Medical nanofiber reinforced hydrophilic composite material as well as preparation method and application thereof

A composite material and nanofiber technology, used in medical science, prosthesis, surgery, etc., can solve the problems of slow degradation, broken and poor products, and 1 to 2 months to fall off, and achieve good tensile strength and fracture. Elongation, moderate degradation cycle, good biodegradability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

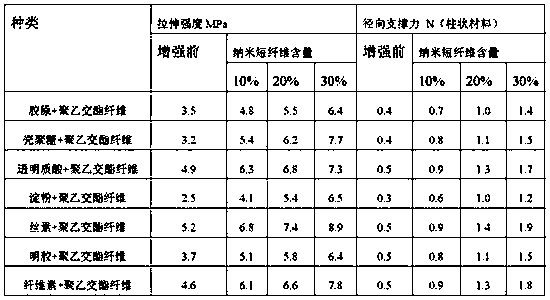

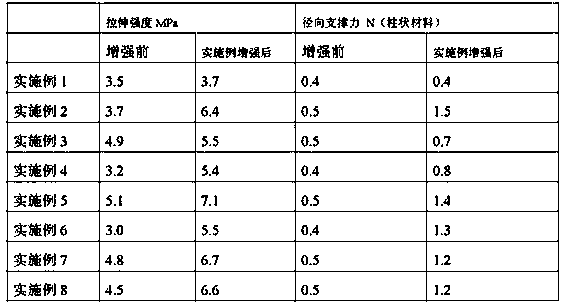

Examples

preparation example Construction

[0035]The present invention also includes a preparation method of medical nanofiber-reinforced hydrophilic composite material, comprising the following steps:

[0036] ①The polyester material is prepared into nanofibers with a diameter of 200-800nm by electrospinning method, and then the nanofibers are placed in liquid nitrogen below -100°C for 2-3 hours, crushed by a high-speed pulverizer and sieved. Obtain short nanofibers with a length of 10-100 μm;

[0037] The polyester material is any one of polylactide, polyglycolide, polycaprolactone, polytrimethylene carbonate and polydioxanone, or a mixture of any two or more of them;

[0038] ②Use a solvent to configure the hydrophilic base material into a solution with a mass concentration of 0.1-20%, add the nano-short fibers obtained in step ① to it, stir and disperse evenly, and obtain a mixed solution, put the mixed solution into a mold to freeze and form, and then place Freeze-dry in a freeze dryer to remove the solvent to ...

Embodiment 1

[0049] A medical nanofiber-reinforced hydrophilic composite material, the composite material is composed of a hydrophilic base material and nano-short fibers, the nano-short fibers maintain a crystalline form and are uniformly dispersed in the hydrophilic base material, and the nano-short fibers are in the composite material The mass percentage is 1%; the hydrophilic basic material is collagen; the nano-short fiber is a polyester material, and the polyester material is polylactide; the diameter of the nano-short fiber is 200nm, and the length is 10 μm .

Embodiment 2

[0051] A medical nanofiber-reinforced hydrophilic composite material, the composite material is composed of a hydrophilic base material and nano-short fibers, the nano-short fibers maintain a crystalline form and are uniformly dispersed in the hydrophilic base material, and the nano-short fibers are in the composite material The mass percentage is 30%; the hydrophilic basic material is gelatin; the nano-short fiber is a polyester material, and the polyester material is polyglycolide; the diameter of the nano-short fiber is 350nm, and the length is 30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com