Porous carbon nanofiber/special engineering plastic composite and preparation method thereof

A technology of special engineering plastics and nano-carbon fibers, which is applied in the fields of fiber chemical characteristics, chemical post-treatment of rayon, textiles and papermaking, etc. It can solve the problems of inability to infiltrate and improve material properties, and achieve improved infiltration and good chemical stability. , Improve the effect of permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

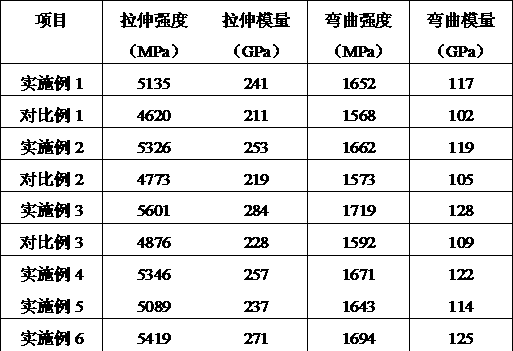

Examples

Embodiment 1

[0034]The method for preparing porous nano-carbon fiber / special engineering plastic composite material in this embodiment specifically includes the following steps:

[0035] Step (1): Mix polyacrylonitrile, pore-forming agent, tubular nano halloysite and N,N-dimethylformamide to prepare spinning solution;

[0036] Step (2): Electrospinning is carried out using the spinning solution prepared in step (1), followed by carbonization, and then washed with hot alkali and dried to obtain porous nano-carbon fibers;

[0037] Step (3): Disperse the porous nano-carbon fibers prepared in step (2) in a concentrated acid solution, transfer to deionized water after cooling, stir, centrifuge, remove the supernatant, and continue to wash with deionized water until The pH of the supernatant is neutral, and the porous carbon nanofibers with surface acidification are prepared;

[0038] Step (4): impregnating the surface-acidified porous carbon nanofibers prepared in step (3) into a resin matrix ...

Embodiment 2

[0055] The method for preparing porous nano-carbon fiber / special engineering plastic composite material in this embodiment specifically includes the following steps:

[0056] Step (1): Mix polyacrylonitrile, pore-forming agent, tubular nano halloysite and N,N-dimethylformamide to prepare spinning solution;

[0057] Step (2): Electrospinning is carried out using the spinning solution prepared in step (1), followed by carbonization, and then washed with hot alkali and dried to obtain porous nano-carbon fibers;

[0058] Step (3): Disperse the porous nano-carbon fibers prepared in step (2) in a concentrated acid solution, transfer to deionized water after cooling, stir, centrifuge, remove the supernatant, and continue to wash with deionized water until The pH of the supernatant is neutral, and the porous carbon nanofibers with surface acidification are prepared;

[0059] Step (4): impregnating the surface-acidified porous carbon nanofibers prepared in step (3) into a resin matrix...

Embodiment 3

[0076] The method for preparing porous nano-carbon fiber / special engineering plastic composite material in this embodiment specifically includes the following steps:

[0077] Step (1): Mix polyacrylonitrile, pore-forming agent, tubular nano halloysite and N,N-dimethylformamide to prepare spinning solution;

[0078] Step (2): Electrospinning is carried out using the spinning solution prepared in step (1), followed by carbonization, and then washed with hot alkali and dried to obtain porous nano-carbon fibers;

[0079] Step (3): Disperse the porous nano-carbon fibers prepared in step (2) in a concentrated acid solution, transfer to deionized water after cooling, stir, centrifuge, remove the supernatant, and continue to wash with deionized water until The pH of the supernatant is neutral, and the porous carbon nanofibers with surface acidification are prepared;

[0080] Step (4): impregnating the surface-acidified porous carbon nanofibers prepared in step (3) into a resin matrix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com