Macroporous mayenite fluorescent material and preparation method thereof

A macroporous mayenite and fluorescent material technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problem of inability to obtain co-continuous hole structure and morphology, and achieve low cost, enhanced fluorescence intensity, and good luminous intensity. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-1

[0030] Embodiment 1-1, a method for preparing a macroporous mayenite block, the following steps are performed in sequence:

[0031] 1), at room temperature, dissolve 0.04 g of the phase separation inducer polyethylene oxide (PEO, with a molecular weight of 300,000) in a mixed solvent composed of 2.0 ml of water and 4.0 ml of ethanol (alcohol), stir magnetically, and then add as 2.000g aluminum chloride hexahydrate (AlCl 3 ·6H 2 O), 1.044g calcium chloride dihydrate (CaCl 2 2H 2 O), 1 g of terbium chloride nonahydrate (TbCl 3 9H 2 0), and adding 0.4ml of drying control agent (formamide), 0.3ml of chelating agent (ethylene glycol) and stirring for 60min, after stirring evenly, add 1.5ml of gel accelerator (concentration is 25% ammonia water) and ultrasonic for 60 seconds;

[0032] 2), put the uniform and transparent sol liquid obtained in step 1) in an airtight container, gel and age in an oven at 70°C for 24 hours;

[0033] 3) Place the aged white homogeneous gel obtained i...

Embodiment 1-2

[0037] Change the phase separation inducer in step 1) of Example 1-1---polyethylene oxide from 0.04g to 0.08g; the rest are the same as in Example 1-1.

[0038] Observation by scanning electron microscope at low and high magnifications shows that the obtained mayenite still has a coherent macropore structure, but with the increase of the amount of PEO, the diameter of the macropores decreases as ( figure 2 , about 0.6 μm), the porosity is 72%. This is due to the further progress of PEO phase separation. After the fluorescence test, its luminous intensity decreased slightly (such as Figure 4 ).

Embodiment 1-3

[0040] Change the phase separation inducer in step 1) of Example 1-1---polyethylene oxide from 0.04g to 0.12g; the rest are the same as in Example 1-1.

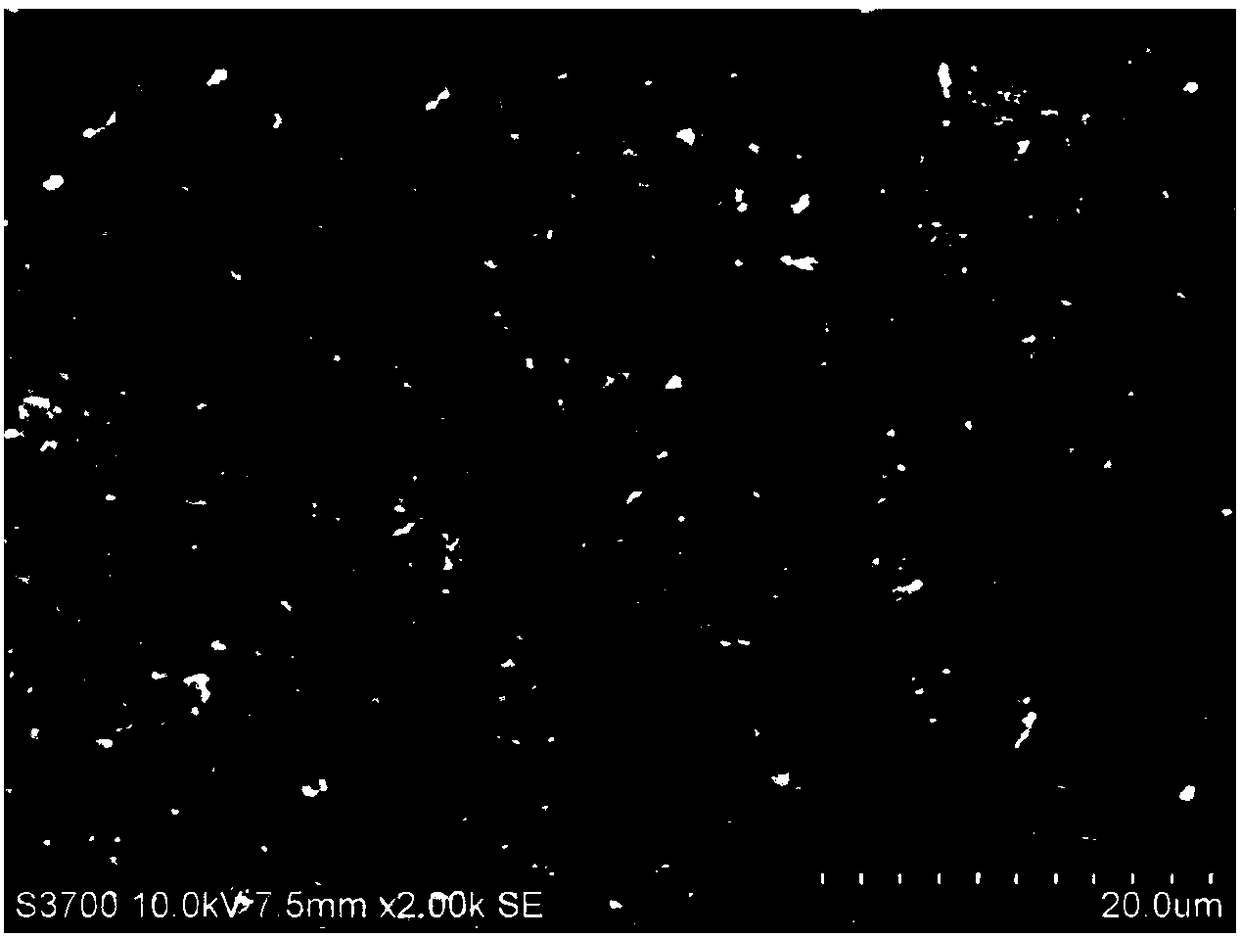

[0041] The low-power and high-power observations of the scanning electron microscope show that the microscopic morphology of the mayenite block has changed to the accumulation of mayenite particles, that is, it does not present a coherent macropore structure such as ( image 3 ), the porosity is 67%. This is because as the amount of PEO increases, the phase separation effect of PEO is further enhanced, and excessive phase separation occurs. After fluorescence test, its luminous intensity further decreased (such as Figure 4 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com