Preparation method of rare earth doped zirconia fluorescent marking material, product and application thereof

A technology of zirconium dioxide and fluorescent labeling, which is applied in the field of luminescent materials in luminescence physics, can solve the problems of concentration quenching, reduction of fluorescence emission intensity, interaction enhancement, etc., and achieve low cost, easy operation, and uniform particle distribution Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

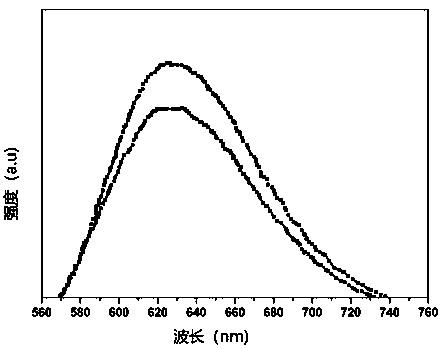

[0021] 0.2 mol zirconium salt ZrOCl 2 ﹒ 8H 2 O and 0.01mol erbium salt Er(ClO 4 ) 3 Add it into 15ml of deionized water, stir magnetically to dissolve the salt completely, then add acetic acid according to the molar ratio of the total molar amount of metal ions to the solvent amount of 1:100, and add reaction butenedioic acid to form a transparent solution, and magnetic stirring was carried out to make the solution evenly mixed, and the obtained solution was transferred into a glass bottle with a Teflon cap. Put the glass bottle containing the solution into a hydrothermal kettle that has been preheated at 120°C, and keep the temperature at a constant temperature for 24 hours. After the reaction, collect the reaction product, that is, the crystals at the bottom of the bottle, wash the crystals once with deionized water and ethanol, and dry them at room temperature to obtain Er-Zr-MOF powder. When the powder is excited by a 280nm laser, the luminescence peak is 620nm. No c...

Embodiment 2

[0023] 0.2 mol zirconium salt ZrOCl2﹒8H2O and 0.02mol erbium salt Er(ClO4) 3 Add it into 15ml of deionized water, stir magnetically to dissolve the salt completely, then add acetic acid according to the molar ratio of the total molar amount of metal ions to the solvent amount of 1:120, and add reaction butenedioic acid to form a transparent solution, and magnetic stirring was carried out to make the solution evenly mixed, and the obtained solution was transferred into a glass bottle with a Teflon cap. Put the glass bottle containing the solution into a preheated 120°C hydrothermal kettle, and keep the temperature at a constant temperature for 28 hours. After the reaction, collect the reaction product, that is, the crystals at the bottom of the bottle, wash the crystals once with deionized water and ethanol, and dry them at room temperature to obtain Er-Zr-MOF powder. When the powder is excited by a 280nm laser, the luminescence peak is 630nm. No concentration quenching pheno...

Embodiment 3

[0025] Add 0.2 mol of zirconium salt ZrOCl2.8H2O and 0.06 mol of erbium salt Er(ClO4)3 into 15ml of deionized water, stir magnetically to dissolve the salt completely, and then add Acetic acid, add fumaric acid according to the molar ratio of metal ion molar amount and solvent amount as 1:3, form a transparent solution, carry out magnetic stirring to make the solution mix evenly, transfer the obtained solution into a glass with a Teflon bottle cap in the bottle. Put the glass bottle containing the solution into a hydrothermal kettle that has been preheated at 120°C, and keep the temperature at a constant temperature for 36 hours. After the reaction, collect the reaction product, that is, the crystals at the bottom of the bottle, wash the crystals once with deionized water and ethanol, and dry them at room temperature to obtain Er-Zr-MOF powder. Under the excitation of 280nm laser, the powder has a luminescence peak of 610nm. No concentration quenching phenomenon occurred.

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com