Method for preparing vertical transition metal sulfide nanosheet array and electro-catalysis hydration separation catalyst

A metal sulfide and nanosheet array technology, applied in the field of electrocatalytic hydrogen evolution, can solve the problems of high energy consumption, random thickness, surface adsorption pollution, etc., and achieve the effects of reducing energy consumption, shortening time, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

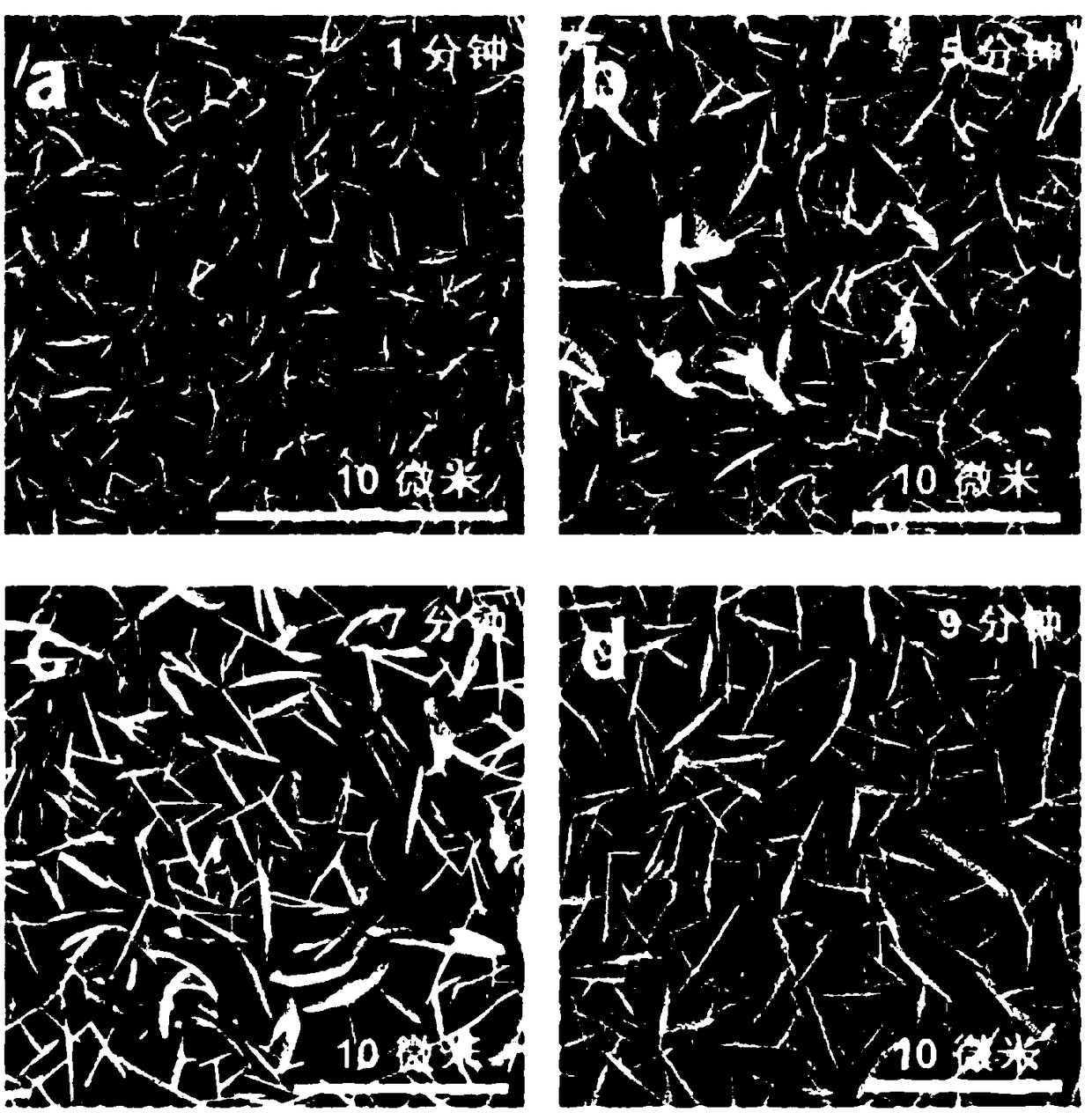

Embodiment 1

[0054] Cut the purchased commercial gold-silver alloy foil (1 cm ╳ 1 cm, thickness 700 nanometers), and then chemically etch the porous gold film. The etching method is: 700 nanometers thick gold-silver alloy The foil was etched in concentrated nitric acid for 4 hours, and the residual nitric acid was subsequently rinsed with deionized water to complete the preparation of porous gold. Gold foil is used as the supporting substrate of the porous gold film, and the cleaned porous gold film is picked up from the water surface with gold foil to obtain the growth substrate. The prepared growth substrate is placed in a high-temperature tubular reaction chamber, and tantalum pentachloride and sulfur powder are placed in sequence in the upstream of the airflow relative to the substrate. The distance between the sulfur powder and the tantalum pentachloride is 1-2 cm, and the distance between the tantalum pentachloride and the substrate 8 to 10 centimeters, of which the masses of sulfur ...

Embodiment 2

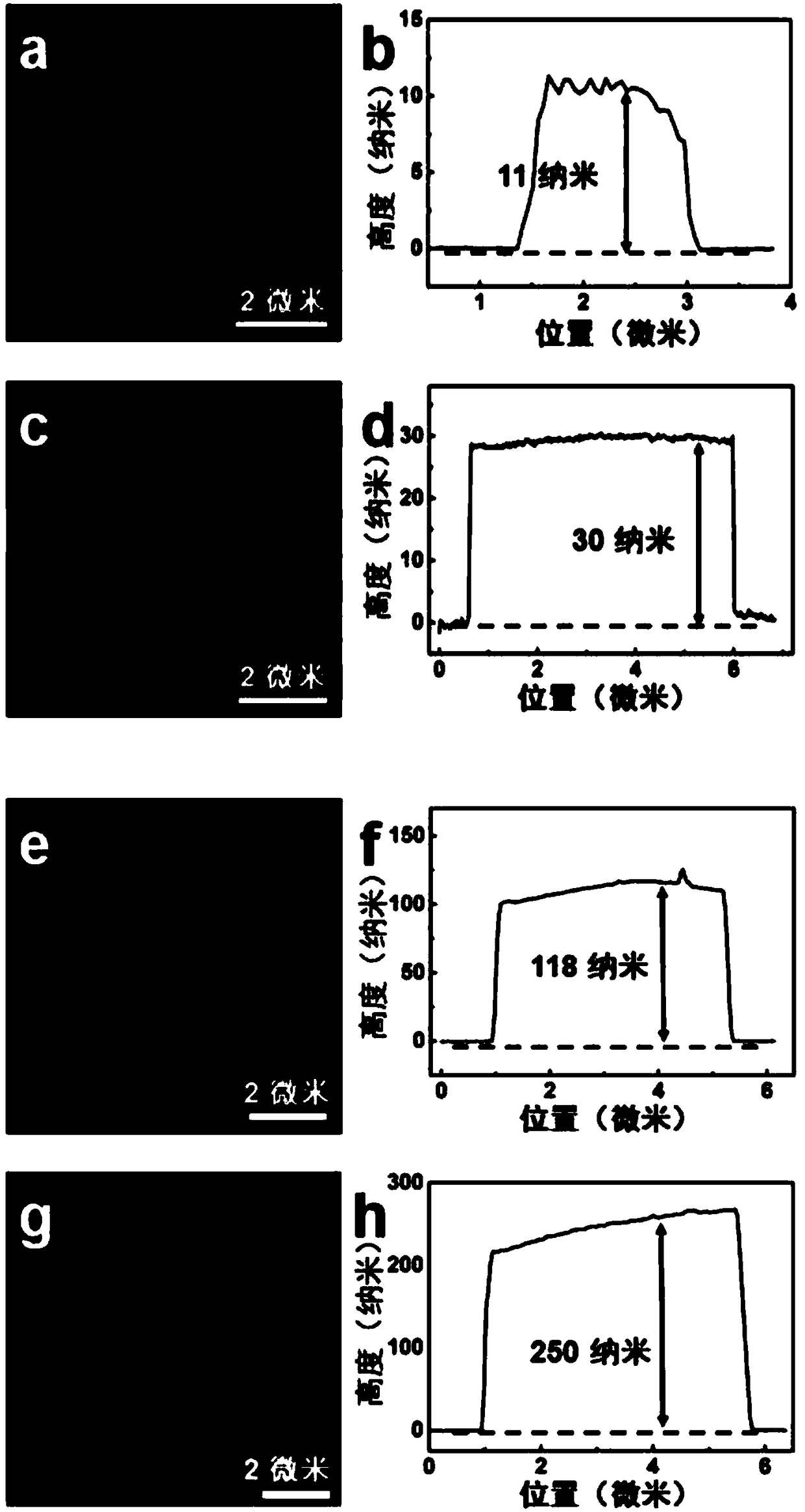

[0057] The thickness of the tantalum disulfide nanosheets prepared in Example 1 was characterized by atomic force microscopy. The prepared vertical tantalum disulfide nanosheets can be attached to the surface of the required substrate by pressing the surface of the required substrate face-to-face with the substrate for growing tantalum disulfide. The method can effectively avoid the pollution problem in the traditional polymer-assisted transfer method. The thickness of tantalum disulfide nanosheets can be adjusted from 18 nm to 300 nm with different growth times, and the lateral size can reach 5 microns. The topography and height maps of the atomic force microscope are respectively figure 2 a-h.

Embodiment 3

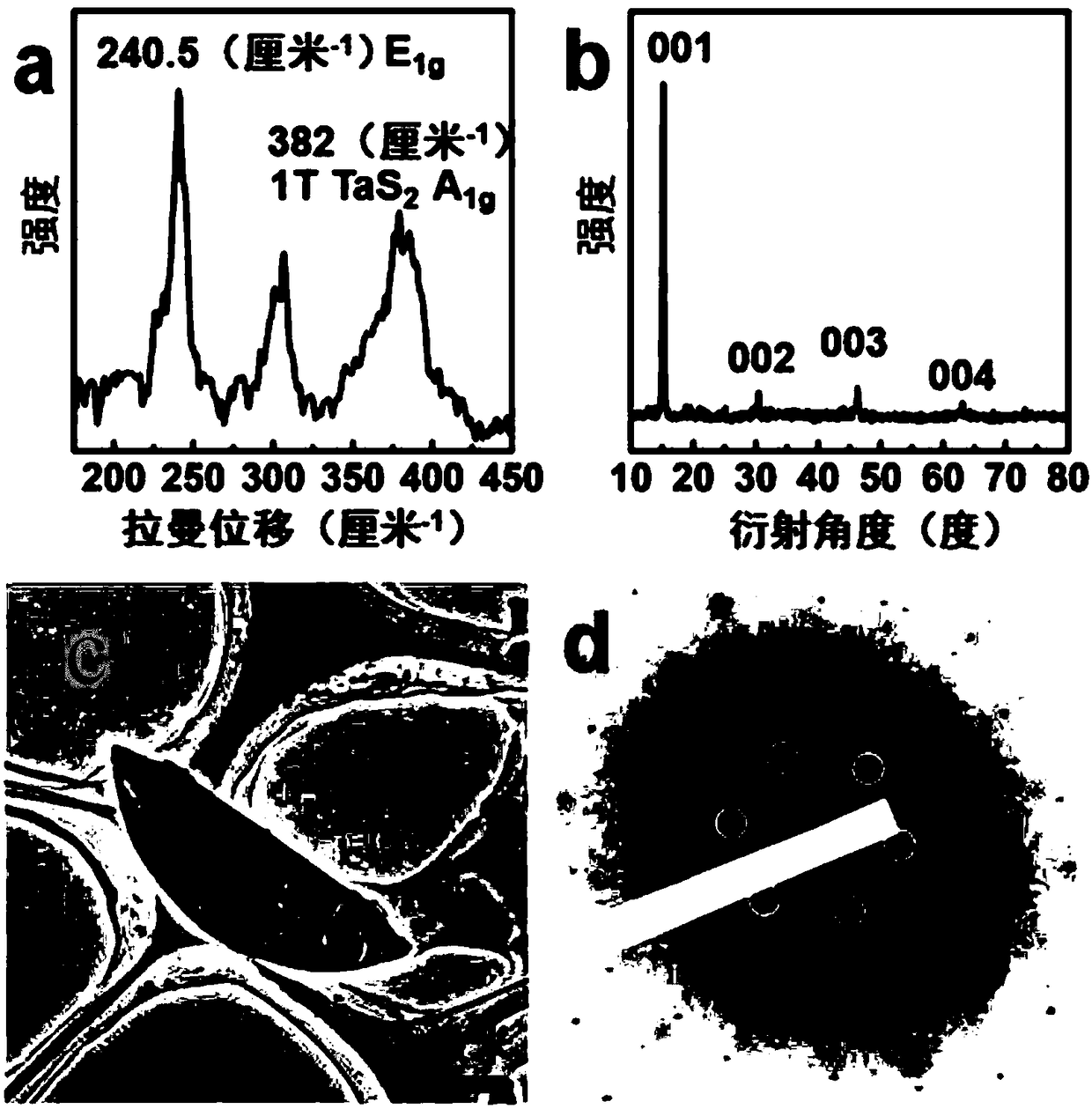

[0059] The tantalum disulfide nanosheets prepared in Example 1 have been tested by Raman spectrum, X-ray diffraction, and transmission electron microscopy, and the results are as follows: image 3 shown. Raman spectroscopy test shows that the prepared tantalum disulfide nanosheets are tantalum disulfide nanosheets with 1T phase structure. X-ray diffraction also shows that the prepared nanosheets are tantalum disulfide nanosheets with high crystalline quality and 1T phase structure. Transmission electron microscopy test shows that the prepared nanosheets are tantalum disulfide nanosheets with good crystal quality.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com