Solvent-free polyurethane floor paint and preparation method thereof

A solvent-free polyurethane and floor paint technology, used in polyurea/polyurethane coatings, coatings, etc., can solve the problems of short gel time, short construction time, hard paint film, etc., achieve comprehensive mechanical properties and reduce construction costs , excellent mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

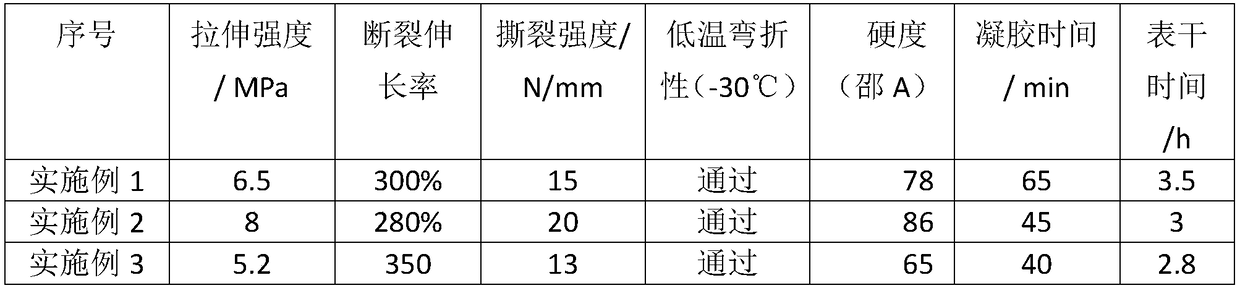

Examples

Embodiment 1

[0029] A solvent-free polyurethane floor paint, including main paint and curing agent;

[0030] Curing agent: polyether polyol 220A modified carbodiimide-uretonimine modified 4,4'-diphenylmethane diisocyanate, the isocyanate content is 12.5%.

[0031] The main paint includes 25 parts of polycaprolactone polyol, 28 parts of castor oil, 8 parts of 1,4-butanediol, 0.3 parts of polysiloxane defoamer, 0.2 part of polyacrylic acid leveling agent, and 0.1 part of bentonite , 0.2 parts of polycarboxylic acid dispersant, 34.2 parts of microsilica powder and 4 parts of talcum powder;

[0032] The preparation method of above-mentioned solvent-free polyurethane floor paint is as follows (each component content is added according to above-mentioned formula):

[0033] (1) Pour polyether polyol 220A into the kettle, stir and heat to 85°C, depressurize and evacuate to -0.13Mpa, and dehydrate for 1 hour;

[0034] (2) Cool down to 60°C, pour carbodiimide-uretonimine modified 4,4'-diphenylmeth...

Embodiment 2

[0041] A solvent-free polyurethane floor paint, including main paint and curing agent;

[0042] Curing agent: polyether polyol DL-1000D modified polymethylene polyaryl isocyanate, the isocyanate content is 13.2%.

[0043] The main paint includes 52 parts of castor oil modified polyol, 8 parts of diethylene glycol, 0.4 part of polyacrylic acid defoamer, 0.2 part of silicone leveling agent, 0.1 part of bentonite, 0.2 part of fatty acid dispersant, 30 parts of barium sulfate and 9.1 parts of heavy calcium powder;

[0044] The preparation method of above-mentioned solvent-free polyurethane floor paint is as follows (each component content is added according to above-mentioned formula):

[0045] (1) Pour the polyether polyol DL-1000D into the kettle, stir and heat to 90°C, depressurize and evacuate to -0.15Mpa, and dehydrate for 1.5 hours;

[0046] (2) Cool down to 60°C, pour polymethylene polyaryl isocyanate, stir and keep warm at 80-85°C for 2 hours;

[0047] (3) the isocyanat...

Embodiment 3

[0053] A solvent-free polyurethane floor paint, including main paint and curing agent;

[0054] Curing agent: polyether polyol 330N modified polymethylene polyaryl isocyanate, the isocyanate content is 14%.

[0055] The main paint includes 30 parts of polyester polyol SOVERMOL705, 25 parts of modified castor oil, 9 parts of dimethylthiotoluenediamine, 0.4 part of polyacrylic acid defoamer, 0.2 part of polyacrylic leveling agent, 0.2 part of hydrogenated castor oil part, 0.2 part of aliphatic amide dispersant, 35 parts of barium sulfate;

[0056] The preparation method of above-mentioned solvent-free polyurethane floor paint is as follows (each component content is added according to above-mentioned formula):

[0057] (1) Pour polyether polyol 330N into the kettle, stir and heat to 90°C, depressurize and evacuate to -0.15Mpa, and dehydrate for 2 hours;

[0058] (2) Cool down to 60°C, pour polymethylene polyaryl isocyanate, stir and keep warm at 80-85°C for 2 hours;

[0059] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com