Magnetic biochar material for heavy metal waste water treatment and preparation method of magnetic biochar material

A biochar, heavy metal technology, applied in the directions of alkali metal compounds, water/sewage treatment, adsorbed water/sewage treatment, etc., can solve the problems of difficult solid-liquid separation and difficult recycling of materials, and achieve good photocatalytic performance and excellent adsorption. Effects, effects that are easy to mass produce

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

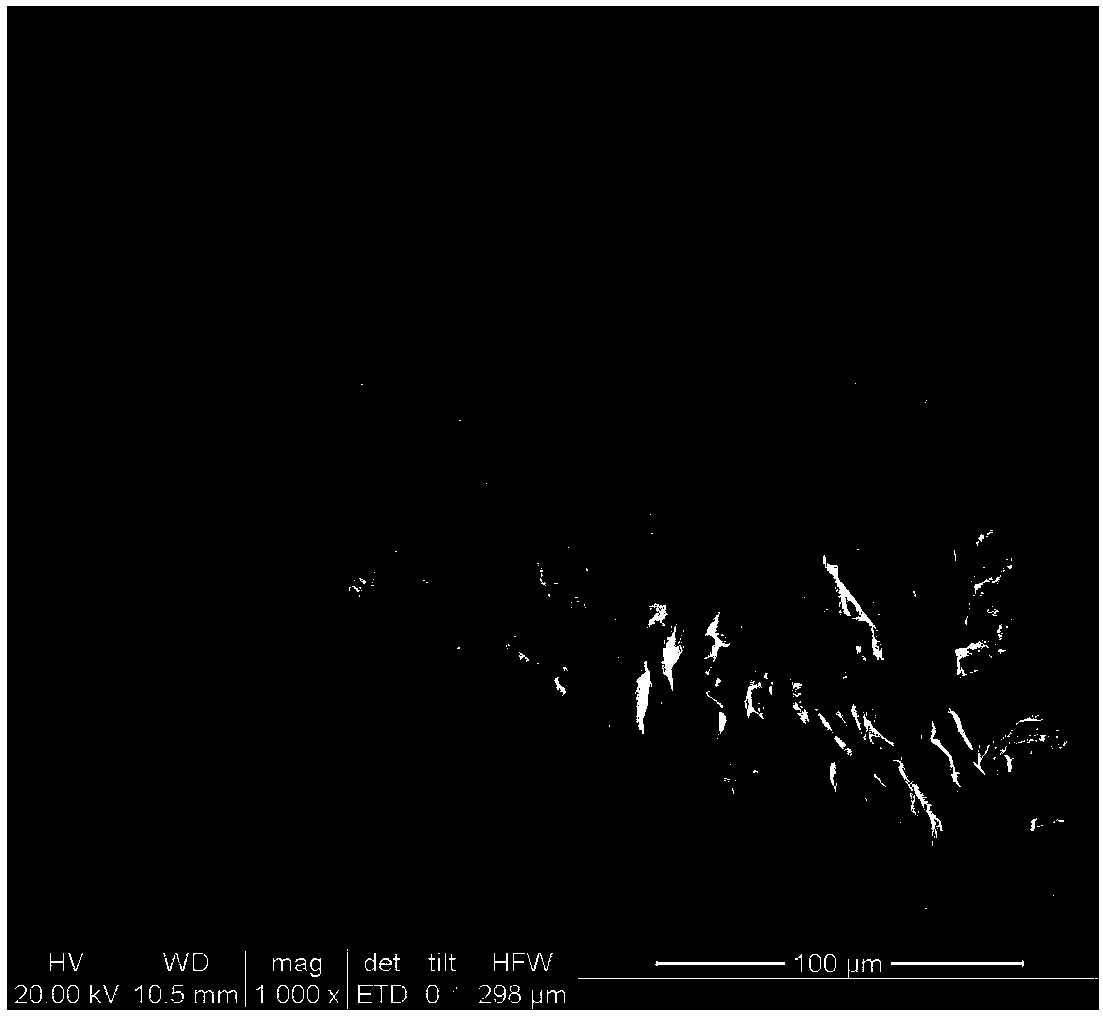

[0020] A magnetic biochar material of the present invention is characterized in that the crosslinked chitosan gel is used as a carrier, and the gel is evenly loaded with magnetic BiFeO 3 Materials and molecules of kenaf biochar with high porosity. The magnetic biochar material is prepared by the following method:

[0021] (1) Weigh 0.08mol of ferric nitrate, 0.08mol of bismuth nitrate and 0.08mol of citric acid, the ratio is 1:1:1, dissolve the weighed solid ferric nitrate and bismuth nitrate in 200mL of ethylene glycol methyl Add 0.2 mL of nitric acid solution with a molar concentration of 0.1 mol / L to the ether, dissolve the weighed citric acid in 100 mL of ethylene glycol, mix the two solutions evenly, place the container containing the mixed solution in water at a temperature of 60°C Heating in a water bath for 1 hour, the obtained black solution was heated at a temperature of 100°C for 10 hours to obtain a light brown gel, which was put into a crucible and placed in a mu...

Embodiment 2

[0026] The magnetic biochar material of the present invention is used to remove hexavalent chromium ions in wastewater, comprising the following steps:

[0027]Take five parts of wastewater with a mass concentration of hexavalent chromium ions of 50mg / L, each with a volume of 50mL, put them in a clean Erlenmeyer flask, and adjust the pH to 2, 4, 6, 8, 10 with hydrochloric acid and sodium hydroxide solution, respectively. After labeling, the magnetic biochar material prepared in Example 1 is added to the waste water sample, and the dosage of the material in every liter of waste water is 4g, and the sealed Erlenmeyer flask is placed in a rotating speed of 150rpm as a reactor. In the constant temperature oscillation box, the temperature in the box was maintained at 30°C, and after 4 hours of oscillation reaction, the material was separated from the solution with a magnet, and the adsorption treatment of hexavalent chromium ions in the wastewater sample was completed. Adopt diphen...

Embodiment 3

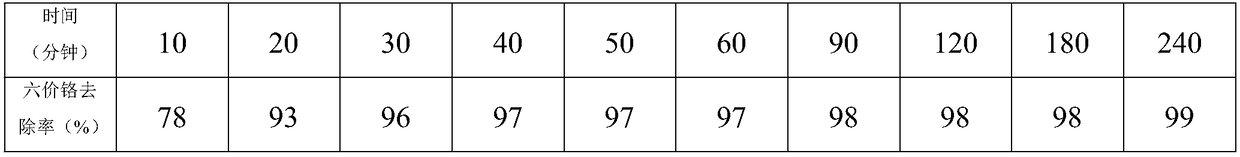

[0032] The magnetic biochar material of the present invention is used to remove hexavalent chromium ions in wastewater, comprising the following steps:

[0033] Get three parts of hexavalent chromium concentration and be respectively 10mg / L, 50mg / L, 100mg / L waste water test solution, be placed in clean Erlenmeyer flask, adjust pH to be 2 with hydrochloric acid solution, after labeling is finished, embodiment 1 is made The magnetic biochar material is added to the wastewater sample, and the dosage of the material per liter of wastewater is 4g. The sealed Erlenmeyer flask is used as a reactor and placed in a constant temperature oscillation box with a rotation speed of 150rpm, and the temperature in the box is maintained at 30°C, oscillating for 4 hours and then using a magnet to separate the material from the solution to complete the adsorption treatment of hexavalent chromium ions in the wastewater sample. Adopt diphenylcarbazide spectrophotometry to measure the amount of unad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com