Single-component high-temperature glue and preparation method thereof

A high-temperature adhesive and component technology, applied in adhesives, epoxy resin glue, non-polymer adhesive additives, etc., can solve problems such as unsuitable structural viscosity, poor product consistency, insufficient viscosity strength, etc., to achieve quality Good consistency, long life, and wide range of applicable materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0033] The preparation method of the single-component high-temperature glue provided by the present invention has the following steps:

[0034] Step 1: Weigh the Portions

[0035] Weigh each component according to the ratio of the single-component high-temperature glue, wherein, according to the needs, select the component of the auxiliary agent, and determine the proportion of each component;

[0036] Step 2: Stir once

[0037] Put the modified maleimide resin, liquid epoxy resin, reactive diluent, and antioxidant into the reaction kettle, and stir at a speed of 40-100rpm under nitrogen at 80-100°C until completely mixed. dissolve into a homogeneous liquid;

[0038] Step 3: Second Stirring

[0039] If a dispersing paddle is installed in the reactor, the homogeneous liquid can be dispersed, and the dispersing speed is 100-3000rpm. Then cool down the homogeneous liquid to 50-60°C, add the pigments and fillers, coupling agents and defoamers, and stir in vacuum for 30-60min; ...

Embodiment 1

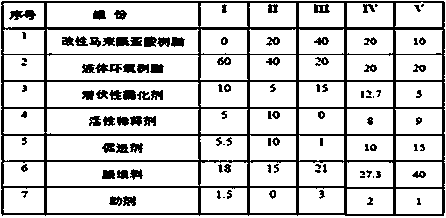

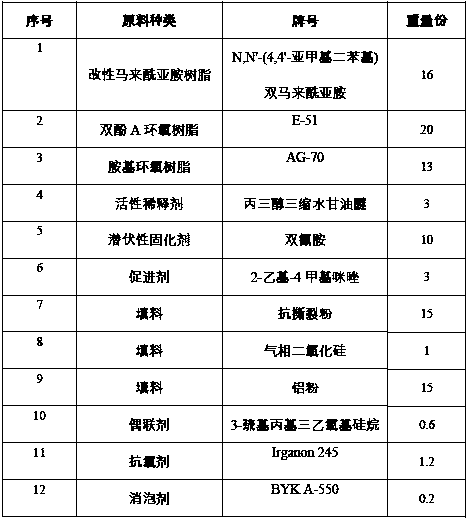

[0052] The present embodiment is formulated from the following raw materials in weight percentage:

[0053]

[0054] According to the above weight percentage formula, the process steps of preparing one-component high-temperature adhesive are as follows:

[0055] (1) Resin miscibility: Bisphenol A epoxy resin E-51, amino epoxy resin AG-70, glycerol triglycidyl ether, N,N'-(4,4'-methylene di Phenyl)bismaleimide and Irganon 245 were put into a double-row mixer, and stirred at 80 rpm for 40 minutes under nitrogen at 100°C, and all materials were mixed into a homogeneous liquid. Lower the temperature to 50°C, add, anti-tear powder, fumed silica, alumina powder, 3-mercaptopropyltriethoxysilane, BYK A-550 and stir in vacuum for 40min at a stirring speed of 80rpm and a dispersion speed of 1500rpm. Cool down to 25°C, add dicyandiamide and 2-ethyl-4-methylimidazole, stir in vacuum for 40 minutes, and set aside.

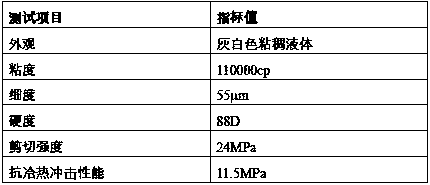

[0056] (2) Grinding: Grind the mixture in step (1) on a three-roll ma...

Embodiment 2

[0062] The present embodiment is formulated from the following raw materials in weight percentage:

[0063]

[0064] According to the above weight percentage formula, the process steps of preparing one-component high-temperature adhesive are as follows:

[0065] (1) Resin miscibility: Bisphenol A epoxy resin E-41, bisphenol F epoxy resin NPEF-170, trimethylolpropane triglycidyl ether, N,N'-m-phenylene bismaleyl The imine and antioxidant 1010 were put into the mixer, and stirred at 60 rpm and 100°C under nitrogen for 60 minutes, and all the materials were mixed into a homogeneous transparent liquid. Lower the temperature to 50°C, add carbon black, fumed silica, alumina powder, 3-glycidyloxypropyltrimethoxysilane, BYK A-550 and stir in vacuum for 60min at a stirring speed of 60rpm. Cool down to 25°C, add dicyandiamide and 2-ethyl-4-methylimidazole, stir in vacuum for 40 minutes, and set aside.

[0066] (2) Grinding: Grind the mixture in step (1) on a three-roll machine for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| epoxy value | aaaaa | aaaaa |

| Functional group degree | aaaaa | aaaaa |

| purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com