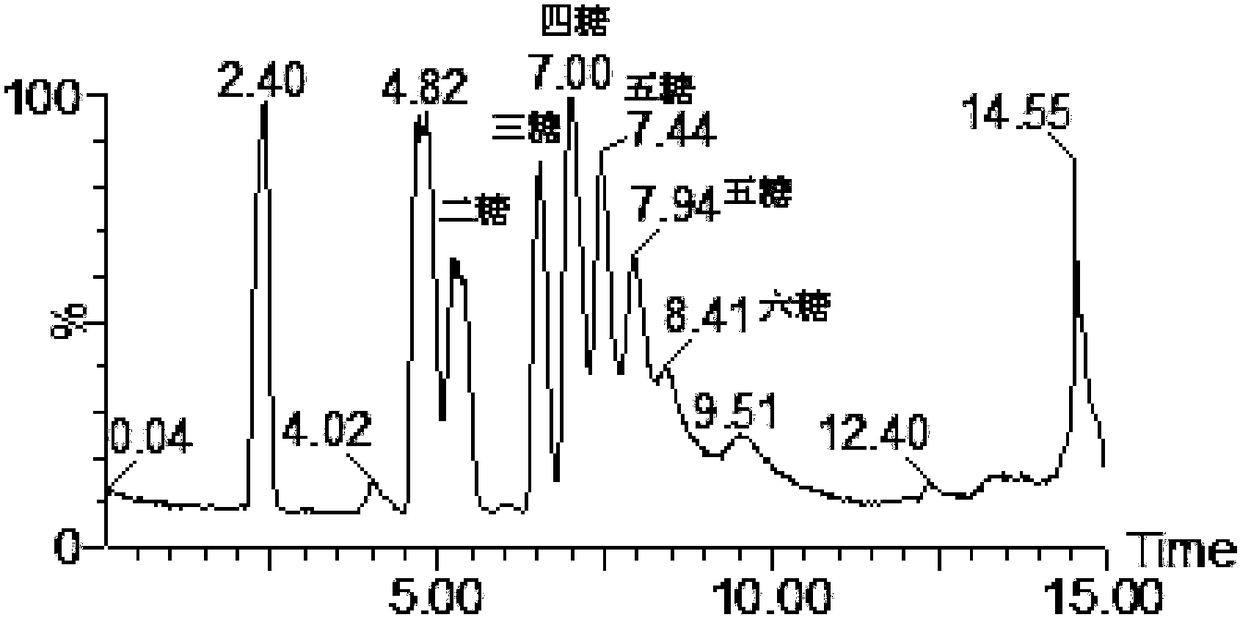

[0037] The construction of the recombinant strain E.coli BL21pLysS / pET-28a(+)-aly-cob: the target gene sequence aly-cob and the plasmid pET-28a(+) were cut with restriction endonucleases BamH I and Hind III respectively, and Transformed into E.coli BL21pLysS after T4 ligase ligation. Pick a single colony for liquid culture, extract the recombinant plasmid, verify it by PCR, and use BamH I and Hind III for double enzyme digestion verification. Get two fragments with lengths of about 5.3kb and 1kb respectively, such as figure 2 , proving that the alginate lyase gene has been successfully cloned into the expression vector pET-28a(+) and transformed into the expression host E.coli BL21pLysS, the recombinant plasmid was named pET-28a(+)-aly-cob, the recombinant strain Named as E.coliBL21pLysS / pET-28a(+)-aly-cob.

[0038] Induced expression of recombinant bacteria: insert the constructed recombinant ...

Embodiment 3

[0042] Example 3: Research on the enzymatic properties of recombinant alginate lyase Aly-Cob

[0043] The recombinant strain E.coli BL21pLysS / pET-28a(+)-aly-cob was induced to produce enzyme, and the enzymatic properties of the crude enzyme liquid obtained from fermentation were purified.

[0044] 1) Optimum temperature and temperature stability of recombinant alginate lyase Aly-Cob: Measure the enzyme activity of recombinant alginate lyase Aly-Cob solution at 25-65°C with appropriate concentration, respectively Each of the above-mentioned different temperatures was incubated for 30 minutes to measure the residual enzyme activity, and the highest enzyme activity was defined as 100%. In addition, the Aly-Cob enzyme solution was incubated in water baths at 35, 40, 45, 55, and 65°C, respectively. Samples were taken every 10 minutes to determine the residual enzyme activity of the sample, and the stability of the enzyme at different temperatures was determined. Finally, it was d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Theoretical molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com